50

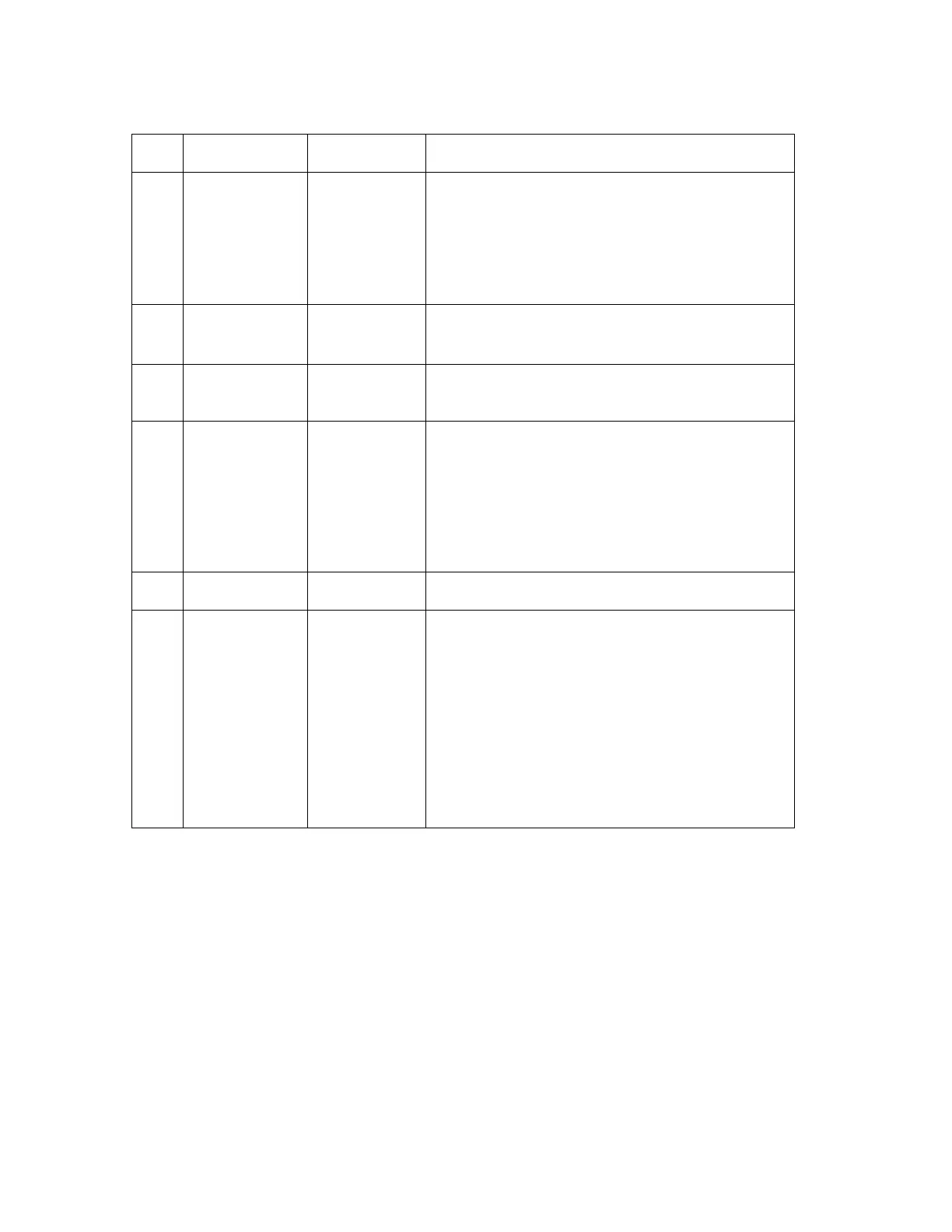

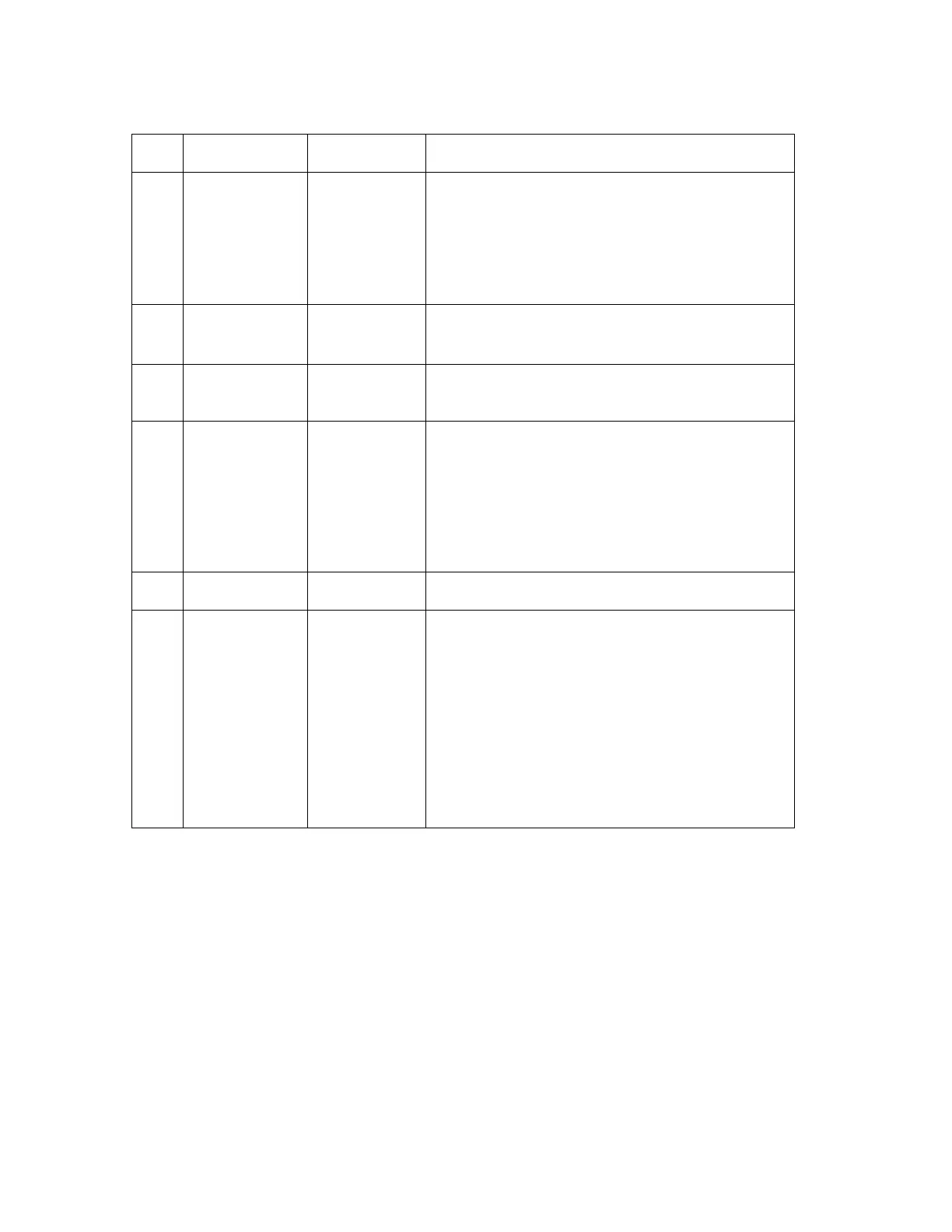

Table 4-7 Common fault for instrument system

Trouble is in the internal memory to store and

regulate the parameters. Machine will automatically

stops in case of trouble. The controller should be

changed if the trouble still exists after reconnection

when the electric lock is turned off. If the trouble

disappears, the parameters stored before will be

replaced with default value.

Circuit failure of A19 or A20 output port,change the

instrument if it has nothing to do with external

components.

Drive coil short circuit: Test if there is short circuit

on the device connecting with output port of the

instrument, otherwise, change the instrument.

CAN

communication

failure

Instrument no longer receives the data from CAN

BUS data wire. In case that the fault code and other

alarm signal are displayed together, the fault may

possibly be on the CAN interface of the instrument,

because the instrument can not receive any message.

So, suggest to check the wiring and connection of

CAN , or the CAN interface fault of other modules

will appear in the CAN network.

It is the time for maintenance (service).

The input of hydraulic oil level is valid during

startup.

Trouble Diagnosis:

Check if the related digital input on instrument (A9)

is valid(Refer to TESTER MENU)

Check the effective level form(+VB or GND) of the

input end (Refer to SET OPTION MENU).

(1) If the input is valid, check the relating switch,

circuit and oil level.

(2) If the input is invalid, there might have an input

circuit trouble in the intelligent instrument.

Loading...

Loading...