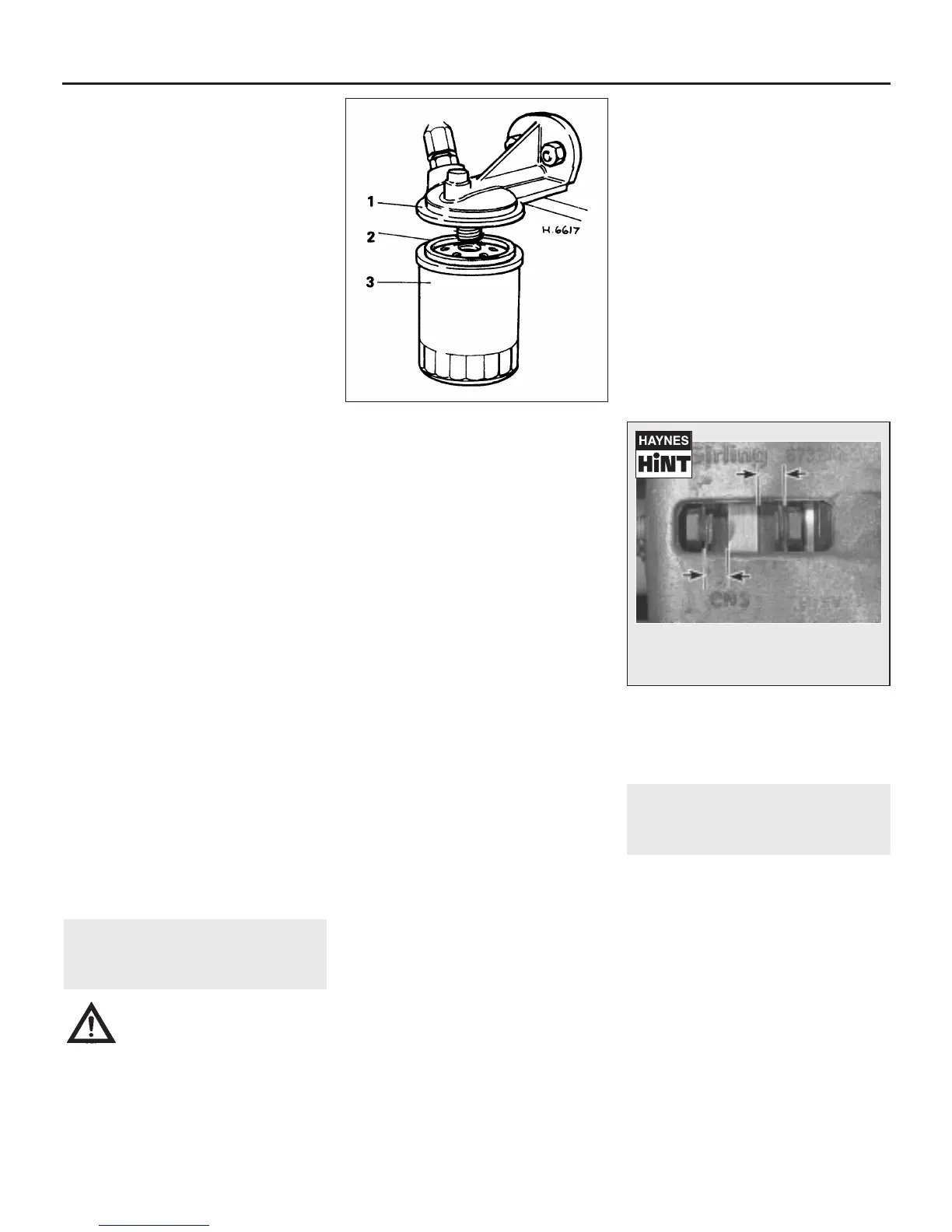

Canister type

16 Reposition the draining container under

the oil filter then, using a suitable filter removal

tool if necessary, slacken the canister initially,

then unscrew it by hand the rest of the way;

be prepared for some oil spillage (see

illustration). Empty the oil in the old canister

into the container.

17 Using a clean, lint-free rag, wipe clean the

cylinder block around the filter housing.

Check the old canister to make sure that the

rubber sealing ring hasn’t stuck to the filter

housing; if it has, carefully remove it.

18 Apply a light coating of clean engine oil to

the sealing ring on the new canister. Screw

the canister into position on the housing until

it seats, then tighten it firmly by hand only - do

not use any tools.

19 Remove the old oil and all tools from

under the vehicle, then lower the vehicle to

the ground.

Oil filling

20 Remove the dipstick and the oil filler cap

from the engine. Fill the engine with oil, using

the correct grade and type of oil, (see

Specifications). Pour in half the specified

quantity of oil first, then wait a few minutes for

the oil to fall to the transmission casing. Take

care during this operation, particularly in cold

weather as it is all to easy to fill up the rocker

cover before the oil drains down into the

engine, with very messy results as it overflows

out of the filler neck. Continue adding oil a

small quantity at a time, until the level is up to

the lower mark on the dipstick. Adding

approximately 0.5 litres will raise the level to

the upper mark on the dipstick.

21 Start the engine. The oil pressure warning

light will take a few seconds to go out while

the new filter fills with oil; do not race the

engine while the light is on. Run the engine for

a few minutes, while checking for leaks

around the oil filter seal and the drain plug.

22 Switch off the engine, and wait a few

minutes for the oil to settle in the transmission

once more. With the new oil circulated and

the filter now completely full, recheck the level

on the dipstick, and add more oil as

necessary.

23 Dispose of the used engine oil safely and

in accordance with environmental regulations

(see “General repair procedures”).

14 Front brake wear check

1

Warning: The dust created by wear

of the shoes may contain asbestos,

which is a health hazard. Never

blow it out with compressed air,

and don’t inhale any of it. An approved filtering

mask should be worn when working on the

brakes. DO NOT use petrol or petroleum-

based solvents to clean brake parts; use brake

cleaner or methylated spirit only.

Drum brake models

1 After high mileage the friction linings on the

brake shoes will have worn, and it will

therefore be necessary to fit replacement

shoes with new linings.

2 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and vehicle support”). Remove

the front roadwheels.

3 Slacken off the brake shoe adjuster(s) from

behind the backplate, and then undo and

remove the two brake drum retaining screws.

4 Remove the brake drum from the wheel

hub. If the drum is tight, gently tap its

circumference with a soft-faced mallet.

5 Brush and wipe away all traces of asbestos

dust from the brake shoes, wheel cylinders

and backplate, and also from the inner

circumference of the brake drum.

6 Inspect the friction material and renew the

brake shoes as described in Chapter 9 if they

have worn down to less than the specified

minimum thickness.

7 The brake shoes must also be renewed if

there is any sign of hydraulic fluid

contamination of the linings due to a leaking

brake wheel cylinder. If this is the case, the

cause of the leak must be traced and rectified

before fitting new brake shoes.

8 Brake shoes should always be renewed as

complete sets (four shoes to a set), otherwise

uneven braking and pulling to one side may

occur.

9 It is advisable to check that the brake wheel

cylinders are operating correctly before

proceeding further. To do this hold the brake

shoes in position using two screwdrivers while

an assistant very slowly depresses the brake

pedal slightly. Check that the wheel cylinder

pistons move out as the pedal is depressed,

and return when the pedal is released. If this is

not the case, it is quite likely that one of the

wheel cylinder pistons is seized and the cylinder

should therefore be renewed (Chapter 9).

10 Also check the condition of the brake

drum, If it is deeply scored on its inner

circumference it may be possible to have it

skimmed at an engineering works. If the

scoring is severe, renewal will be necessary

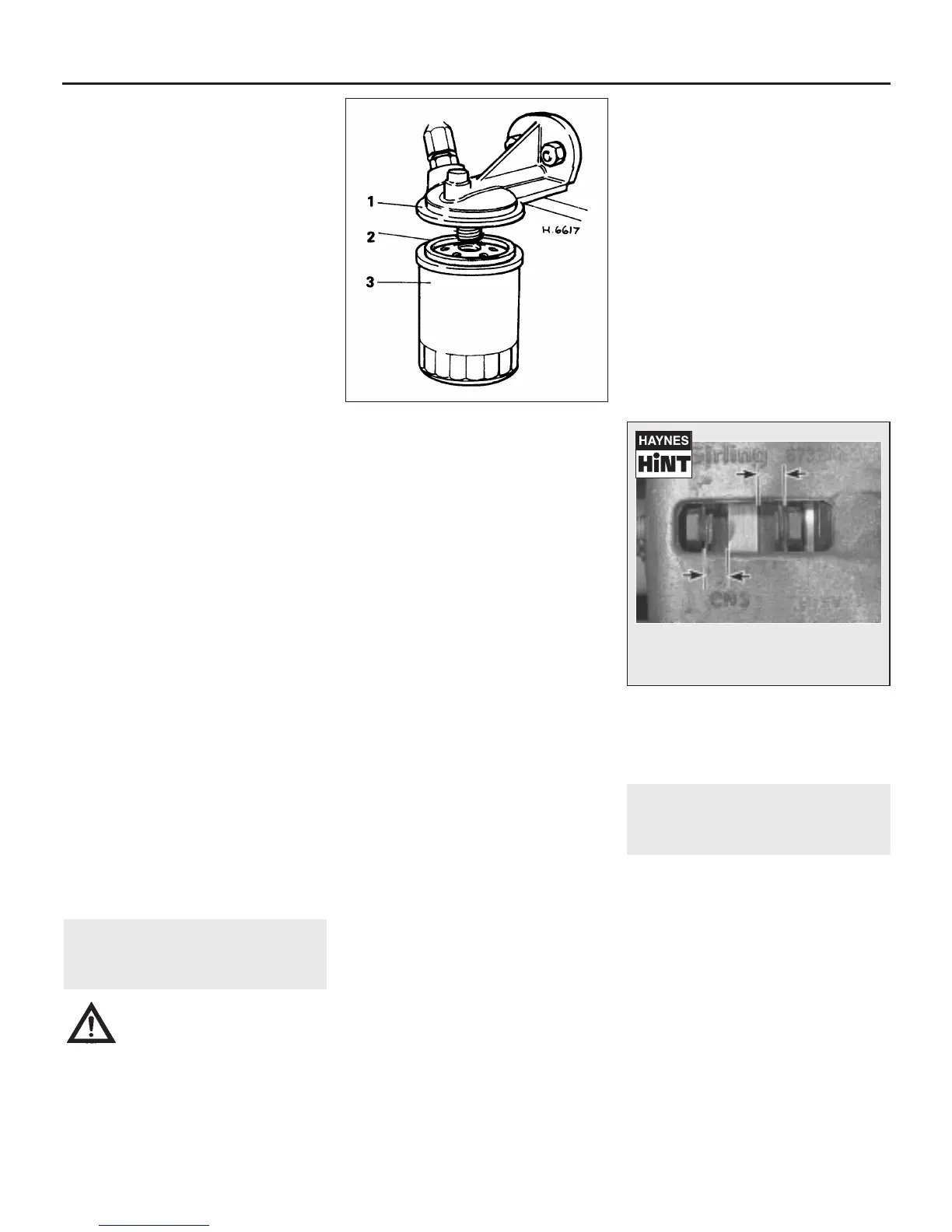

Disc brake models

11 Jack up the front or rear of the vehicle in

turn, and support it on axle stands (see

“Jacking and vehicle support”).

12 For better access to the brake calipers,

remove the roadwheels.

13 Look through the opening in the front of

the caliper, and check that the thickness of

the friction lining material on each of the pads

is not less than the recommended minimum

thickness given in the Specifications (see

Haynes Hint). If any one of the brake pads

has worn down to, or below, the specified

limit, all four pads must be renewed as a set

(ie all the front pads).

14 For a comprehensive check, the brake

pads should be removed and cleaned. The

operation of the brake calipers can then be

checked, and the brake discs can be fully

examined. Refer to Chapter 9 for details.

15 Driveshaft gaiter check

1

With the vehicle raised and securely

supported on stands (see “Jacking and

vehicle support”), turn the steering onto full

lock, then slowly rotate the roadwheel.

Inspect the condition of the outer constant

velocity (CV) joint rubber gaiters, squeezing

the gaiters to open out the folds. Check for

signs of cracking, splits or deterioration of the

rubber, which may allow the grease to

escape, and lead to water and grit entry into

the joint. Also check the security and

condition of the retaining clips. Repeat these

checks on the inner CV joints where offset

sphere type joints are fitted. If any damage or

deterioration is found, the gaiters should be

renewed as described in Chapter 8.

At the same time, check the general condition

of the CV joints themselves by first holding the

1•14 Every 6000 miles or 6 months

13.16 Canister type oil filter

1 Housing

2 Sealing ring

3 Filter

Look through the opening in the caliper

and check the thickness of the friction

lining material on the brake pads

Loading...

Loading...