is within the range of 15-20mm.

(2) Make the mast assembly tilt backward, adjust the pulling force of lift chains

and let the tightness of lift chains be equal at b point (See Fig.10-1).

(3) The travels of two lift cylinders should be equal. The travels may be adjusted

by using the cylinder cap(4) (See Fig.9-8).

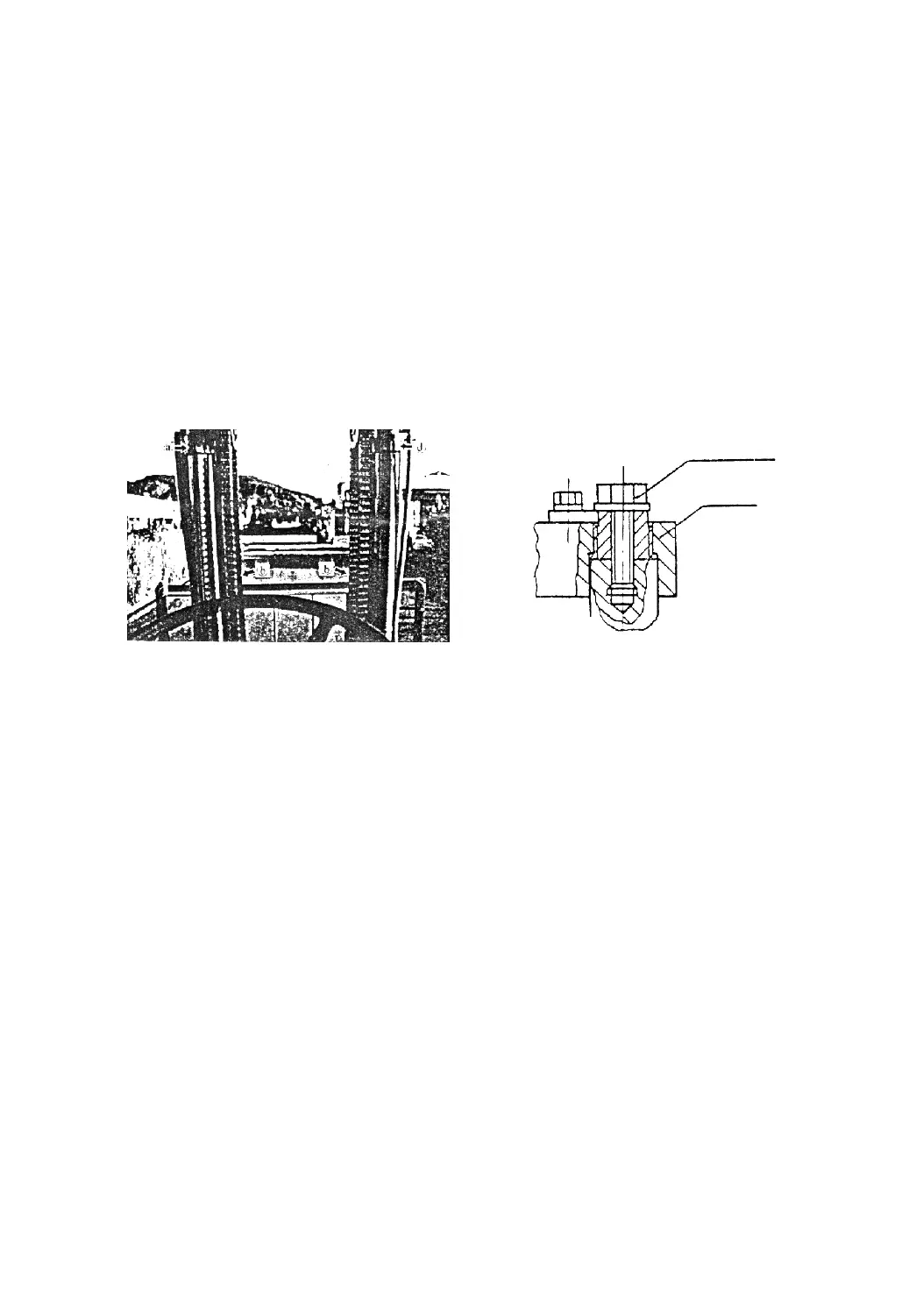

(4) Make use of the set bolt of the right lift cylinder cap (See Fig.10-2) to

eliminate the difference in height between the right and left cylinder caps.

Fig.10-1 Fig.10-2

10.5 Rust Protection and Maintenance of the Lift Cylinder

The moisture content of the atmosphere and salt fog will go into the cylinder

through the oil return pipe and the clearance between the sealing parts and other parts

if the cylinder is not used for a long time. And thus the piston rod and inside of the

cylinder barrel will be corroded and the exterior of the cylinder will become rusty.

Once the cylinder gets rusty, it will be no longer serviceable.

Rust protection and maintenance measures:

(1) Rust protection of the piston rod exposed outside: wipe the surface of the

piston rod with oil cloth evenly every one or two week in sunny days so as to form oil

firm. If it is humid weather, do as above every 3-5days.

(2) Rust protection of the interior of the cylinder: lift and lower the mast several

times in sunny days every 3-5 days to make the interior of the cylinder be fully oil

lubricated; do the above every 2-3 days in humid weather.

Adjusting bolt

Active beam

-91-

Loading...

Loading...