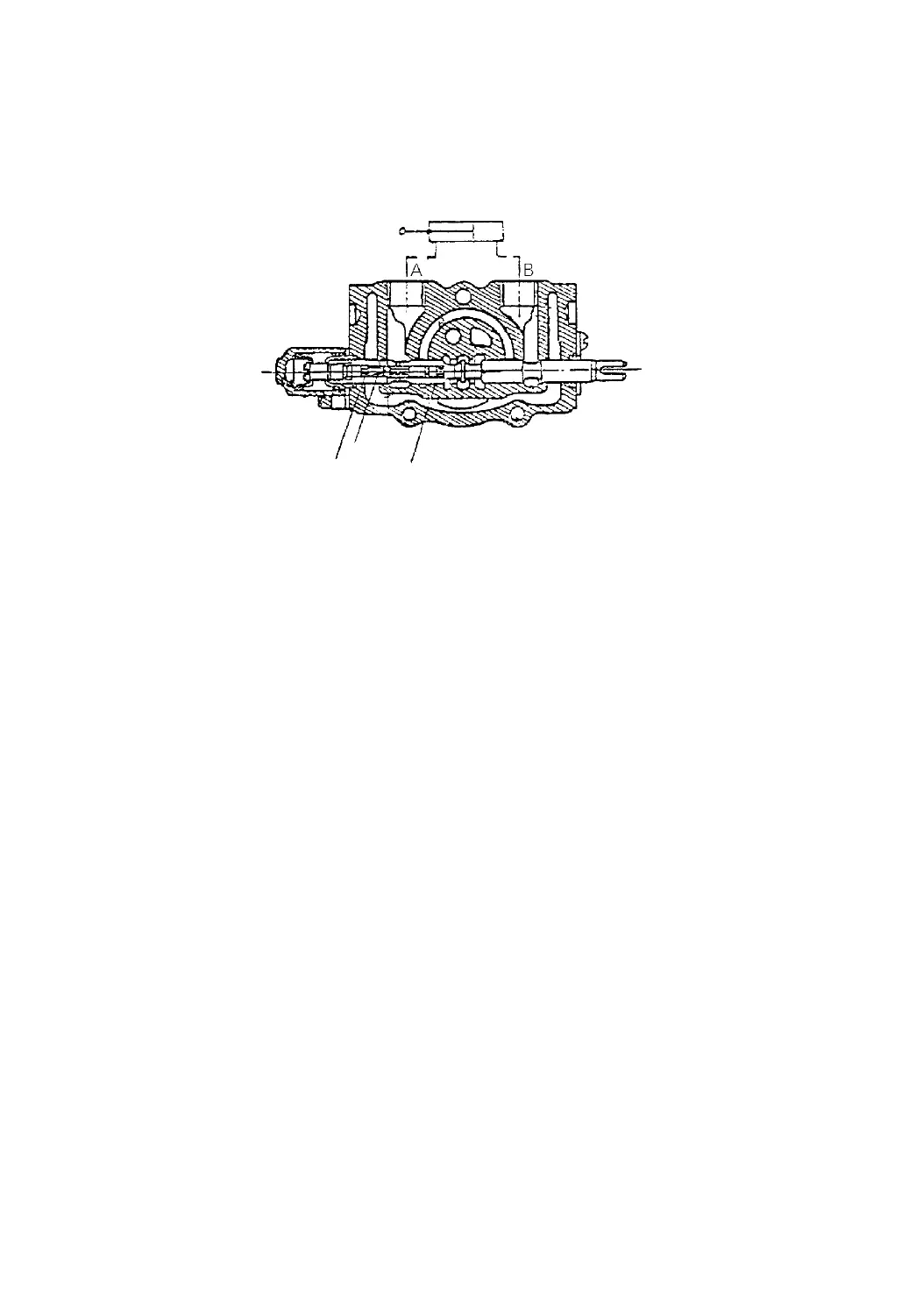

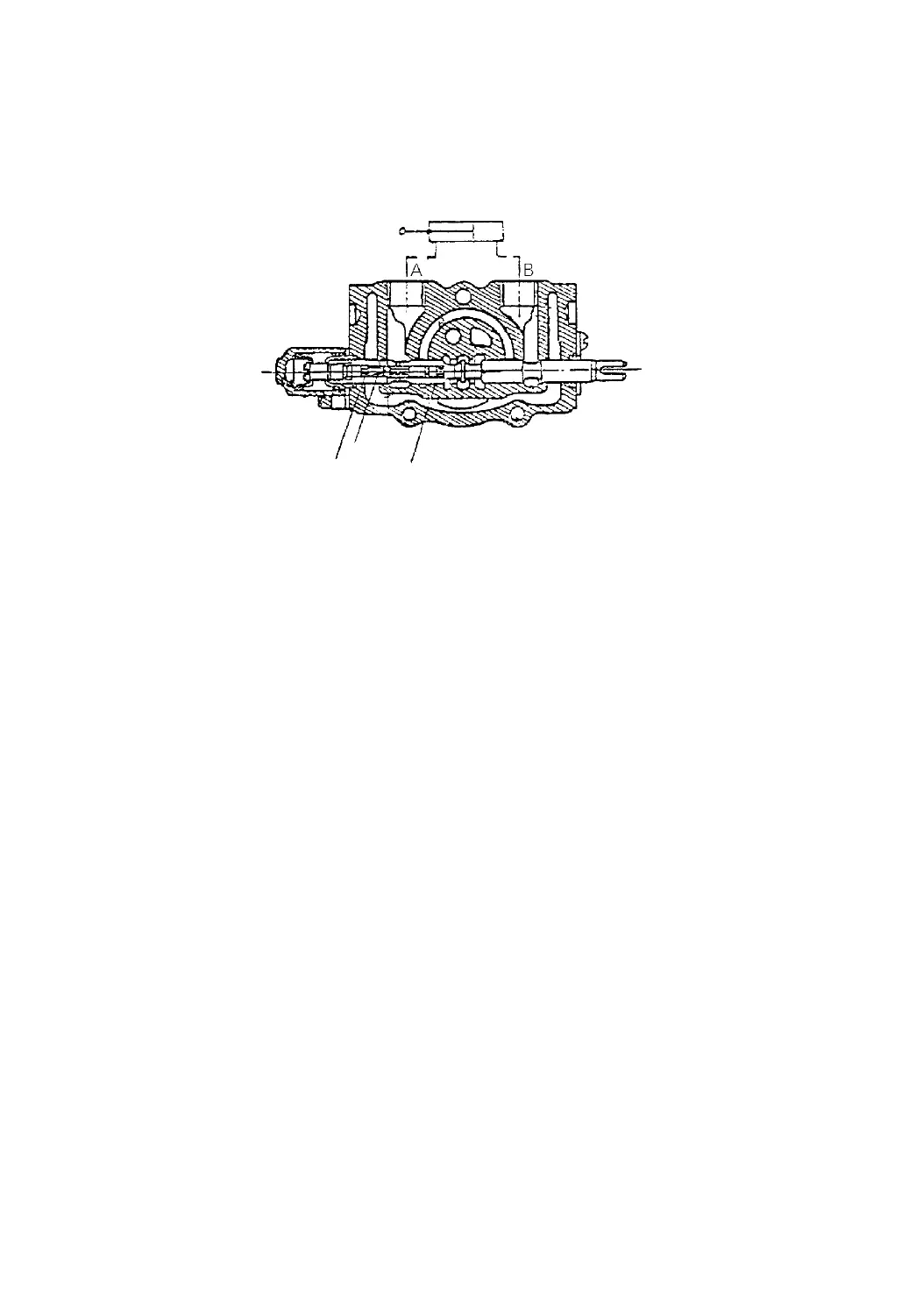

forward when the engine is at rest, even if the tilt lever is pushed with a full load. The

construction of the tilt-lock valve. (See Fig.9-6)

Fig.9-6

The port A and B are connected respectively to the front and the rear chambers in

the tilt cylinder. When the spool is pulled out, the pressure oil flows through the port A

and the oil in rear chamber flows into the oil tank through the port B and the mast is

tilted backward.

When the spool is pushed in, the pressure oil flows through the port B and moves

the tilt-lock valve to let the port A connect the low pressure tank and the tilt cylinder

and the mast is tilted forward. When the engine stops, no pressure oil moves the tilt-

lock valve, the port A can’t connect the low pressure tank and the tilt cylinder and the

mast can’t be tilted forward.

9.4 Hydraulic System (See Fig.9-7)

The oil from the main pump cones to the control valve first and there is divided

by the flow divider into two parts, one being sent to lift cylinder or tilt cylinder, and

another to the power steering unit in constant flow rate to operate the steering

cylinder. With the spools of the lift and tilt spools in neutral position, the oil from the

pump directly returns to the tank through the passage in the control valve. When the

lift spool is pulled, the oil from the pump flows through the flow regulator valve and

reaches the lower part of the lift cylinder to push the piston up. When pushes the lift

Tilt cylinder

Spring

Valve core

Spool

-75-

Loading...

Loading...