2 Check the pipes and connections for

evidence of leaks, severe corrosion, or

damage. Make sure that all brackets and

rubber mountings are in good condition, and

tight; if any of the mountings are to be

renewed, ensure that the replacements are of

the correct type. Failure of the rear mounting

rubber blocks on the rear subframe is a

common problem - check these carefully (see

illustrations). Leakage at any of the joints or in

other parts of the system will usually show up

as a black sooty stain in the vicinity of the leak.

3 At the same time, inspect the underside of

the body for holes, corrosion, open seams,

etc. which may allow exhaust gases to enter

the passenger compartment. Seal all body

openings with silicone or body putty.

4 Rattles and other noises can often be

traced to the exhaust system, especially the

rubber mountings. Try to move the system,

silencer(s) and catalytic converter. If any

components can touch the body or

suspension parts, secure the exhaust system

with new mountings.

8 Fan belt check and renewal

2

Note: If the car is fitted with exhaust emission

control equipment it will first be necessary to

remove the air pump drivebelt as described in

Section 9 to allow access to the fan belt.

Check and adjustment

1 Release the three retaining lugs and remove

the engine ignition shield, if fitted. Rotate the

crankshaft so that the entire length of the fan

belt can be examined. On manual

transmission models, the engine can be

rotated quite easily by engaging top gear and

moving the car backwards or forwards to

allow the belt to be inspected. This should

only be done on level ground; and make sure

that the car cannot run away! An alternative

method, and the method that should be used

on automatic transmission models, is to press

the fan belt midway between the water pump

pulley and dynamo or alternator pulley and

then turn the fan blades.

2 Examine the belt for cracks, splitting,

fraying or damage. Check also for signs of

glazing (shiny patches) and for separation of

the belt plies. Renew the fan belt if worn or

damaged.

3 If the condition of the belt is satisfactory,

check the adjustment as follows.

4 It is most important to keep the fan belt

correctly adjusted; If the belt is too loose it will

slip and wear rapidly, resulting in inefficient

operation of the water pump and dynamo or

alternator. If it is too tight, it will impose

excessive strain on the bearings of the water

pump, dynamo or alternator causing

premature failure of these components.

5 The fan belt tension is correct when there

is 13 mm of fan belt deflection, using light

finger pressure, at a point midway between

the crankshaft and dynamo or alternator

pulleys.

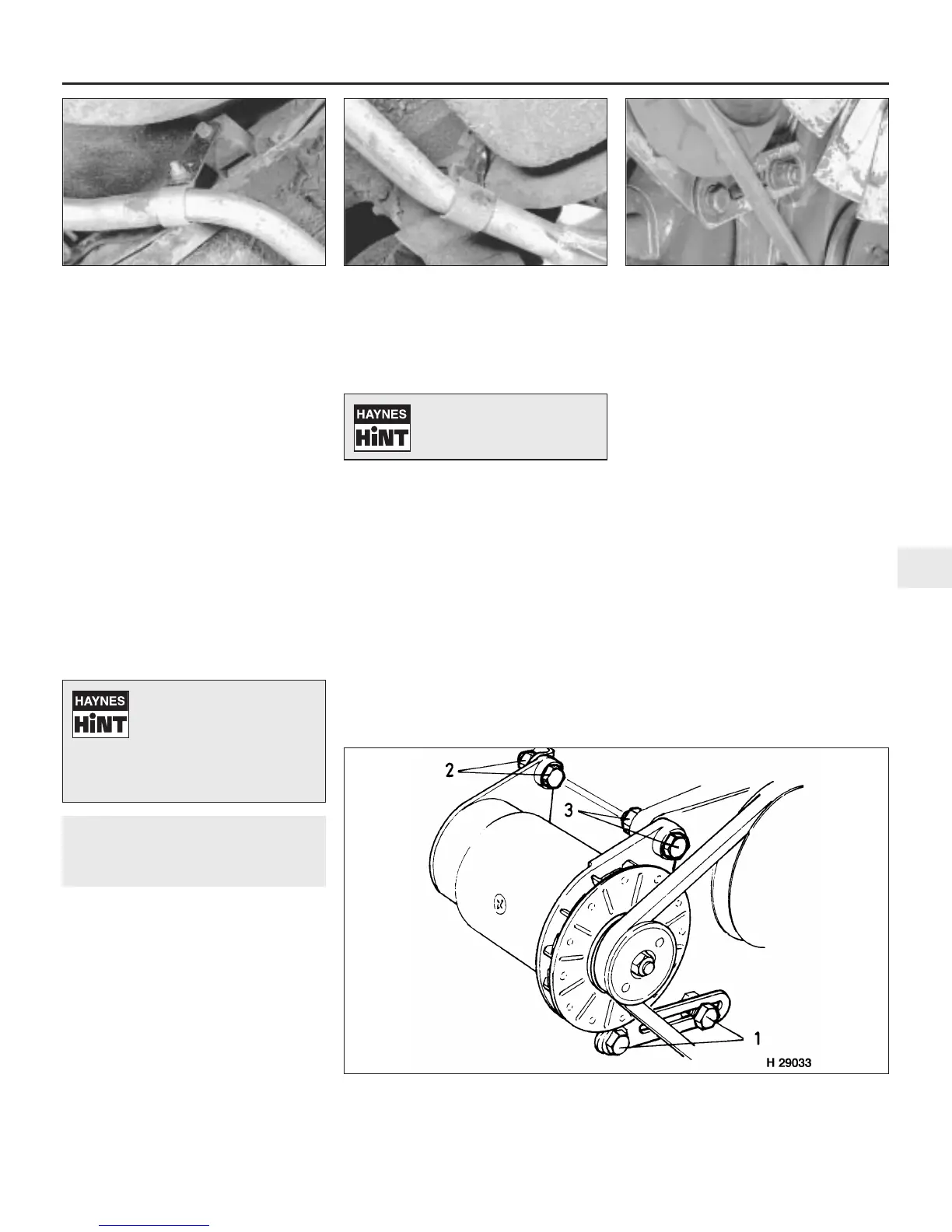

6 To adjust the fan belt, slacken the mounting

bolts of the dynamo or alternator, and also the

nut on the adjusting arm located below the

water pump (see illustration). Now move the

unit either in or out until the correct tension is

obtained. It is easier if the adjusting arm nut is

only slackened a little so it requires some force

to move the dynamo or alternator. In this way

the tension of the belt can be arrived at more

quickly than by making frequent adjustments.

If difficulty is experienced in moving the

dynamo or alternator away from the engine, a

long spanner or bar placed behind the unit and

resting against the block serves as a very good

lever and can be held in position while the

adjusting and mounting bolts are fully

tightened. When levering on an alternator, only

lever on the drive end or damage may occur.

7 When the tension is correct, tighten the

adjusting arm nut first, followed by the

mounting bolts.

Renewal

8 To remove the fan belt, slacken the two

dynamo or alternator upper mountings and

the nut on the adjusting arm below the water

pump (see illustrations).

Every 3000 miles or 3 months 1•11

1

8.6 Dynamo adjusting arm nut located

below the water pump

7.2a Exhaust front mounting block . . . 7.2b . . . and rear mounting block on rear

subframe

8.8a Dynamo mountings and adjustment points

1 Adjustment arm retaining nuts

2 Securing nut and bolt (rear)

3 Securing nut and bolt (front)

When checking the exhaust,

pay particular attention to the

mounting on the transmission.

Movement of the engine

causes this mounting to work loose,

causing an annoying squeak or rattle

when accelerating and decelerating.

Turning the engine will be

easier if the spark plugs are

removed first - see Section 33.

Loading...

Loading...