6

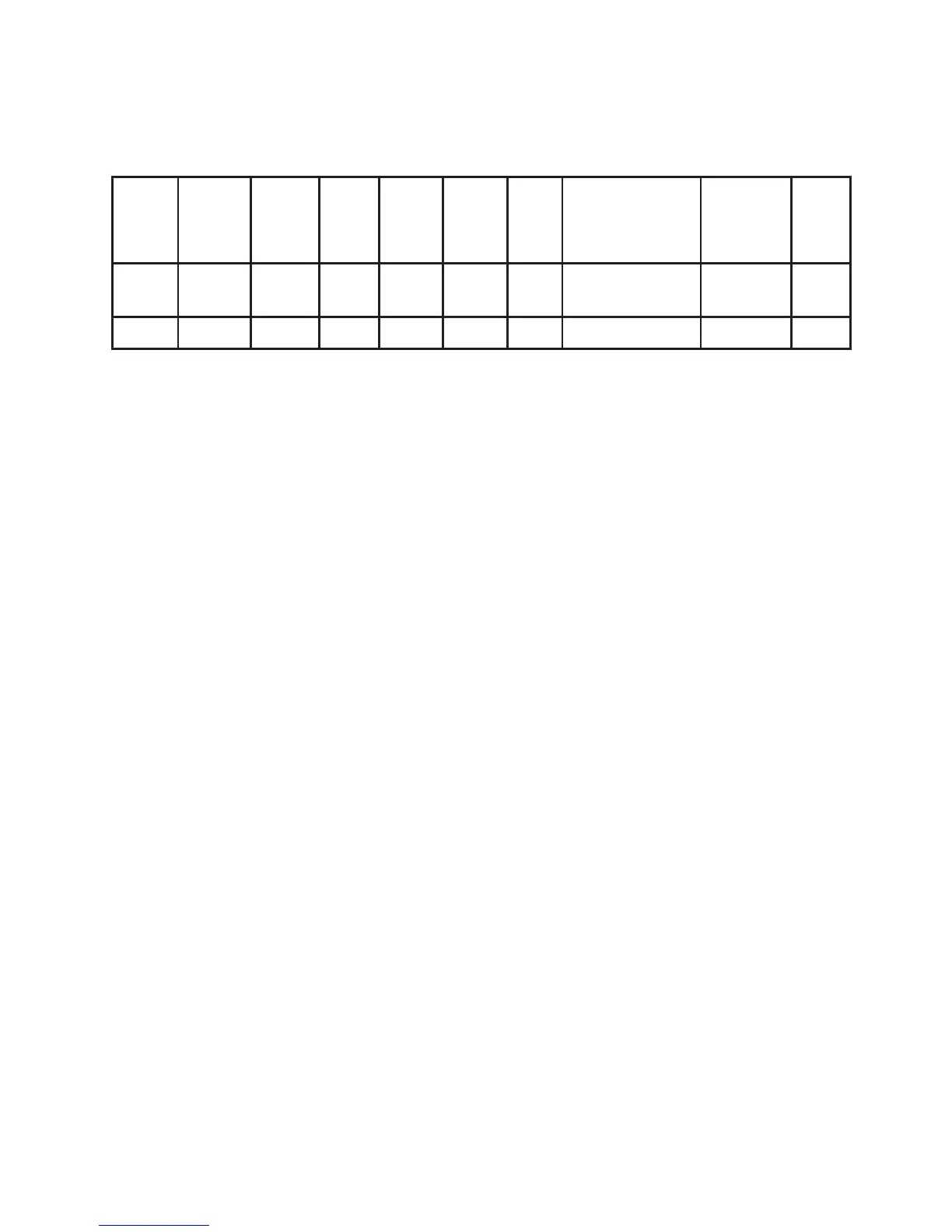

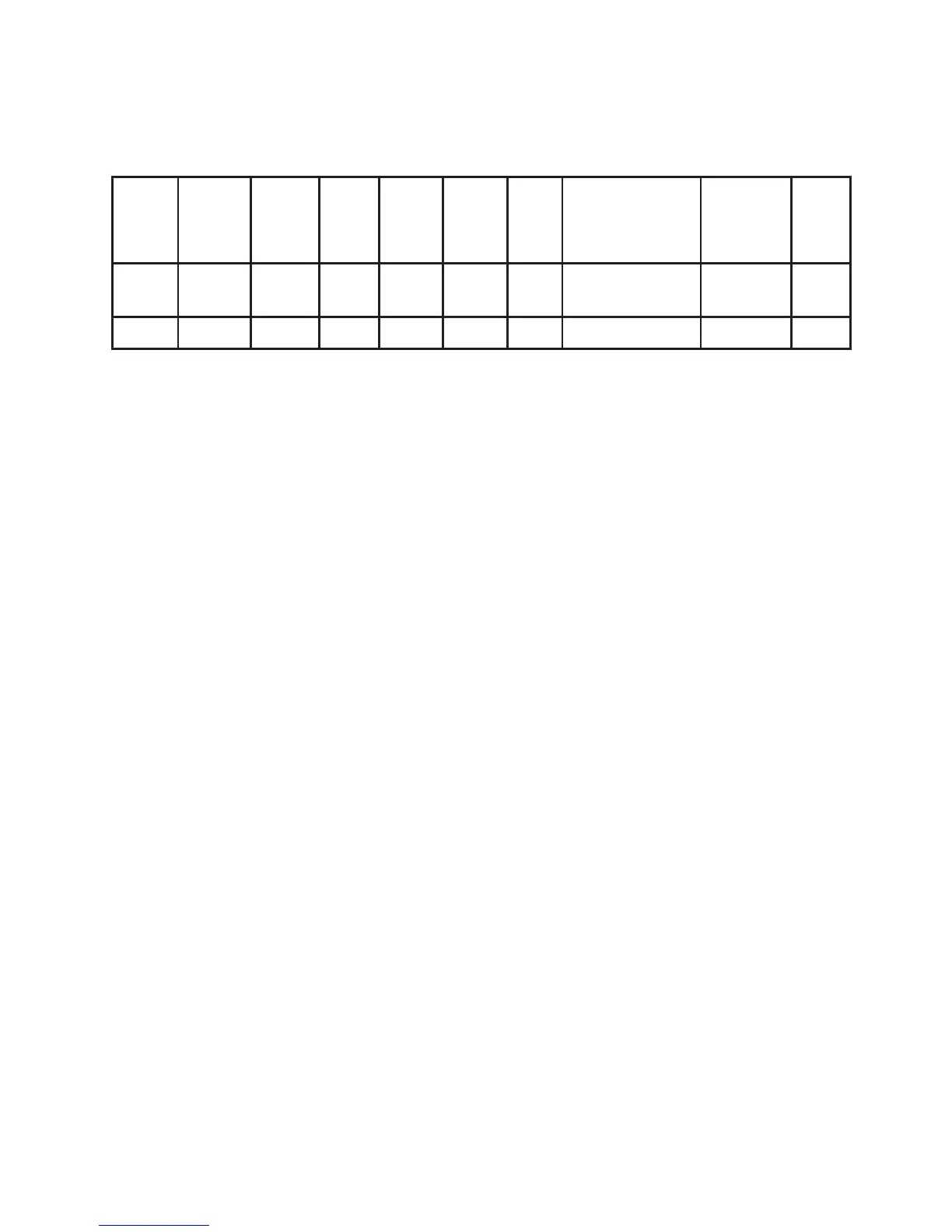

Stove data table in accordance with EN 13240 testing.

Stove

type

Scan-Line

Nominal

fluegas

temp.

c°

Smoke

stub

mm

Fuel

volume

kg

Draught

min

mbar

Nominal

output

tested

kW

Heat

output

kW

Distance to flamma-

ble

materials in mm

behind at the the

stove sides

Distance to

tfurnitures

from the

stove in mm

Stove

weight

kg

15

16

339 ø150 2.5 0.11 7 7 150 200 800 160

150

16XL 331 ø150 2.5 0.10 8 8 200 200 800 185

The nominal output is the output to which the stove has been tested.

Testing should be carried

out with the primary airflow closed and the secondary airflow fully open.

Take care when emptying the ash pan,

as cinders can continue to burn in the

ash for long periods of time.

OPERATIONAL PROBLEMS

The chimney must be swept at least

once a year, we recommend the use of

a NACS (national association of chim-

ney sweeps) registered chimney sweep.

In the event of smoke or malodorous

fumes being produced, you must first

check to see whether the chimney is

blocked. The chimney must, of course,

always provide the minimum draught

necessary to ensure that it is possi-

ble to regulate the fire. Please note,

however, that chimney draft is de-

pendent on the weather conditions.

In high winds, the draft can become

so powerful that it may be necessary

to fit a damper in the flue gas pipe to

regulate the draft. When cleaning the

chimney, soot and other deposits may

come to fall on the smoke plate. In ca-

ses where the wood burns too quickly,

this may be due to excessive chimney

draught. You should also check to

make sure that the door seal and ash-

pan seal is intact and correctly fitting.

If the stove it generating too little

heat, this may be because you are fi-

ring with wet wood. In this case, much

of the heating energy is used to dry

the wood, resulting in poor heating

economics and an increased risk of

soot deposits in the chimney.

MAINTENANCE

The surface of the stove has been tre-

ated with heat-resistant paint.

The stove should be cleaned with a

damp cloth. Any damage to the surface

in the form of chips or scratches

can be

repaired using touch-up paint, which is

available in spray cans. If the stove has

become grey in colour due to overhea-

ting, touch-up paint of this kind can

be used to repaint the stove entirely.

However, in this case, the stove should

be dismantled and the surface treat-

ment should be performed outdoors

or in a purpose-built room.

Cleaning the glass

Incorrect firing, for example using wet

wood, can result in the viewing win-

dow becoming covered in soot. This

soot can be easily and effectively rem-

oved by using proprietary stove glass

cleaner.

Loading...

Loading...