operating lever, the clutch will start to slip. On

later models fitted with the verto type clutch, the

assembly is self-adjusting and the following

procedure will not be necessary.

1 To carry out the adjustment, first disconnect

the clutch operating lever return spring.

2 Pull the operating lever away from the

engine until all the free play is eliminated.

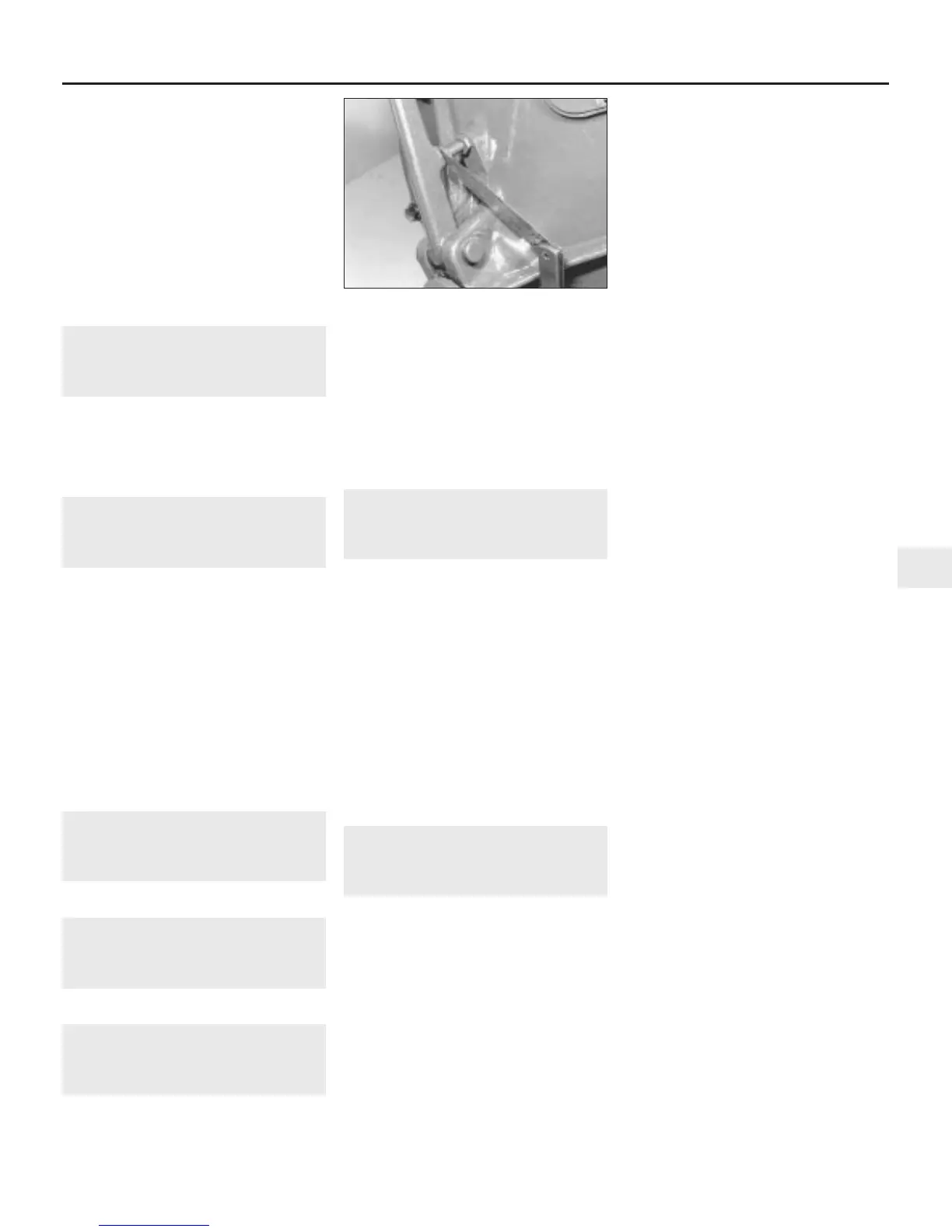

3 Hold the lever in this position and measure

the gap between the lever and the head of the

stop using feeler blades (see illustration).

4 If necessary, slacken the locknut and adjust

the stop bolt until the specified gap is

achieved. Then tighten the locknut.

23 Dynamo check and

lubrication

1

Dynamo checks and lubrication consist

simply of checking the fan belt condition and

tension (Section 8) and adding a few drops of

engine oil to the dynamo rear bearing

lubricating hole.

24 Control box cleaning and

inspection

1

On dynamo equipped models, remove the

control box cover and check the cut-out and

regulator contacts. If they are dirty or rough or

burnt, place a piece of fine glasspaper (do not

use emery paper or carborundum paper)

between the cut-out contacts, close them

manually, and draw the glasspaper through

several times.

Clean the regulator contacts in exactly the

same way, but use emery or carborundum

paper and not glasspaper. Carefully clean

both sets of contacts from all traces of dust

with a rag moistened in methylated spirit. Refit

the cover on completion.

25 Ignition timing check and

adjustment

3

Refer to Chapter 5B.

26 Carburettor idle speed and

mixture adjustment

3

Refer to Chapter 4A.

27 Door, boot and bonnet

check and lubrication

1

1 Check that the doors, bonnet and boot lid

close securely. Check that the bonnet safety

catch operates correctly. Check the operation

of the door check straps.

2 Lubricate the hinges, door check straps,

the striker plates and the bonnet catch

sparingly with a little oil or grease.

3 If any of the doors, bonnet or boot lid do not

close effectively or appear not to be flush with

the surrounding panels, carry out the adjustment

procedures contained in Chapter 11.

28 Bodywork, paint and exterior

trim check

1

1 The best time to carry out this check is after

the car has been washed so that any surface

blemish or scratch will be clearly evident and

not hidden by a film of dirt.

2 Starting at one front corner check the

paintwork all around the car, looking for minor

scratches or more serious dents. Check all

the trim and make sure that it is securely

attached over its entire length.

3 Check the security of all door locks, door

mirrors, badges, bumpers, front grille and

wheel trim. Anything found loose, or in need of

further attention should be done with reference

to the relevant Chapters of this manual.

4 Rectify any problems noticed with the

paintwork or body panels (see Chapter 11).

29 Road test

1

Check the operation and

performance of the braking

system

1 Make sure that the vehicle does not pull to

one side when braking, and that the wheels

do not lock when braking hard.

2 Check that there is no vibration through the

steering when braking.

3 Check that the handbrake operates

correctly, without excessive movement of the

lever, and that it holds the vehicle stationary

on a slope.

4 With the engine switched off, test the

operation of the brake servo unit (where fitted)

as follows. Depress the footbrake four or five

times to exhaust the vacuum, then start the

engine. As the engine starts, there should be a

noticeable “give” in the brake pedal as vacuum

builds up. Allow the engine to run for at least

two minutes, and then switch it off. If the brake

pedal is now depressed again, it should be

possible to detect a hiss from the servo as the

pedal is depressed. After about four or five

applications, no further hissing should be heard,

and the pedal should feel considerably harder.

Steering and suspension

5 Check for any abnormalities in the steering,

suspension, handling or road “feel”.

6 Drive the vehicle, and check that there are

no unusual vibrations or noises.

7 Check that the steering feels positive, with

no excessive sloppiness or roughness, and

check for any suspension noises when

cornering and driving over bumps.

Drivetrain

8 Check the performance of the engine,

transmission and driveline.

9 Check that the engine starts correctly, both

when cold and when hot.

10 Listen for any unusual noises from the

engine and transmission.

11 Make sure that the engine runs smoothly

when idling, and that there is no hesitation

when accelerating.

12 On manual transmission models, check

that all gears can be engaged smoothly

without noise, and that the gear lever action is

not abnormally vague or “notchy”.

13 On automatic transmission models, make

sure that the drive seems smooth without

jerks or engine speed “flare-ups”. Check that

all the gear positions can be selected with the

vehicle at rest.

Clutch

14 Check that the clutch pedal moves

smoothly and easily through its full travel, and

that the clutch itself functions correctly, with

no trace of slip or drag. If the movement is

uneven or stiff in places, check the system

components with reference to Chapter 6.

Instruments and electrical

equipment

15 Check the operation of all instruments

and electrical equipment.

16 Make sure that all instruments read

correctly, and switch on all electrical

equipment in turn, to check that it functions

properly.

17 Test the operation of the brake failure

warning system (where fitted) by pressing the

test switch located next to the heated rear

window switch. When pressed, the switch

should light and go out when released.

18 If the light should come on when driving,

the brake fluid level should be checked (and

topped up, if necessary), as soon as possible.

Every 6000 miles or 6 months 1•17

1

22.3 Using feeler blades to measure the

clutch return stop clearance

Loading...

Loading...