13 Engine/transmission oil and

filter renewal

2

1 Frequent oil changes are the best

preventive maintenance the home mechanic

can give the engine, because ageing oil

becomes diluted and contaminated, which

leads to premature engine wear.

2 Make sure that you have all the necessary

tools before you begin this procedure. You

should also have plenty of rags or newspapers

handy, for mopping up any spills. The oil

should preferably be changed when the

engine is still fully warmed-up to normal

operating temperature, just after a run; warm

oil and sludge will flow out more easily. Take

care, however, not to touch the exhaust or any

other hot parts of the engine when working

under the vehicle. To avoid any possibility of

scalding, and to protect yourself from possible

skin irritants and other harmful contaminants

in used engine oils, it is advisable to wear

gloves when carrying out this work. Access to

the underside of the vehicle is greatly

improved if the vehicle can be lifted on a hoist,

driven onto ramps, or supported by axle

stands. (see “Jacking and vehicle support”).

Whichever method is chosen, make sure that

the vehicle remains level, or if it is at an angle,

that the drain point is at the lowest point.

Oil draining

3 Position the draining container under the

drain plug on the side of the transmission

casing, and unscrew the plug (see

illustration). If possible, try to keep the plug

pressed into the sump while unscrewing it by

hand the last couple of turns.

4 Allow the oil to drain into the container (see

Haynes Hint), and check the condition of the

plug’s sealing washer; renew it if worn or

damaged. Also wipe off any metal particles

that may have accumulated on the magnet.

5 Allow some time for the old oil to drain,

noting that it may be necessary to reposition

the container as the oil flow slows to a trickle;

when the oil has completely drained, wipe

clean the drain plug and its threads in the

transmission and refit the plug, tightening it to

the specified torque.

Oil filter renewal

6 The oil filter is located underneath the

dynamo or alternator on the forward-facing

side of the engine. On early manual

transmission models the filter is of the

disposable cartridge type contained within an

aluminium bowl. On later models a throwaway

canister is used. All automatic transmission

models utilise the cartridge type filter. To

renew the filter proceed as follows.

Cartridge type

7 Reposition the draining container under the

oil filter then undo and remove the long centre

bolt securing the bowl to the housing (see

illustration). On some models it may be

advantageous to remove the grille panel, as

space is rather limited.

8 With the bolts released, carefully lift away

the filter bowl, which contains the filters and

will also be full of oil.

9 Discard the old filter element but first make

sure that the metal pressure plate has not

stuck to the bottom of it. Now thoroughly

clean out the filter bowl, the bolt, and the

parts associated with it, using paraffin or a

suitable solvent (see illustration) Dry with a

lint free cloth

10 A rubber sealing ring is located in a

groove round the head of the filter housing

and forms an effective leak-proof joint

between the housing and the filter bowl. A

new rubber sealing ring is supplied with each

new filter element.

11 Carefully prise out the old sealing ring

from the locating groove. If the ring has

become hard and is difficult to move take

great care not to damage the sides of the

sealing ring groove.

12 With the old ring removed, fit the new ring

in the groove at four equidistant points and

press it home a segment at a time. Do not

insert the ring at just one point and work

round the groove pressing it home as, using

this method, it is easy to stretch the ring and

be left with a small loop of rubber which will

not fit into the locating groove (see

illustration).

13 Reassemble the oil filter assembly by first

passing up the bolt through the hole in the

bottom of the bowl, with a steel washer under

the bolt’s head and a rubber or felt washer on

top of the steel washer and next to the filter

bowl.

14 Slide the spring over the bolt followed by

the other steel washer, the remaining rubber

washer and finally the filter pressure plate

concave face downwards.

15 After fitting the new element to the bowl,

position the bowl on the rubber sealing ring

then insert and hand tighten the bolt. Before

finally tightening the centre bolt, ensure that

the lip of the filter bowl is resting squarely on

the rubber sealing ring and is not offset or

seated off the ring. If the bowl is not seating

properly, rotate it until it is. Run the engine

and check the bowl for leaks.

Every 6000 miles or 6 months 1•13

1

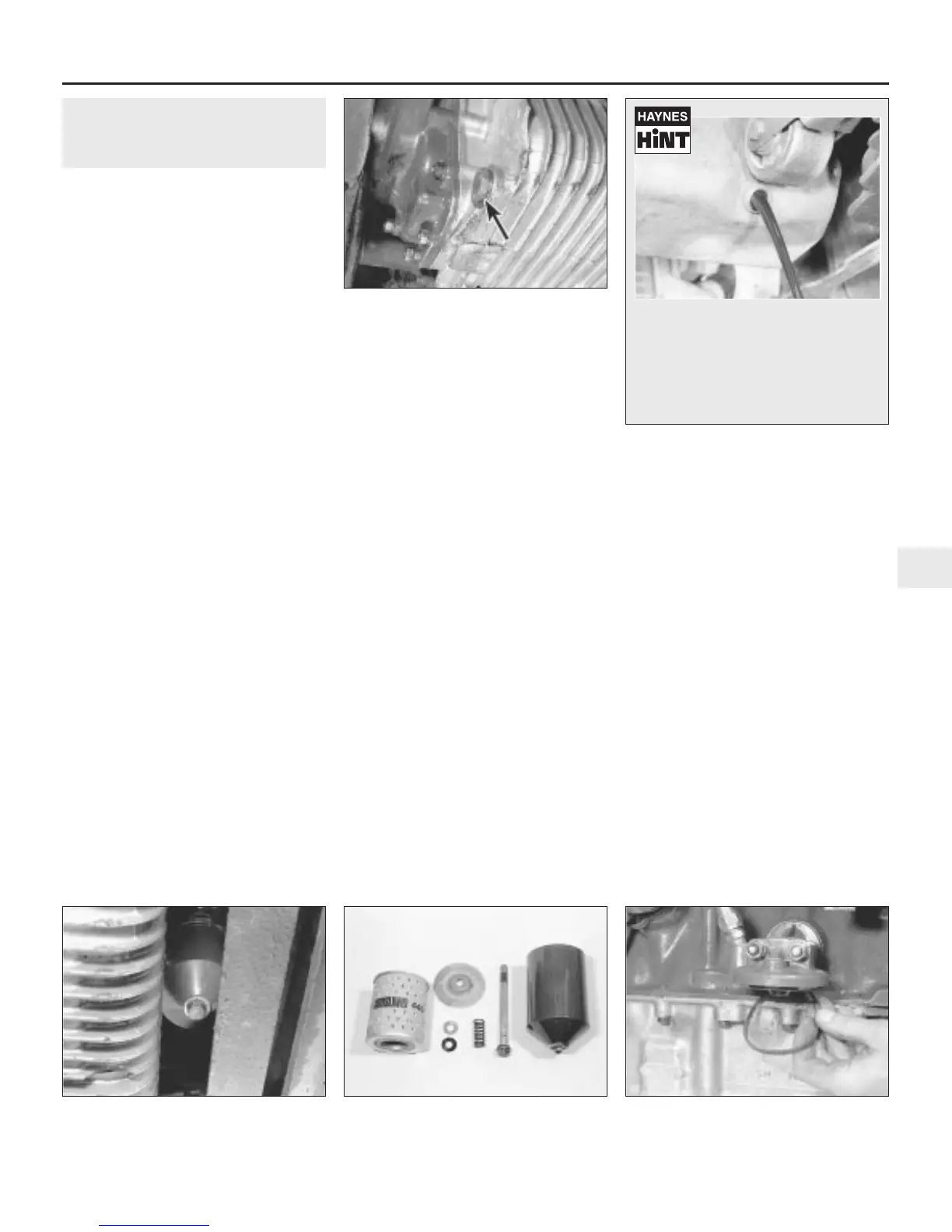

13.3 Engine/transmission oil drain plug

(arrowed)

13.7 Cartridge type oil filter and retaining

bolt as seen from below

13.12 Fitting a new cartridge type oil filter

sealing ring

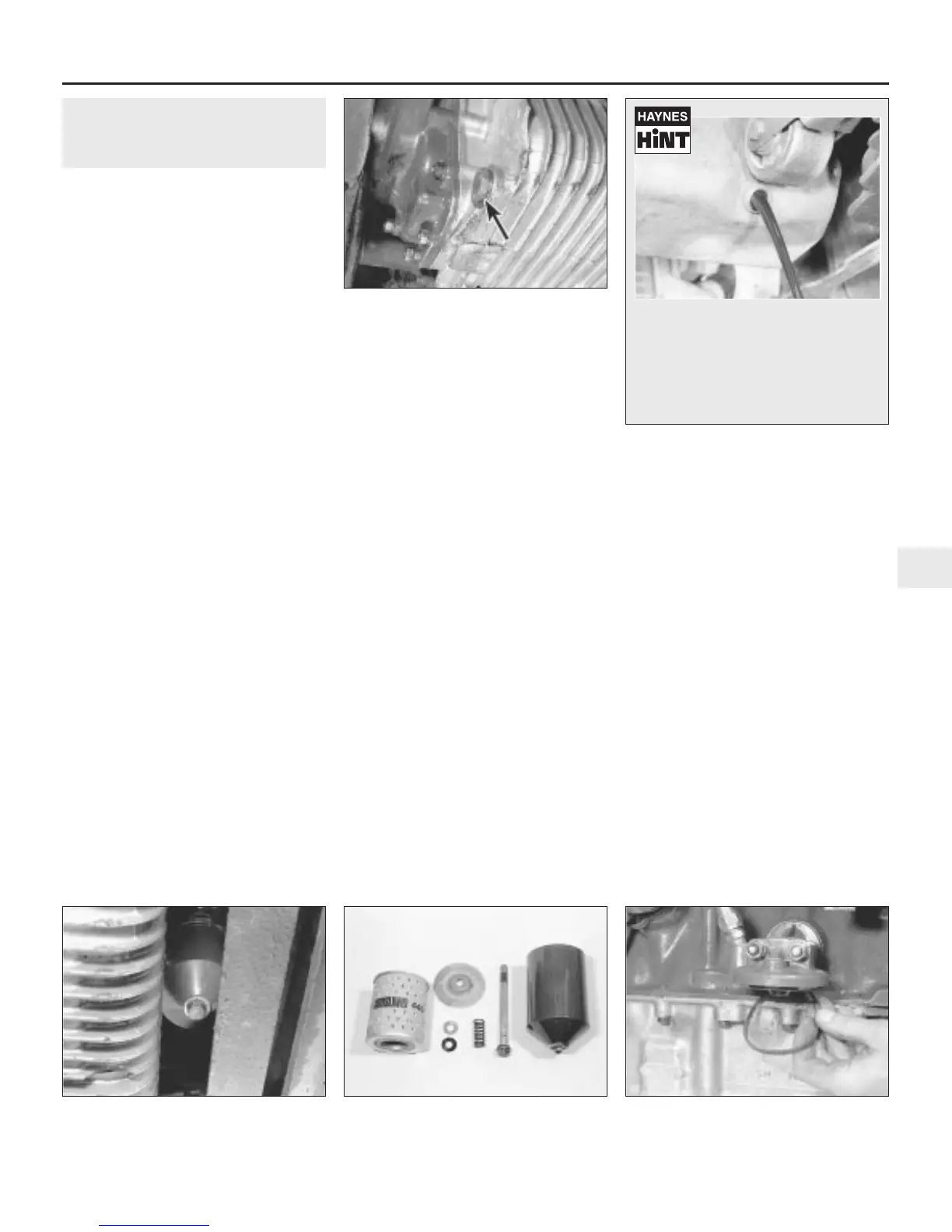

13.9 Components of the cartridge type oil

filter

Keep the drain plug pressed into the

sump while unscrewing it by hand the

last couple of turns. As the plug

releases, move it away sharply so the

stream of oil issuing from the sump

runs into the container, not up your

sleeve!

Loading...

Loading...