23

for the technician

First firing, regulation and servicing instructions

— On “SE” models, plug silicon rubber pipe on “Vent” plug [3] on gas valve. WARNING: after

plugging the pipe on “Vent” plug, the value on manometer may decrease due to pressure com-

pensation. This is normal and doesn’t require any further adjustment;

— fully screw outlet pressure tapping point screw [1] and check for gas leaks.

Regulation programming

All these operations must be performed by QUALIFIED TECHNICIANS ONLY. Operations

performed by not qualified persons can cause MALFUNCTIONS and/or DAMAGE. Hermann

cannot be considered liable for eventual damages caused by not qualified persons.

Do not modify default settings if not necessary

GENERAL PROCEDURE

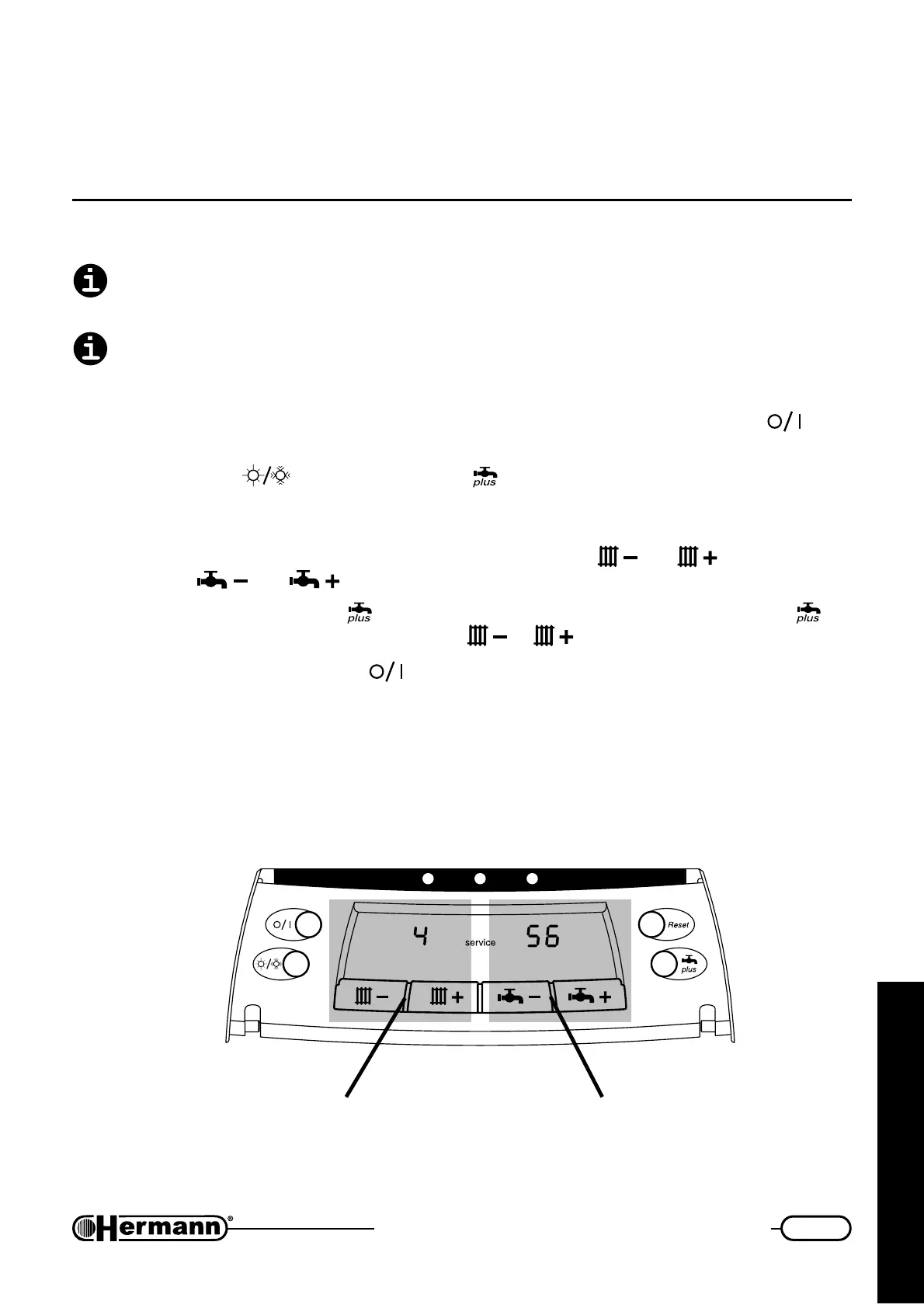

— With control panel in normal position, open its cover and turn off boiler pushing

knob:

green light flashes:

— Keep both knobs

(Summer/Winter) and pushed for 5 seconds contemporary: display

shows “service” with a number on the left (from here on called ‘PARAMETER’) and another

number on the right (from here on called ‘VALUE’);

— Select number of PARAMETER to be modified pushing knobs

and ; change VALUE

by pushing and .

— To STORE a new value push

. If you want NOT to store the value, do NOT push but

simply select another parameter (by pushing or ).

— To quit programming mode push

.

Note: Once quitted program mode, it is necessary to wait about 90 seconds for complete motorised

mixing valve calibration. Such delay can be temporary excluded through programming parameter

n°9 described here below.

630A

To edit the

VALUE

To select the

PARAMETER

Loading...

Loading...