Inspect the fittings for cracks, and check the

hose where it fits over the fitting for distortion,

which could cause leakage.

9 A small piece of vacuum hose can be used

as a stethoscope to detect vacuum leaks.

Hold one end of the hose to your ear, and

probe around vacuum hoses and fittings,

listening for the “hissing” sound characteristic

of a vacuum leak.

Warning: When probing with the

vacuum hose stethoscope, be

very careful not to come into

contact with moving engine

components such as the fan or fan belt.

Fuel hoses

Warning: Before carrying out the

following operation, refer to the

precautions given in “Safety

first!” at the beginning of this

manual, and follow them implicitly. Petrol

is a highly dangerous and volatile liquid,

and the precautions necessary when

handling it cannot be overstressed.

10 Check all fuel hoses for deterioration and

chafing. Check especially for cracks in areas

where the hose bends, and also just before

fittings, such as where a hose attaches to the

carburettor.

11 Spring-type clamps are commonly used

on fuel lines. These clamps often lose their

tension over a period of time, and can be

“sprung” during removal. Replace all spring-

type clamps with screw clips whenever a hose

is replaced.

Metal lines

12 Sections of metal piping are often used

for fuel line between the fuel tank, filter and

the engine. Check carefully to be sure the

piping has not been bent or crimped, and that

cracks have not started in the line.

13 If a section of metal fuel line must be

renewed, only seamless steel piping should

be used, since copper and aluminium piping

don’t have the strength necessary to

withstand normal engine vibration.

14 Check the metal brake lines where they

enter the master cylinder for cracks in the

lines or loose fittings. Any sign of brake fluid

leakage calls for an immediate and thorough

inspection of the brake system.

19 Fuel system components,

checks and lubrication

1

1 Sparingly apply a few drops of light oil to the

throttle spindles, accelerator cable and the

pedal pivot. Similarly lubricate the exposed

ends of the choke cable (where fitted).

2 Check that there is a small amount of

slackness in the cable so that the throttle linkage

closes fully with the accelerator pedal released.

Also check that full throttle can be obtained with

the accelerator pedal fully depressed.

3 If there is any doubt about the cable

adjustment, refer to the relevant Parts of

Chapter 4 for the full adjustment procedure.

4 On carburettor models, unscrew the piston

damper cap from the top of the carburettor

dashpot (see illustration). Top up the damper

with engine oil until the level is 13.0 mm above

the top of the hollow piston rod.

5 Slowly push the damper back into the

piston and screw on the cap taking care not

to cross-thread it.

20 Contact breaker points

check and adjustment

3

Refer to Chapter 5B.

21 Distributor lubrication

1

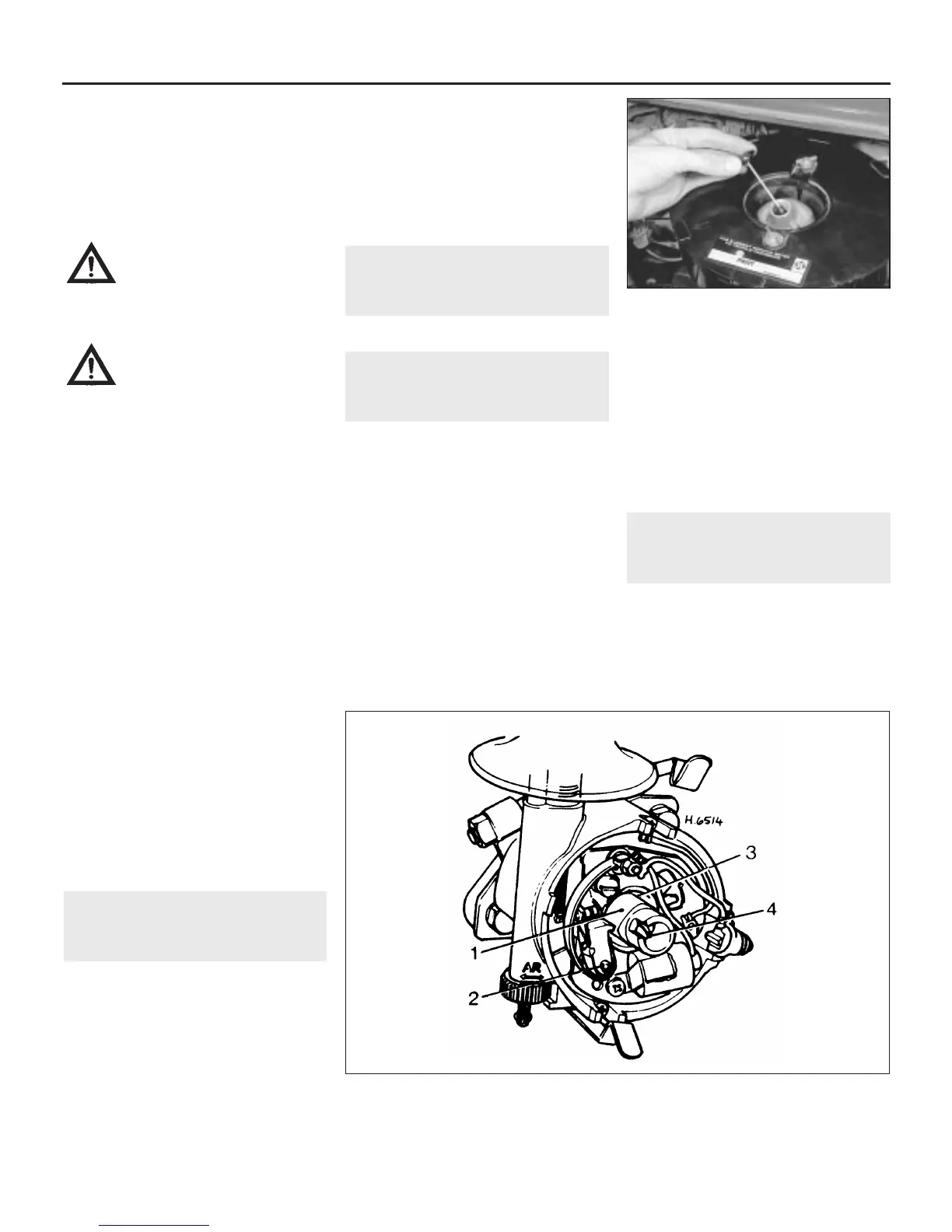

1 It is important that the distributor cam is

lightly lubricated with general purpose grease,

and that the contact breaker arm, centrifugal

advance weights and cam spindle are also

very lightly lubricated.

2 Great care should be taken not to use too

much lubricant, as any excess that might find

its way onto the contact breaker points could

cause burning and misfiring.

3 If an ignition shield is fitted over the front of

the engine, release the three plastic retaining

lugs and lift away the shield. Detach the two

spring clips or undo the two screws securing

the distributor cap to the distributor body and

lift off the cap.

4 To gain access to the cam spindle, lift away

the rotor arm. Drop no more than two drops of

engine oil onto the felt pad or screw head (see

illustration). This will run down the spindle

when the engine is hot and lubricate the

bearings. The centrifugal advance weights

can be lubricated by dropping two or three

drops of engine oil through one of the holes or

slots in the distributor baseplate. No more

than one drop of oil should be applied to the

contact breaker arm pivot post.

5 Refit the rotor arm, distributor cap and

ignition shield on completion.

22 Clutch return stop

adjustment

1

Note: As friction linings of the clutch disc wear,

the distance between the clutch release bearing

and the clutch thrust plate will decrease. The

pressure plate will then move in closer to the

clutch disc to compensate for wear. Unless the

wear is taken up by adjustment of the stop

located between the flywheel housing and the

1•16 Every 6000 miles or 6 months

19.4 Top up the piston damper on

carburettor models

21.4 Distributor lubrication points

1 Contact breaker cam

2 Contact breaker pivot post

3 Centrifugal weights lubrication point

4 Cam spindle

Loading...

Loading...