Pomona, CA Clemmons, NC Nashville, TN

Tel: 908-355-7995 www.hayward-pool.com

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

39

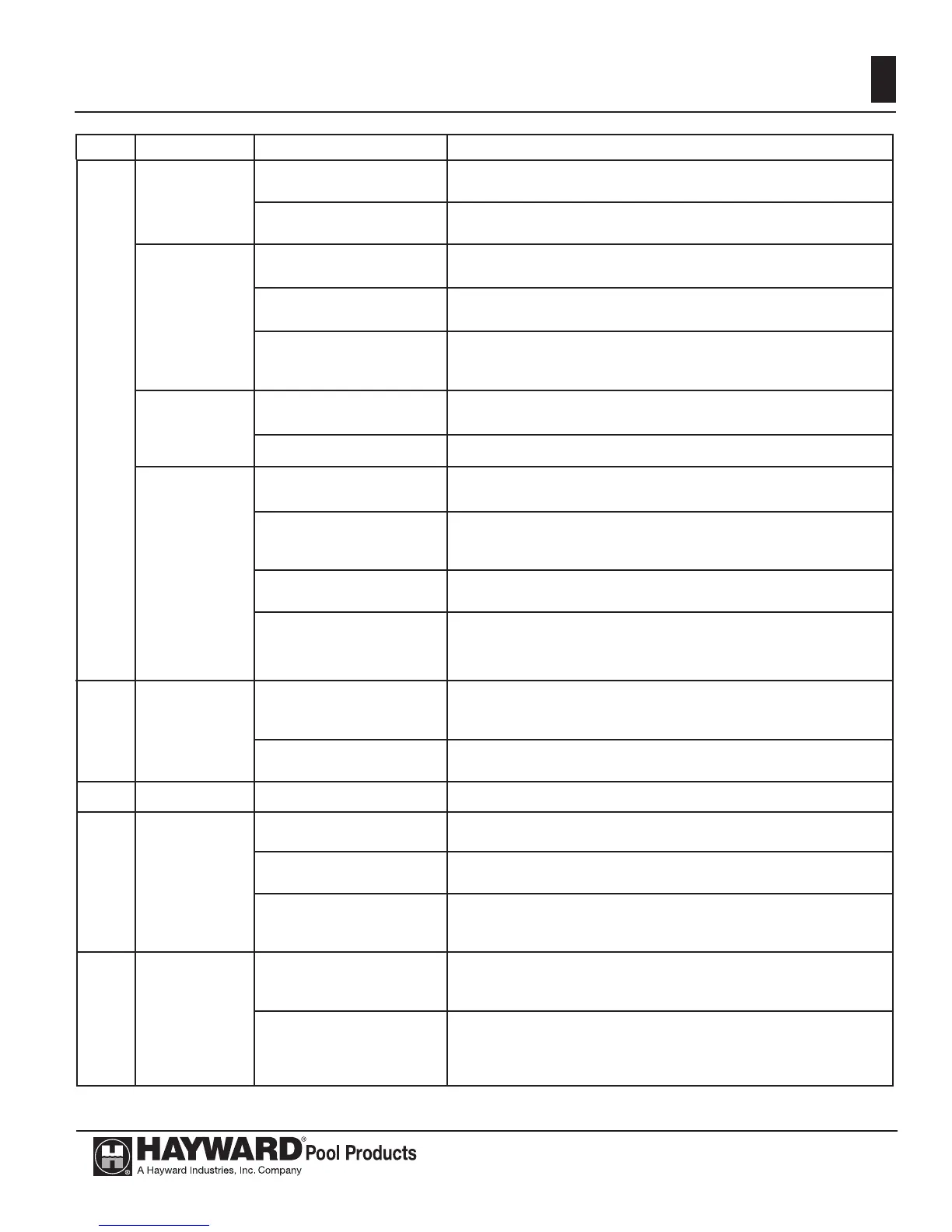

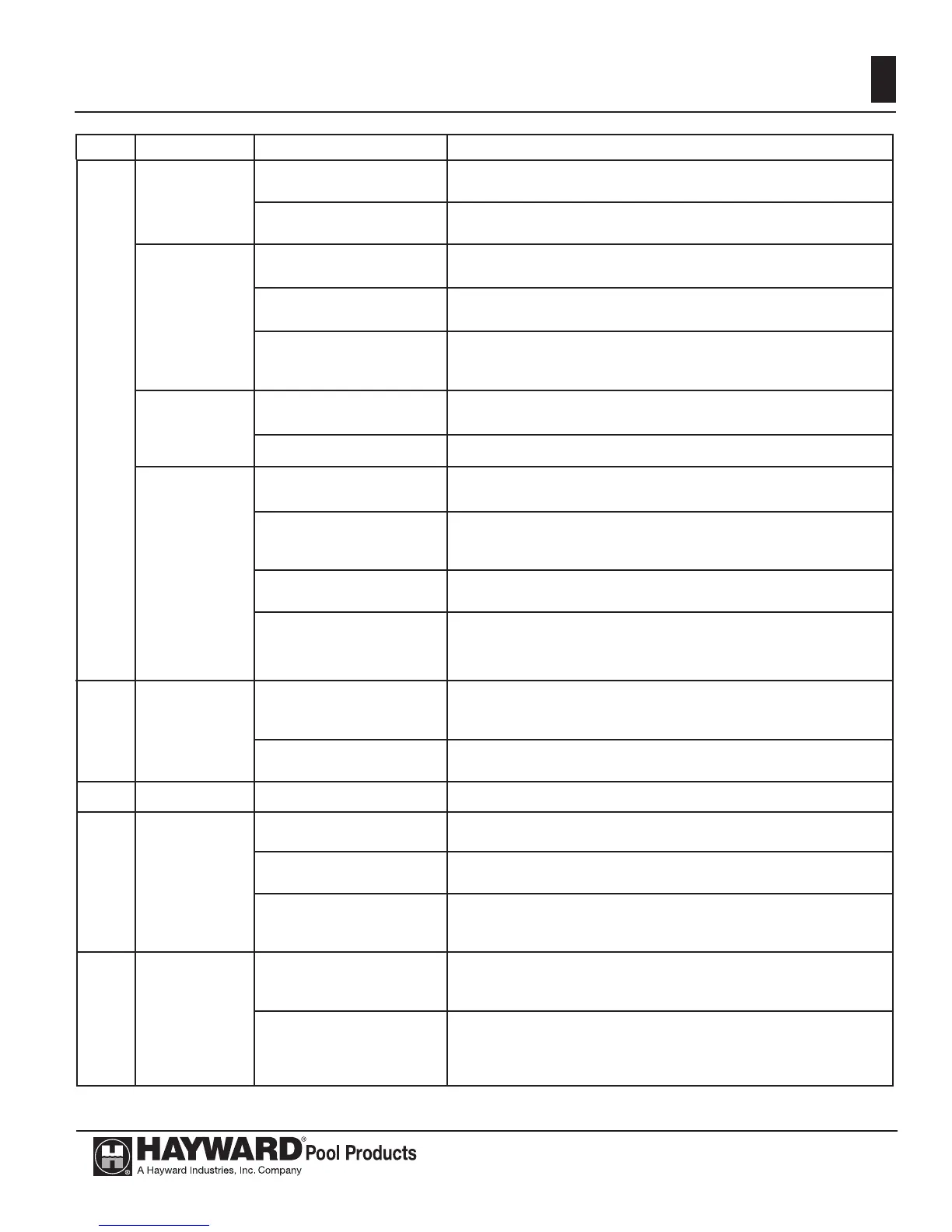

Figure 22: TROUBLESHOOTING

Code Fault Diagnosis Step Remedy

None

Heater will not

power up

1. Ensure fi eld power supply

to heater is turned on.

Measure for fi eld supply voltage across primary terminals of

transformer.

2. Check for defective

Transformer.

If 120 VAC is present at transformer primary, check secondary for 24

VAC. If not present, replace transformer.

Low voltage

circuit fault.

1. Check for faulty Control

Module wiring.

Inspect Control Module wiring. Ensure all plugs are securly fastened

to Control Module. If OK, proceed to step 2.

2. Verify low voltage input

to Control Module.

Verify 24VAC across R and C terminals on Control Module. If not

OK, replace harness. If OK, procced to step 3.

3. Verify that F1 Fuse on

Control Board is not open.

Remove F1 fuse from fuseholder. Measure continuity across fuse.

If OK, replace Control Module. If fuse is open, proceed to section

titled ‘‘Open Fuse on ignition board’’.

Low voltage

fault

1. Check for faulty

Transformer wiring.

Inspect Transformer wiring. Ensure insulation on wiring is not worn.

If OK, proceed to step 2.

2. Defective Transformer

Replace Transformer.

Open Fuse on

ignition board

1. Check for faulty Gas

Valve wiring.

Inspect Gas Valve wiring. Ensure insulation on wiring is not worn.

If OK, proceed to step 2.

2. Verify that Gas Valve is

not defective.

Measure for resistance across Gas Valve terminals and between each

terminal and ground. If short exists, replace Gas Valve. If OK,

proceed to step 3.

3. Check for faulty Control

Module wiring.

Inspect Control Module wiring. Ensure insulation on wiring is not

worn. If OK proceed to step 4.

4. Control Module is

defective.

Replace Control Module.

bD

Bad Board or

Secondary High

Vo l tage Fault

1. Check for defective

Harness.

Disconnect plug from E10 connector of Contol Module. Measure

for 120VAC across pins 1 and 3 of Plug on Harness. If OK, replace

Control Module. If not OK, replace Harness.

2. Check for defective

Transformer.

If 120 VAC is present at transformer primary, check secondary for 24

VAC. If not present, replace transformer.

EE

Bad Board 1. Defective Control Module

Replace Control Module.

CE

Communicat-

ion Error

between

Control Module

and Display

Interface

Assembly

1. Disconnect and then re-

connect power to heater.

2. Check for faulty wiring or

connection.

Inspect Display Interface Wiring. Ensure Display Interface Plug is

securely attached to Control Module. If OK, proceed to step 3.

3. Control Module and/or

Display Interface Assembly

are defective.

Replace Control Module and/or Display Interface Assembly.

PF

Supply power

fault

1.Check polarity of electrical

outlet powering the heater.

If neutral and line voltage wires are reversed on the electrical outlet,

have an electrician remedy this issue. (Swap the line and neutral

wires.) If line and neutral wires are correct, proceed to step 2.

2. Check that the ground

wire is connected in the

electrical outlet powering

the heater.

If ground wire is not connected, have an electrician remedy this

issue. If ground wire is conected, proceed to step 3.

Loading...

Loading...