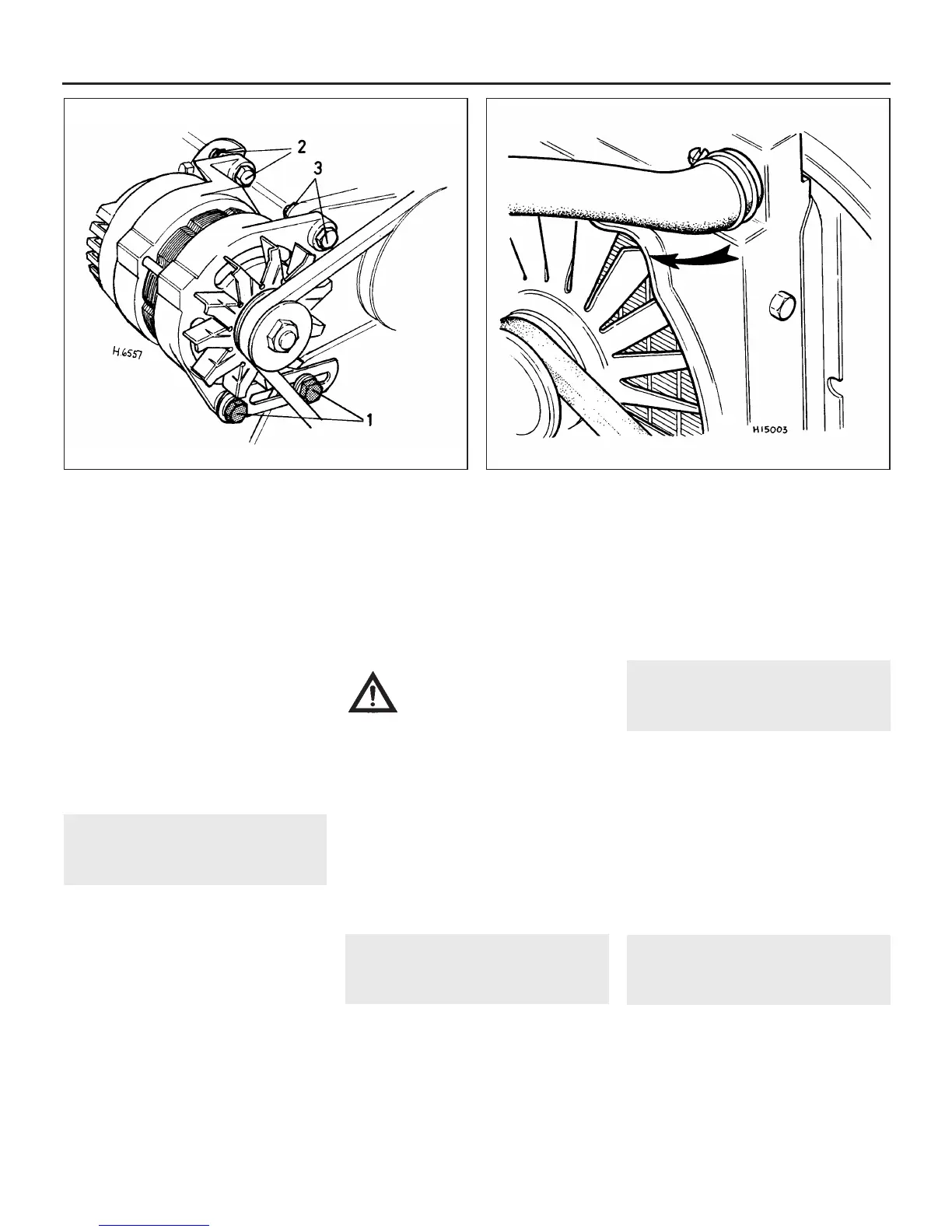

9 Push the dynamo or alternator toward the

engine and lift the old belt off the three

pulleys. Feed the belt over each fan blade in

turn and withdraw it from behind the fan

cowling at the special gap just below the top

hose (see illustration).

10 Fit the new belt over the fan blades in the

same way and then place it in position on the

three pulleys.

11 Adjust the fan belt tension as described

previously then refit the air pump drivebelt,

where applicable, as described in the

following Section. Note: After fitting a new fan

belt, check and if necessary readjust the

tension after 250 miles (400 km).

9 Air pump drivebelt check

and renewal

2

Check and adjustment

1 The checks and adjustment procedure for

the air pump drivebelt are basically the same

as described in Section 9 for the fan belt.

Adjust the tension of the drivebelt so that

there is 13 mm deflection of the belt, using

thumb pressure, at a point midway between

the two pulleys.

Renewal

2 Release the three retaining lugs and remove

the engine ignition shield, if fitted.

3 Undo and remove the two bolts securing

the radiator upper mounting bracket to the

radiator.

4 Unscrew the radiator filler cap and slacken

the top hose securing clips. Carefully ease the

radiator as far as possible toward the wing

valance. Place a container beneath the engine

to catch the small quantity of coolant that will

be lost as the top hose is released.

Warning: If the engine is hot,

take precautions against

scalding.

5 Slacken the air pump pivot and adjusting

link bolts, push the pump in toward the

engine, and slip the drivebelt off the two

pulleys.

6 Feed the belt between the fan blades and

the radiator cowling at the top as the blades

are rotated. Now pull the belt out from

between the fan and radiator.

7 Refitting the drivebelt is the reverse

sequence to removal, adjusting the tension as

described previously. Top up the cooling

system as described in “Weekly Checks” on

completion.

10 Clutch hydraulic check

1

1 Check that the clutch pedal moves

smoothly and easily through its full travel, and

that the clutch itself functions correctly, with

no trace of slip or drag.

2 Apply a few drops of light oil to the clutch

pedal pivot.

3 From within the engine compartment check

the condition of the fluid lines and hoses.

Check for signs of fluid leaks around the slave

cylinder rubber boot or from the feed pipe and

hose. Apply a few drops of oil to the clutch

operating lever clevis pin and the pivot on the

flywheel housing.

11 Seats and seat belt check

1

1 Check that the seats are securely attached

to the floor crossmember and that there is no

sign of corrosion anywhere near the

mountings. Check that the seats release and

then lock in place when the release

mechanism is operated.

2 Check the seat belts for satisfactory

operation and condition. Inspect the webbing

for fraying and cuts. Check that they retract

smoothly and without binding into their reels.

3 Check the seat belt mountings, ensuring

that all the bolts are securely tightened.

12 Headlight beam alignment

check

5

Accurate adjustment of the headlight beam

is only possible using optical beam-setting

equipment, and this work should therefore be

carried out by a Rover dealer or service

station with the necessary facilities.

Basic adjustments can be carried out in an

emergency, and further details are given in

Chapter 12.

1•12 Every 3000 miles or 3 months

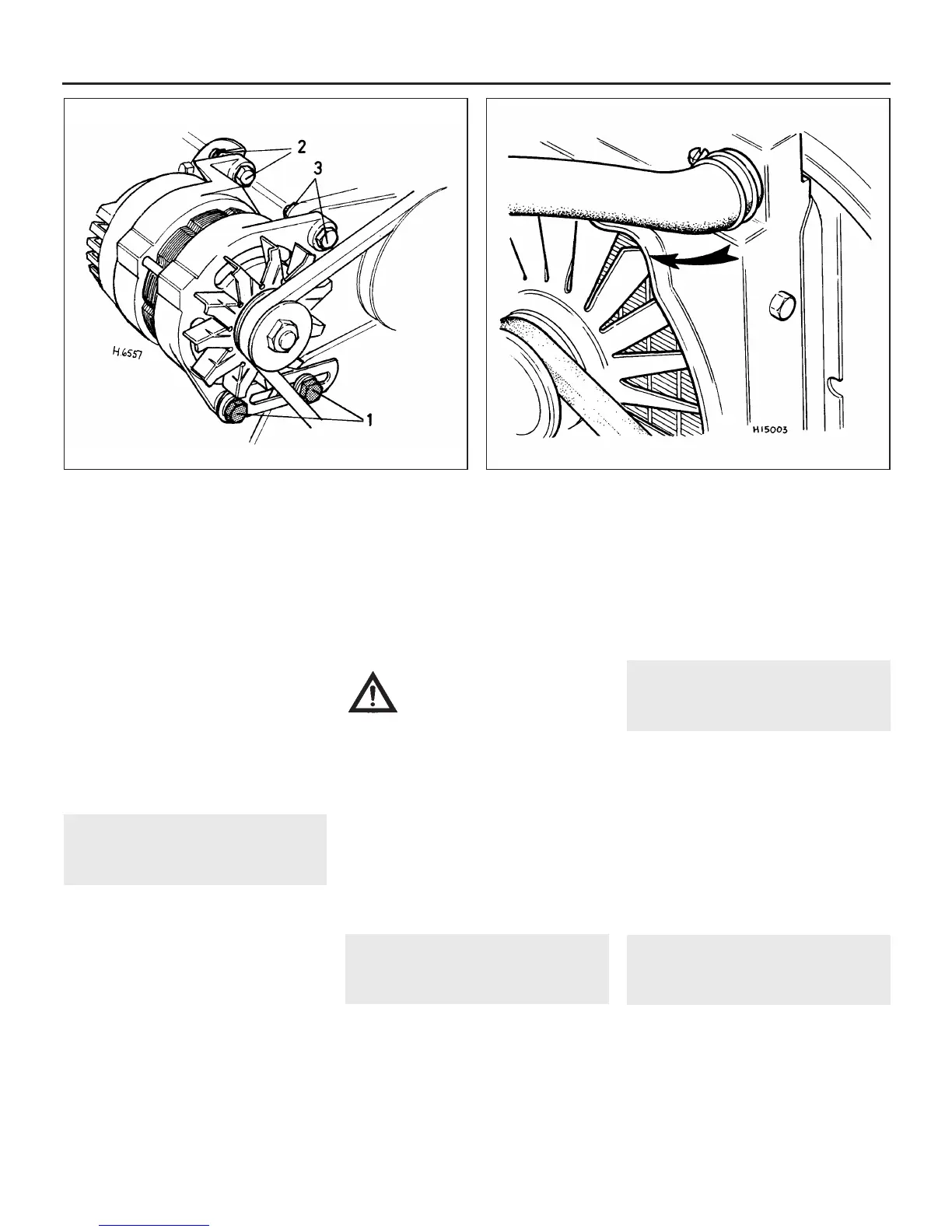

8.8b Alternator mounting and adjustment points

1 Adjustment arm fixings

2 Securing nut and bolt (rear)

3 Securing nut and bolt (front)

8.9 The gap in the radiator shroud of early models (arrowed) to

allow removal and refitting of the fan belt

Loading...

Loading...