driveshaft and attempting to rotate the wheel.

Repeat this check by holding the inner joint and

attempting to rotate the driveshaft. Any

appreciable movement indicates wear in the

joints, wear in the driveshaft splines, or a loose

driveshaft retaining nut.

16 Steering and suspension

lubrication

1

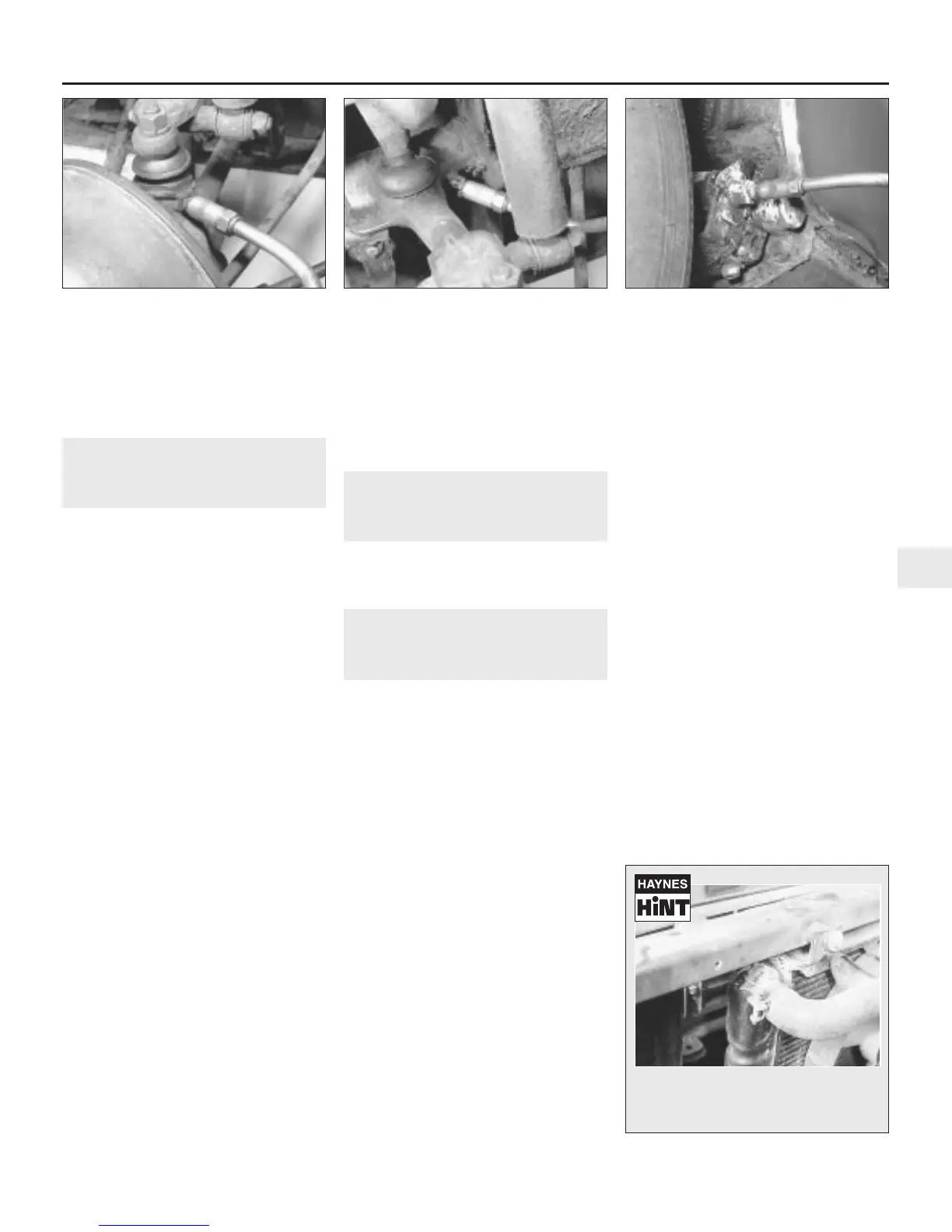

1 Unlike most modern cars, there are a number

of steering and suspension joints on the Mini

which require regular attention. Provision for

lubrication of these joints is by means of a

grease nipple, to which a grease gun can be

engaged. The grease nipples are located in the

following areas (see illustrations):

a) Steering swivel hub; two nipples, one

upper and one lower on each side.

b) Upper suspension arm inner pivot; one

nipple on each arm.

c) Rear radius arm pivot; one nipple on each

pivot. Remove the rubber blanking plug to

expose the nipple on early models.

2 When lubricating the front grease nipples it

is preferable to raise the front of the car and

support it on axle stands (see “Jacking and

vehicle support”) so that the load is taken off

the suspension. This will allow the grease to

penetrate into the joints more effectively. The

rear radius arm pivots can be lubricated with

the car on its roadwheels if wished.

3 With the car raised and suitably supported,

wipe clean the area all round the grease

nipple and the nipple itself. Engage the head

of a grease gun, filled with the specified

grease, squarely onto the nipple, keeping it

pushed fully home. Operate the gun until

grease can be seen to appear from under the

dust cover over the joint or from around the

side of the pivot bushes.

4 When lubricating the rear radius arm pivots, a

generous amount of grease will be needed each

side, quite a bit more than was required for the

front suspension joints. It probably won’t be

possible to tell when sufficient has been

applied, unless you look underneath at the inner

attachment on the subframe, it may be possible

to see it appear around the inner pivot; add a bit

more if in doubt .This is a vitally important area

on the Mini and it must be well lubricated.

5 Although not actually part of the steering

and suspension, the handbrake cable guides

and the moving sectors on the rear subframe

should be lubricated at this time to ensure

smooth operation. There are no grease

nipples, so the grease should be applied with

a wooden spatula or similar tool to lubricate

these areas thoroughly.

17 Rear brake wear check

1

The procedure for checking the rear brake

components is the same as described in

Section 14 for models with drum brakes.

18 Underbonnet check for fluid

leaks and hose condition

1

General

1 High temperatures in the engine

compartment can cause the deterioration of

the rubber and plastic hoses used for engine,

accessory and emission systems operation.

Periodic inspection should be made for

cracks, loose clamps, material hardening and

leaks.

2 Carefully check the large top and bottom

radiator hoses, along with the other smaller-

diameter cooling system hoses and metal

pipes; do not forget the heater hoses/pipes

which run from the engine to the bulkhead.

Inspect each hose along its entire length,

replacing any that are cracked, swollen or

shows signs of deterioration. Cracks may

become more apparent if the hose is

squeezed (see Haynes Hint).

3 Make sure that all hose connections are

tight. If the spring clamps that are used to

secure some of the hoses appear to be

slackening, they should be renewed to

prevent the possibility of leaks.

4 Some other hoses are secured to their

fittings with screw type clips. Where screw

type clips are used, check to be sure they

haven’t slackened, allowing the hose to leak.

If clamps or screw type clips aren’t used,

make sure the hose has not expanded and/or

hardened where it slips over the fitting,

allowing it to leak.

5 Check all fluid reservoirs, filler caps, drain

plugs and fittings etc, looking for any signs of

leakage of oil, transmission and/or brake

hydraulic fluid or coolant. If the vehicle is

regularly parked in the same place, close

inspection of the ground underneath it will

soon show any leaks. As soon as a leak is

detected, its source must be traced and

rectified. Where oil has been leaking for some

time, it is usually necessary to use a steam

cleaner, pressure washer or similar, to clean

away the accumulated dirt, so that the exact

source of the leak can be identified.

Vacuum hoses

6 It’s quite common for vacuum hoses,

especially those in the emissions system, to

be numbered or colour-coded, or to be

identified by coloured stripes moulded into

them. Various systems require hoses with

different wall thicknesses, collapse resistance

and temperature resistance. When renewing

hoses, be sure the new ones are made of the

same material.

7 Often the only effective way to check a

hose is to remove it completely from the

vehicle. If more than one hose is removed, be

sure to label the hoses and fittings to ensure

correct installation.

8 When checking vacuum hoses, be sure to

include any plastic T-fittings in the check.

Every 6000 miles or 6 months 1•15

1

16.1a Lubricating the swivel hub upper

grease nipple . . .

16.1b . . . the upper suspension arm inner

pivot grease nipple . . .

16.1c . . . and the rear radius arm pivot

grease nipple

A leak in the cooling system will usually

show up as white or rust coloured

deposits on the area adjoining the leak

Loading...

Loading...