The synchromesh mechanism consists primarily of synchromesh cones, block

rings and inserts.

(1) Synchromesh cone

The gear (11) or (13) has a male cone, i.e. synchromesh cone mating with the

block ring (2) through respective cone friction surface, and an involute spline (3)

engaged with mesh sleeve spline (6).

(2) Block ring

The block ring has a female cone friction surface mating with the male cone’s of

the synchromesh cone and three notches on its circumference to align the spline of

mesh sleeve with block ring’s so that the mesh sleeve spline (6) is to be pressed

toward the block ring spline (1).

(3) Inserter

There are three inserters included. Their center projections are fitted in the inner

annular groove of the mesh sleeve spline, respective two ends in three notches of the

block ring. These inserters are pressed against the top of mesh sleeve spline by two

springs (8) to keep the block ring in position.

The operation of synchromesh mechanism is completed in six steps below (take

the gear (11) for example).

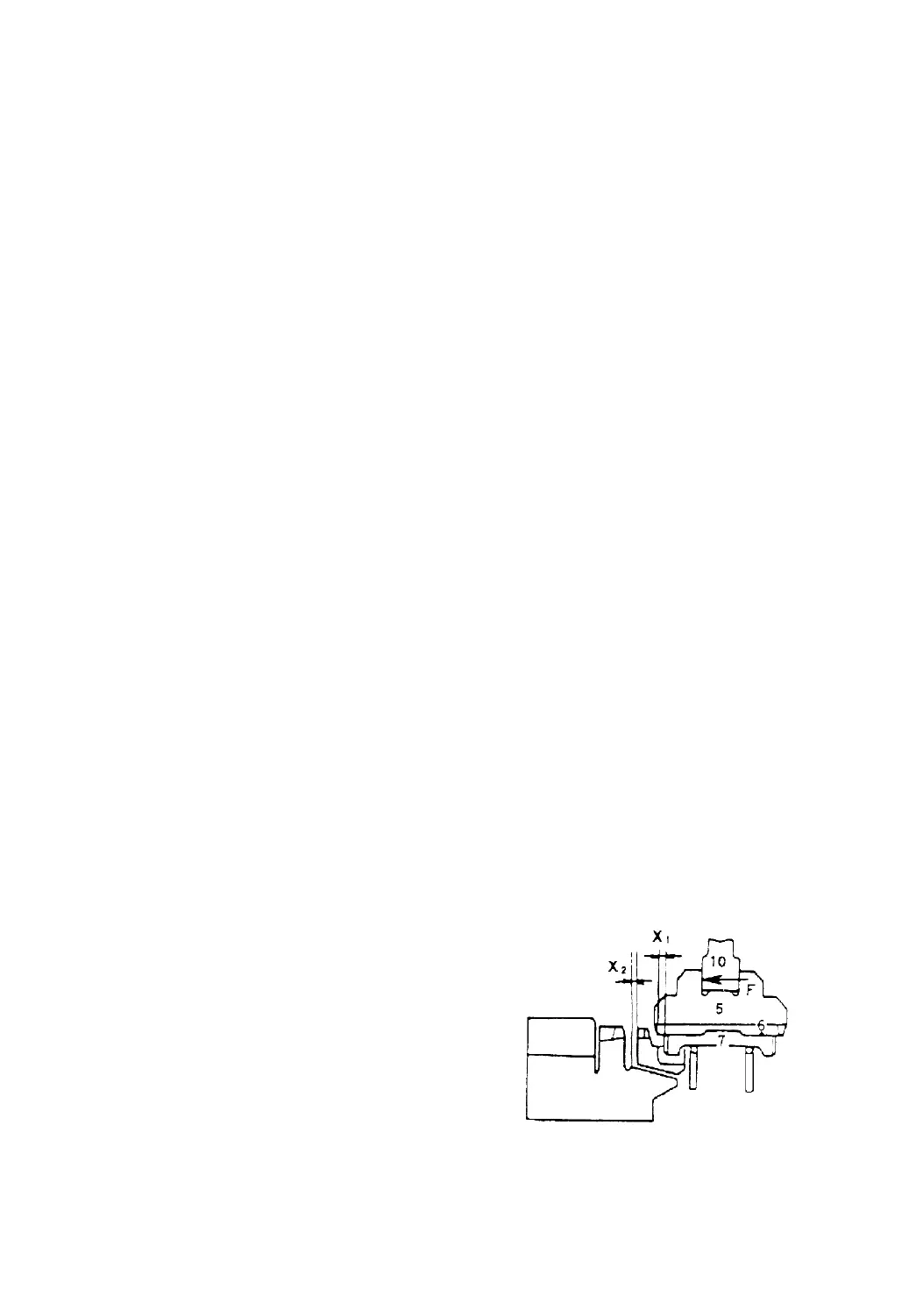

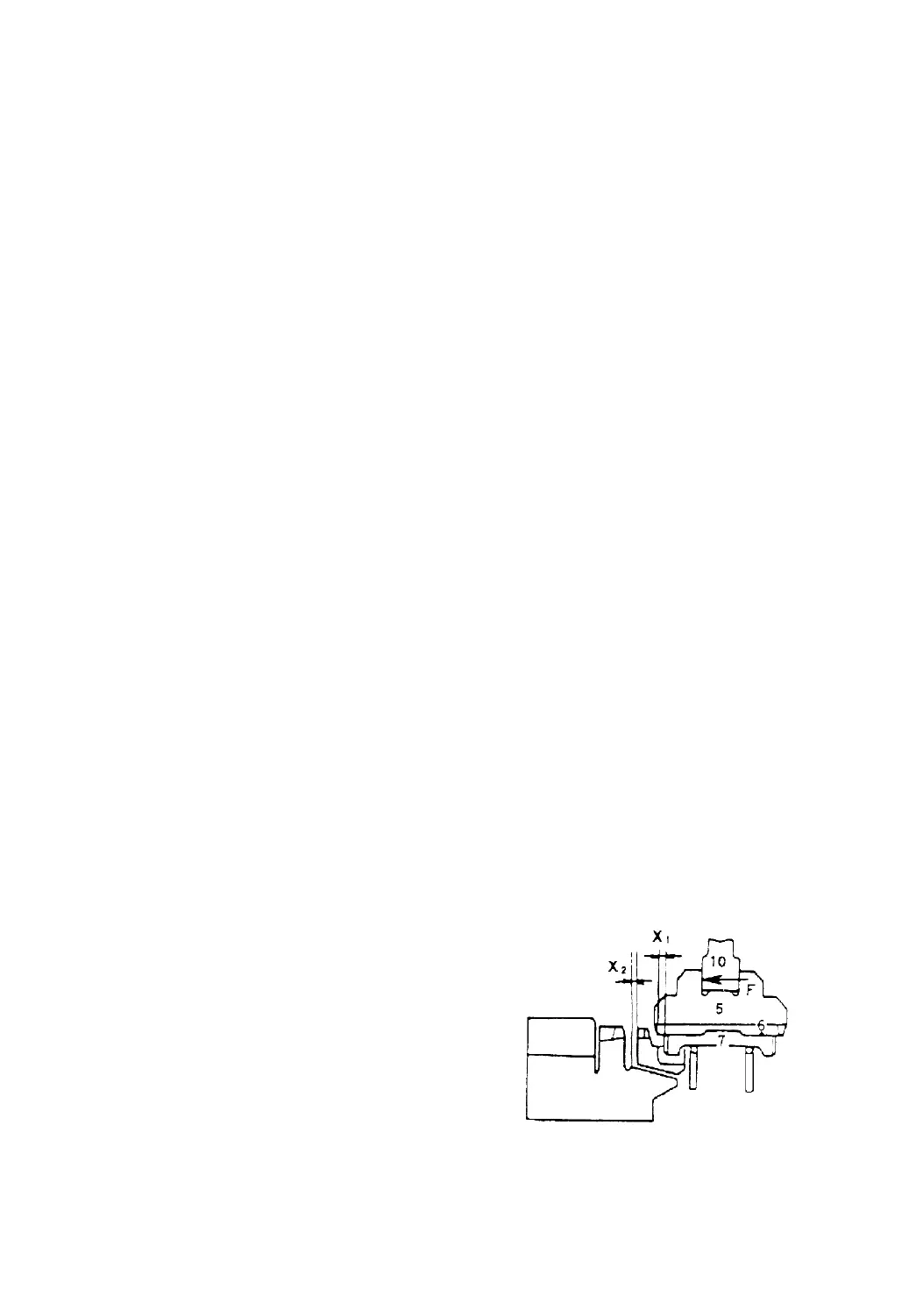

1st Step (See Fig.3-4)

When the force is applied on the shift

lever, it is transmitted to the mesh sleeve (5)

through the shift fork and then makes the

mesh sleeve (5) and inserters (7) axially move

toward the gear (11) by X and X

1 2

respectively. In this time, the center

projections of inserters (7) are still in the

groove of mesh sleeve spline.

Fig. 3-4

-21-

Loading...

Loading...