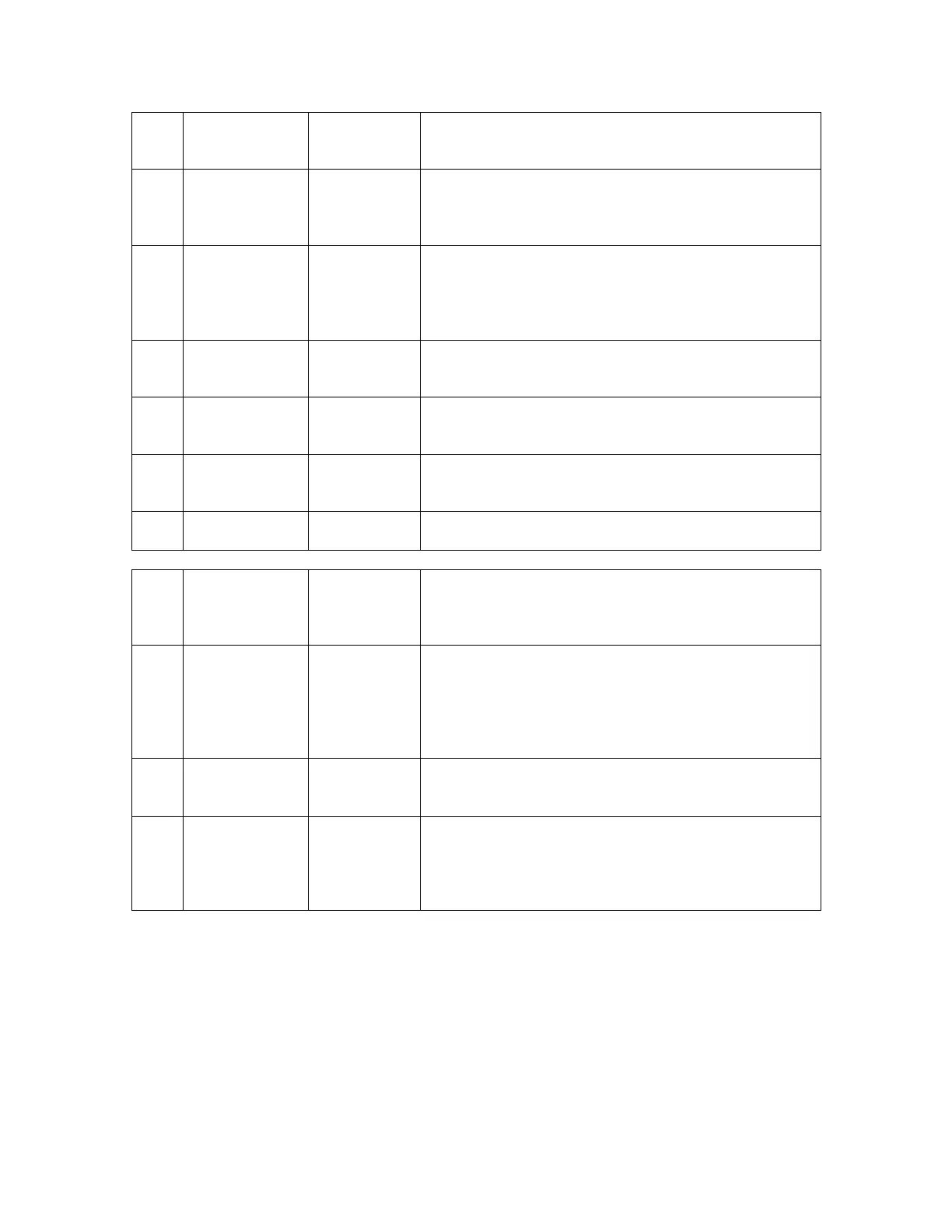

44

Solution: Check the value of sensor and connection of

wires and the fault is inside the controller in case of no

problem found.

During software testing, there are many reasons for such

fault such as: CAN communication fault and EEPROM

READ/WRITE ERROR etc. Check the parameter of

“DEBUG MODE”, the value must be “OFF”.

Wrong contents are found when testing the main memory:

The registration address is “DIRTY” and the fault will

restrict the operability of vehicle.

Fault analysis: Switch on the key after switching it off and

change the controller if the trouble still exists.

Auxiliary

output drive

fault

Auxiliary coil drive circuit can not drive load. The

equipment or drive coil is damaged. Change the

controller.

The fault will be hinted when calibrating the current gain.

No treatment is needed and it will automatically disappear

when calibration is finished.

CAN communication fault between pump and traction.

Check CAN wiring, software setting and edition

information.

It is the time for service and maintenance is needed.

The output signal of temperature sensor of controller

exceeds the range.

The fault has nothing to do with external parts and change

the controller.

During startup, the controller tests if the voltage of battery

is within the nominal scope. Check if the value of

BATTERY VOLTAGE parameter in the menu conforms to

that on the voltmeter. If not, make them conform to each

other with the function of ADJUST BATTERY.

Change the battery.

Wrong selection of SLIP PROFILE PARAMETERS.

Check the setting of these values in the hardware setting

parameters.

Short circuit of the driving electric circuit of the

electromagnetic brake or auxiliary electric brake. Check if

there is short circuit between the A16 and BATT.

Circuit ault of the drive unit of the logic card; change the

controller.

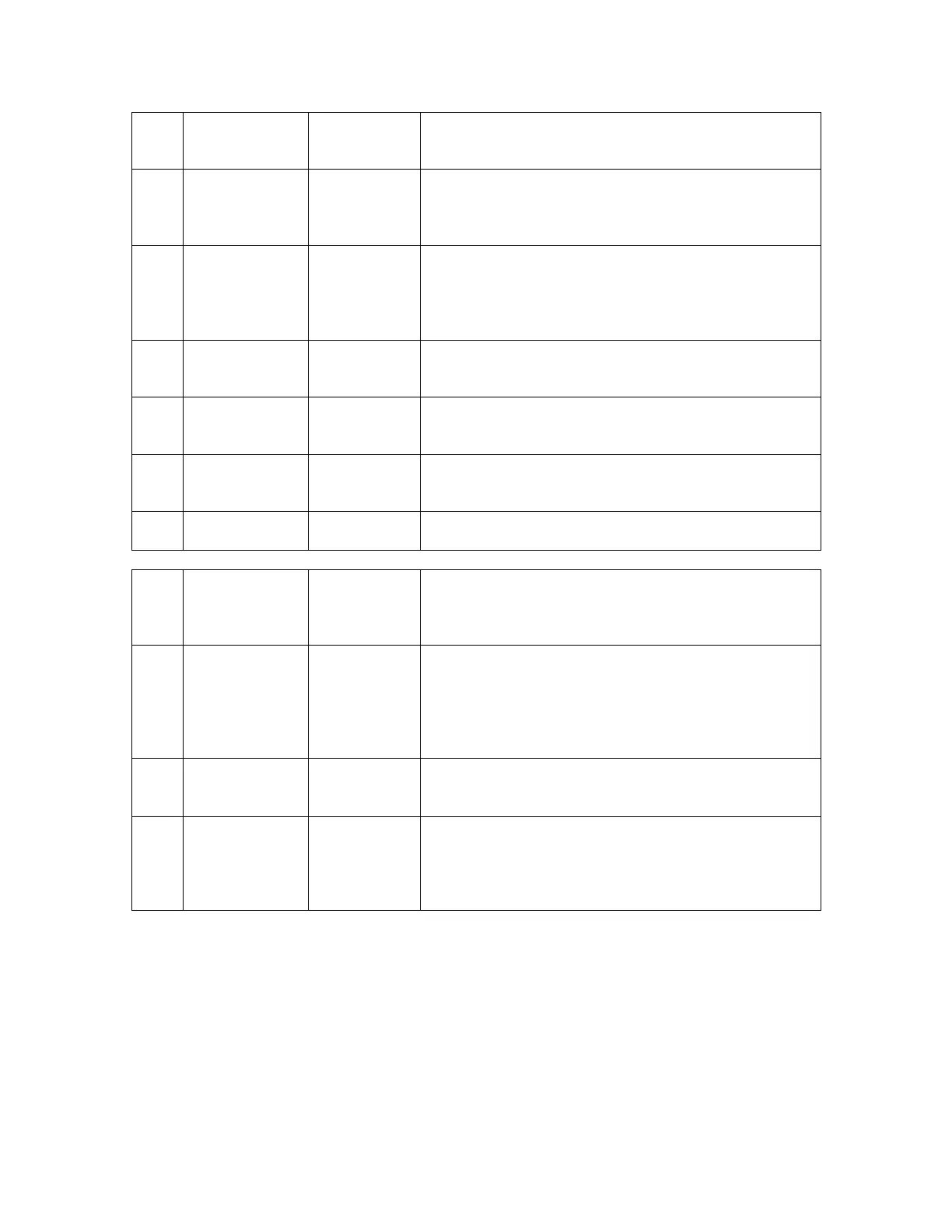

Loading...

Loading...