45

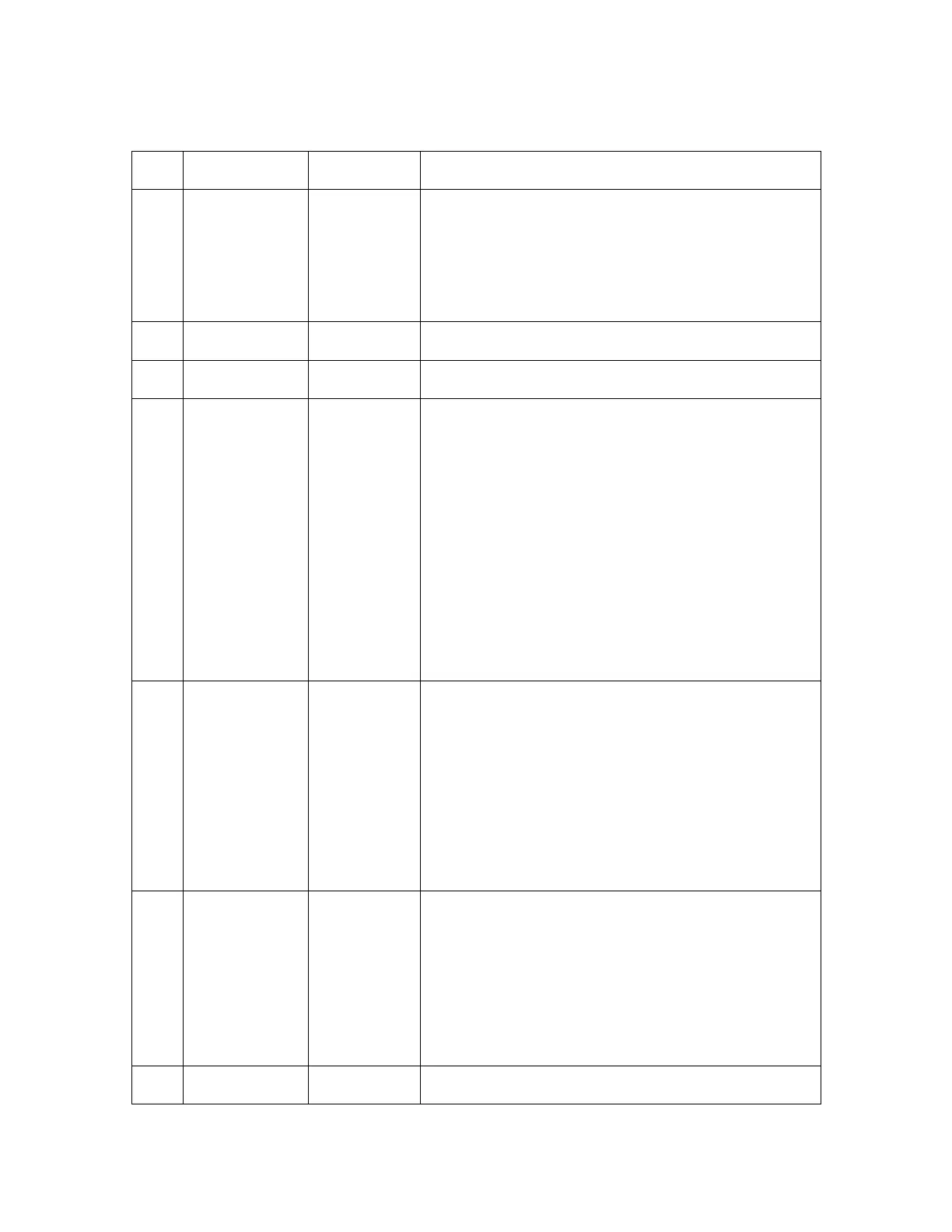

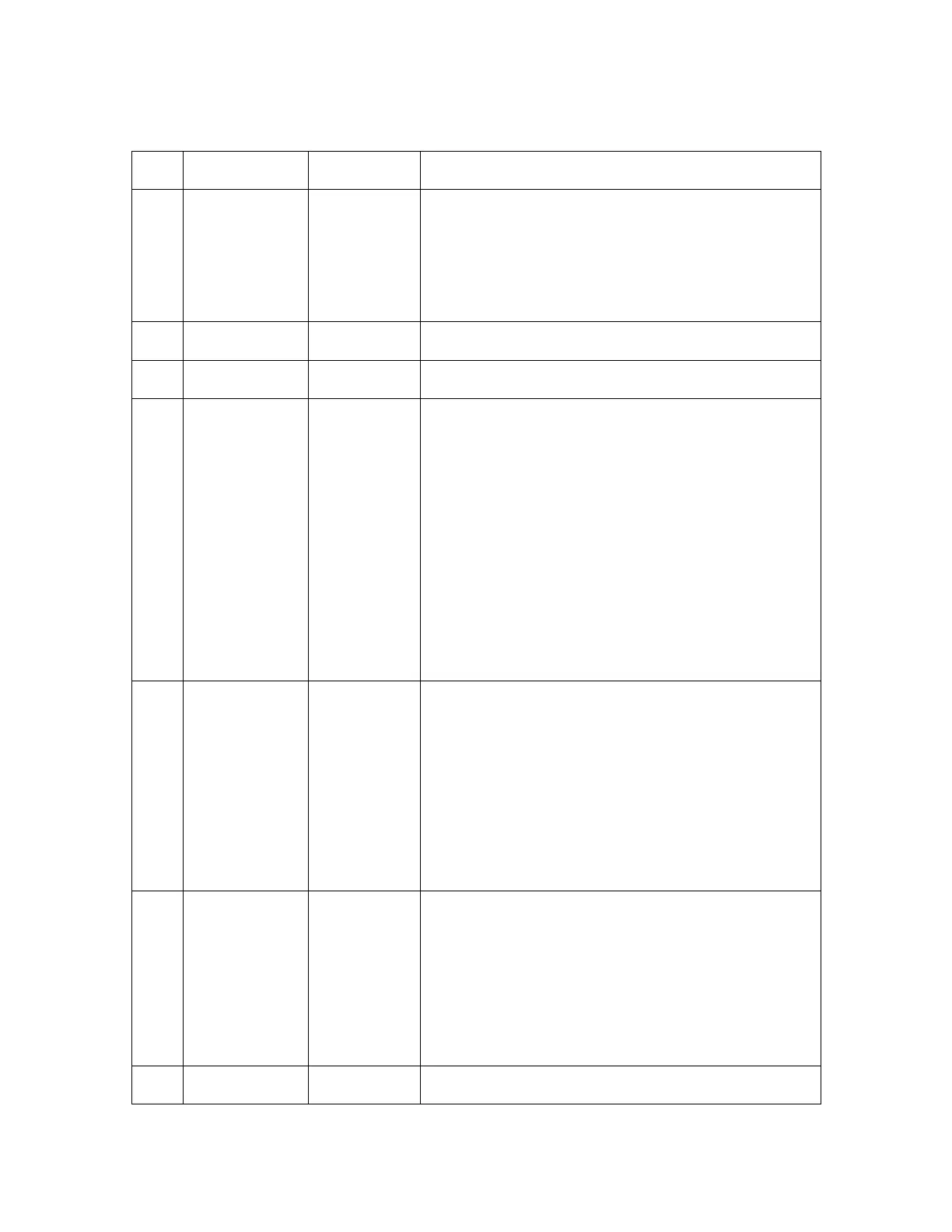

Table 4-6 Common fault of pump control system

The fault is in the internal memory for storing and

regulating parameters. When the fault appears, the

machine automatically stops. If the fault still exists, when

reconnecting it after switching off the electric lock,

change the controller. If the fault disappears, the

parameters previously stored will be replaced with default

value.

Current protection function failure of logic card: change

the controller.

Circuit failure of phase voltage feedback hardware on

logic card. Change the controller.

The failure produced when the function of low or over

voltage acts. In 24V system, the voltage detected by

controller exceeds 45V or lower than 9V. In 48V system,

the voltage detected by controller exceeds 65V or lower

than 11V. Possible causes:

(1) Check if there is short circuit in the electric circuit

system such as DC-DC and brake coils etc or if the input

power supply contact of controller is good.

(2) If the battery voltage is excessively low or high.

(3) Check B+ and B and see if the power cable on the

wiring terminal of contactor etc is tightly fixed.

(4) If the voltage calibration parameter of controller is in

consistent with actual voltage.

(5) There is circuit fault of overvoltage protection

hardware on logic card, change the controller.

Cause:The high-end voltage of MOS during startup is

66% smaller than the capacitor voltage or this voltage is

smaller than the required value in the operation of motor.

Possible causes:

(1) Wiring of motor is incorrect or there is circuit problem

in motor. Check if three-phase connection of motor is

correct, if there is any leakage of electricity on ground and

circuit break of motor coil.

(2) If actuation of main contactor is rigid and if there is

any wearing on contact?

(3) Change the controller .

Cause:During startup, the low-end voltage of MOS tube

is 10% higher than that of normal battery voltage or the

phase voltage is higher than 1/2 of battery voltage.

Possible cause:

(1) The wiring of motor is incorrect or there exists

problem in motor circuit . Check if three-phase connection

of motor is correct, if there is any leakage of electricity on

the ground and circuit break of motor coil. (2) Change the

controller

The signal output by current sensor detected by

micro-control system exceeds the scope allowed for

Loading...

Loading...