movement disappears or becomes less

severe, then the wheel hub bearings in the

swivel hub are at fault. Any perceptible

movement at all indicates wear in the hub

bearings, and they should be renewed as

described in Chapter 10.

Swivel hub balljoints

7 Wear of the swivel hub balljoints is fairly

common on Minis and will be quite obvious

on inspection because the whole swivel hub

will appear to move in relation to the

suspension arms as the wheel is rocked. If

this is the case, the balljoints should be

adjusted, or if badly worn, renewed; these

procedures are contained in Chapter 10.

Suspension arm mountings

8 Check for wear of the lower arm inner

mounting bushes where the arm is bolted to

the subframe. If the bushes are worn, the arm

will appear to move in and out as the wheel is

rocked.

9 The upper arm inner roller bearings cannot

be inspected without partially dismantling the

suspension because the rubber cone spring

or displacer unit holds the arm in tension and

any wear will not be evident. It can be

removed for closer inspection if required as

described in Chapter 10; however, wear of the

upper arm and its bearings is uncommon.

10 With the brakes still firmly applied, try to

rotate the wheel back and forth. If any

movement is now felt, examine the tie-bar

between the lower suspension arm and

subframe for wear or deterioration of the

rubber bushes.

Rear suspension

11 To check the rear suspension for wear,

chock the front wheels then jack up the rear of

the car and support it on axle stands (see

“Jacking and vehicle support”).

12 Wear of the rear suspension components

can often be felt when driving the car as a

tendency for the rear of the vehicle to wander

over uneven road surfaces or when cornering.

To isolate the worn components, grasp the

roadwheel at the 12 o’clock and 6 o’clock

positions and try to rock it. If any movement is

felt, it is likely to be in one of the following

areas:

Hub bearings

13 Continue rocking the wheel while an

assistant depresses the footbrake. If the

movement disappears or becomes less

pronounced, then the bearings in the rear hub

are at fault. The bearings should be renewed if

there is any appreciable movement whatsoever.

Radius arm bearings

14 With the footbrake still applied, continue

rocking the wheel and observe the front of the

radius arm. If it can be seen to move

appreciably up and down, then wear has

taken place in the roller or plain bearing in the

radius arm, or on the pivot shaft. If this is the

case, the radius arm should be removed for

overhaul as described in Chapter 10.

6 Underbody and fuel/brake

line check

1

1 With the vehicle raised and supported on

axle stands (see “Jacking and vehicle

support”), or over an inspection pit,

thoroughly inspect the underbody and wheel

arches for signs of damage and corrosion. In

particular, examine the bottom of the side

sills, and any concealed areas where mud can

collect. Where corrosion and rust is evident,

press and tap firmly on the panel with a

screwdriver, and check for any serious

corrosion which would necessitate repairs. If

the panel is not seriously corroded, clean

away the rust, and apply a new coating of

underseal. Refer to Chapter 11 for more

details of body repairs.

2 At the same time, inspect the treated lower

body panels for stone damage and general

condition.

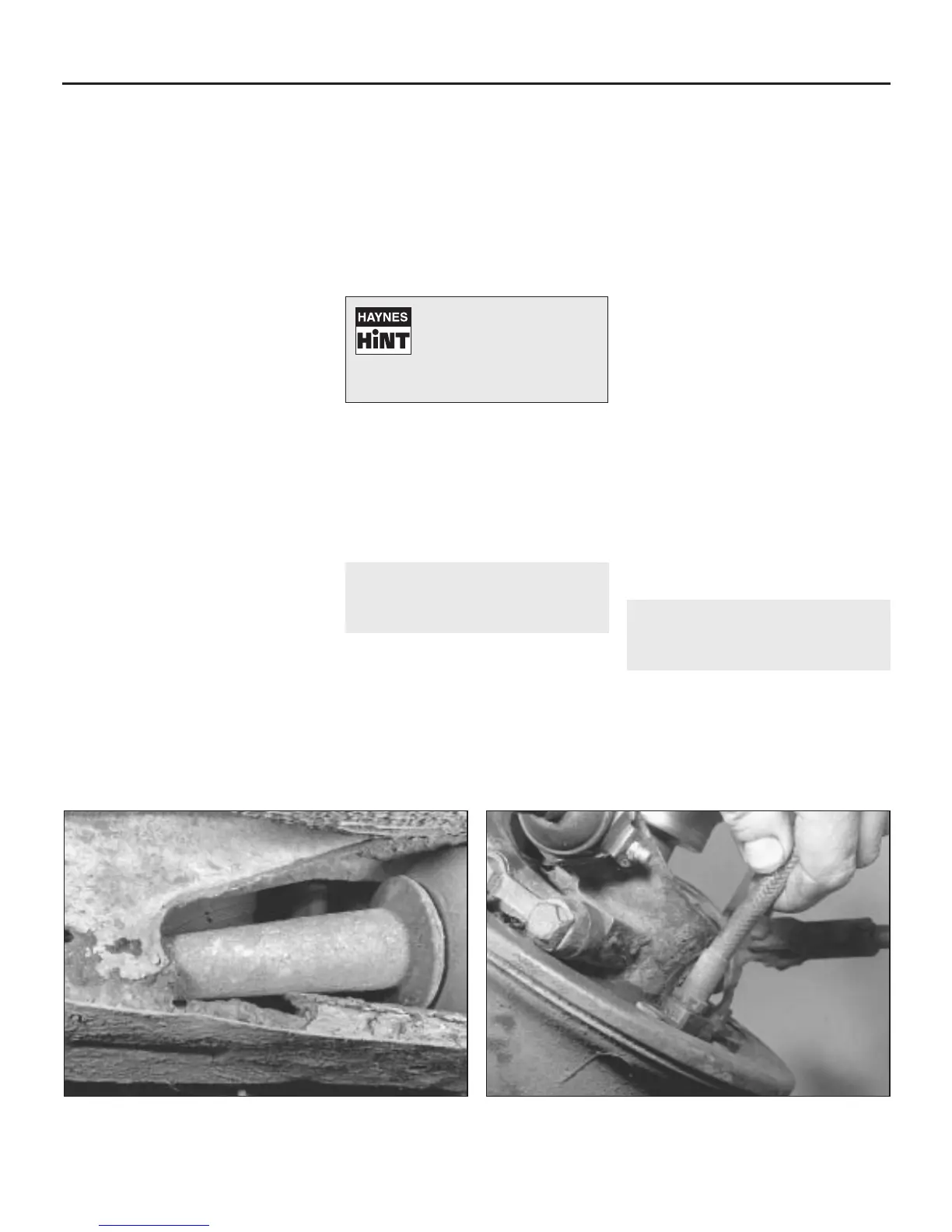

3 Examine the subframes carefully,

particularly the side members of the rear

subframe. Corrosion here is a common

occurrence on Minis, particularly older

models, and is one of the main causes of

MOT test failure on these cars (see

illustration). Where corrosion has reached an

advanced stage, renewal of the subframe is

the only satisfactory cure.

4 Inspect all of the fuel and brake lines on the

underbody for damage, rust, corrosion and

leakage. Also make sure that they are

correctly supported in their clips. The battery

positive cable which runs under the car from

front to rear is a common problem area as it is

prone to damage or chafing if not properly

routed or secured.

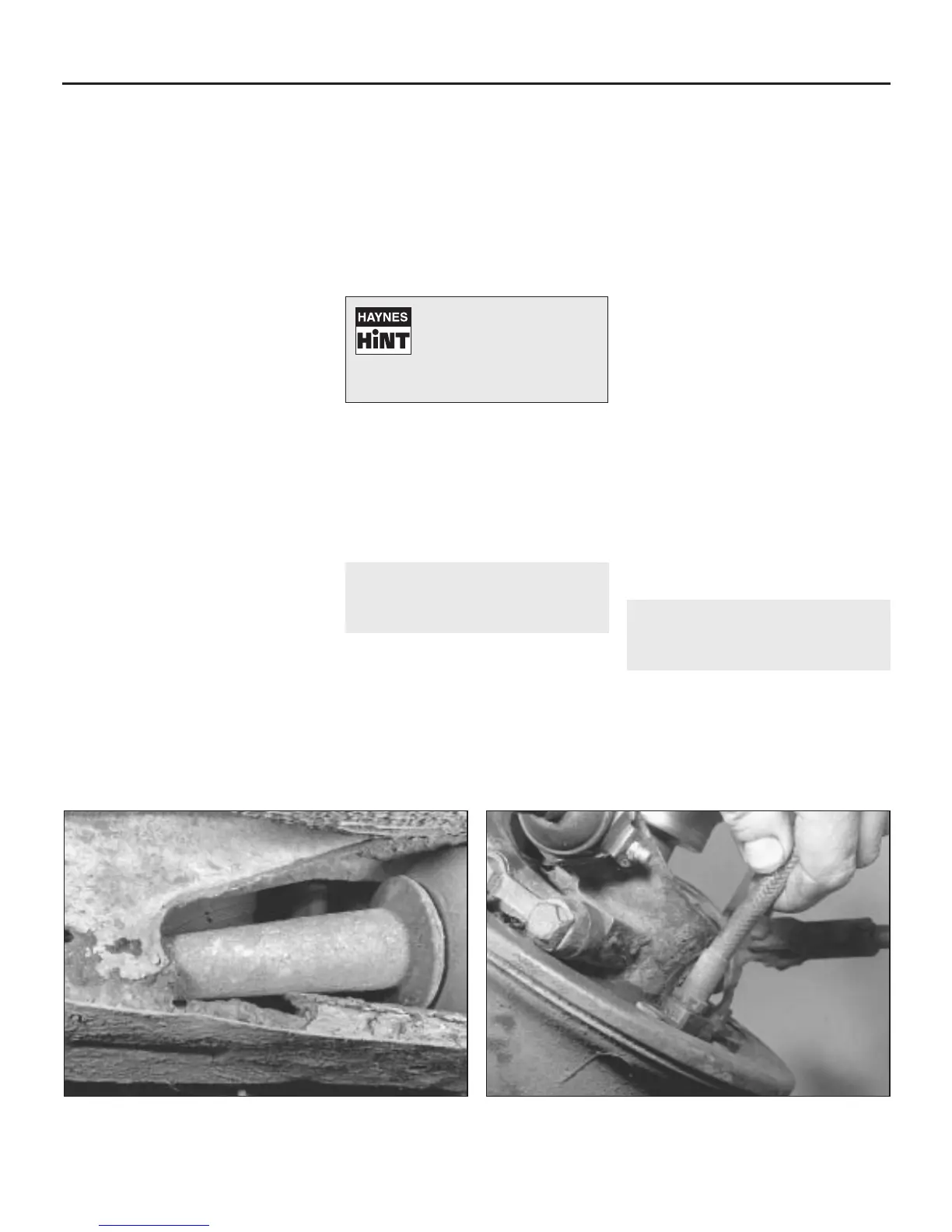

5 Inspect the flexible brake hoses in the

vicinity of the backplates or front calipers,

where they are subjected to most movement

(see illustration). Bend them between the

fingers (but do not actually bend them double,

or the casing may be damaged) and check

that this does not reveal previously hidden

cracks, cuts or splits.

7 Exhaust system check

1

1 With the engine cold (at least three hours

after the vehicle has been driven), check the

complete exhaust system, from its starting

point at the engine to the end of the tailpipe.

Ideally, this should be done on a hoist, where

unrestricted access is available; if a hoist is not

available, raise and support the vehicle on axle

stands (see “Jacking and vehicle support”).

1•10 Every 3000 miles or 3 months

6.3 Advanced state of corrosion on rear subframe side member 6.5 Inspect the flexible brake hoses in the vicinity of the

backplates

Wear in the rear hub bearings

can often be confirmed by

slowly turning the wheel with

your hand on the tyre. Worn

bearings usually exhibit a roughness

which can be felt as the wheel is turned.

Loading...

Loading...