Snap rings can slip and fly off when

removing and installing them. Also, the snap

ring pliers tips may break. Always wear eye

protection when using snap ring pliers.

Hammers

Various types of hammers are available to fit a number of applications. Use a ball-

peen hammer to strike another tool, such as a punch or chisel. Use soft-faced

hammers when a metal object must be struck without damaging it. Never use a metal-

faced hammer on engine and suspension components because damage occurs in

most cases.

Always wear eye protection when using hammers. Make sure the hammer face is in

good condition and the handle is not cracked. Select the correct hammer for the job

and make sure to strike the object squarely. Do not use the handle or the side of the

hammer to strike an object.

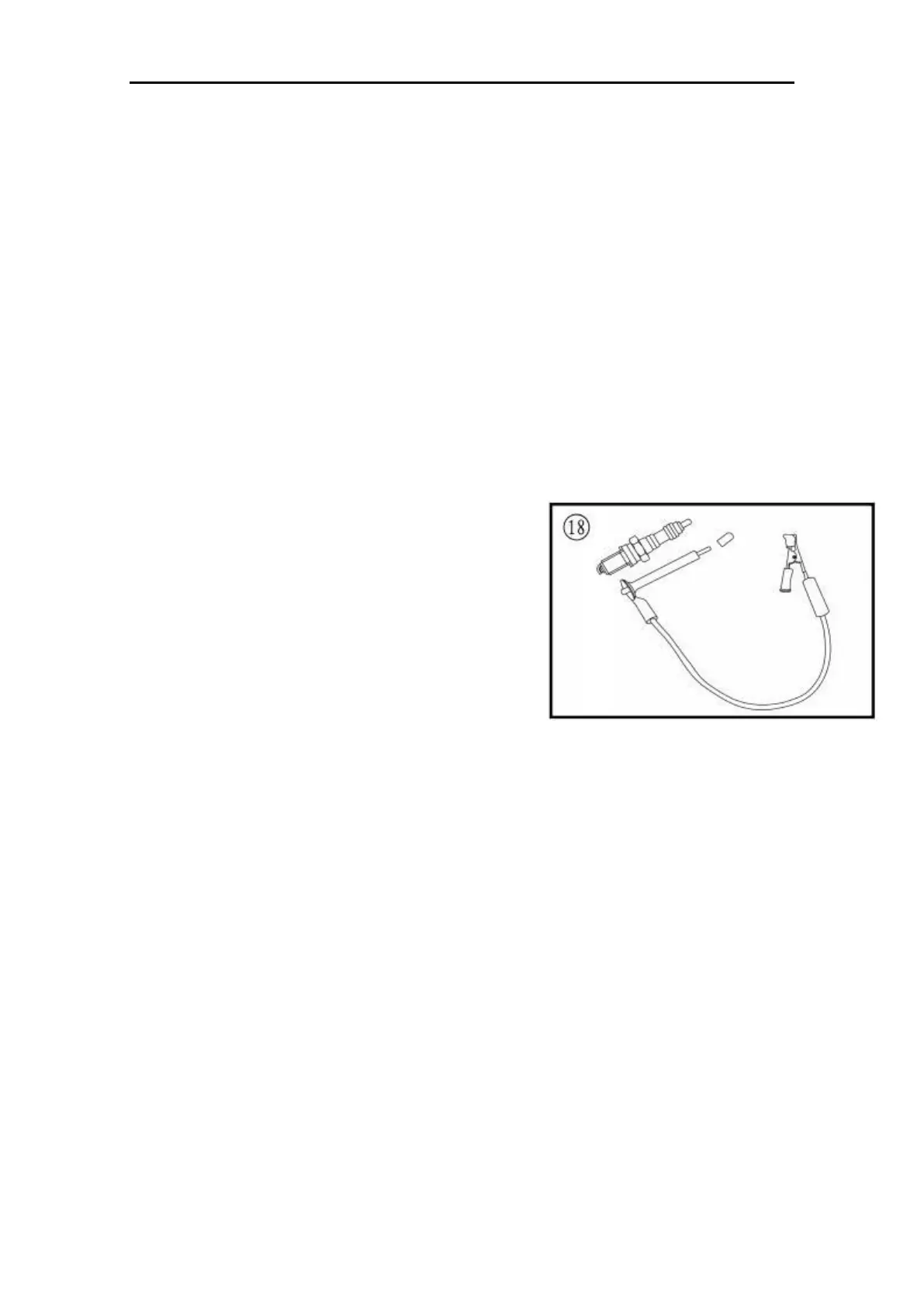

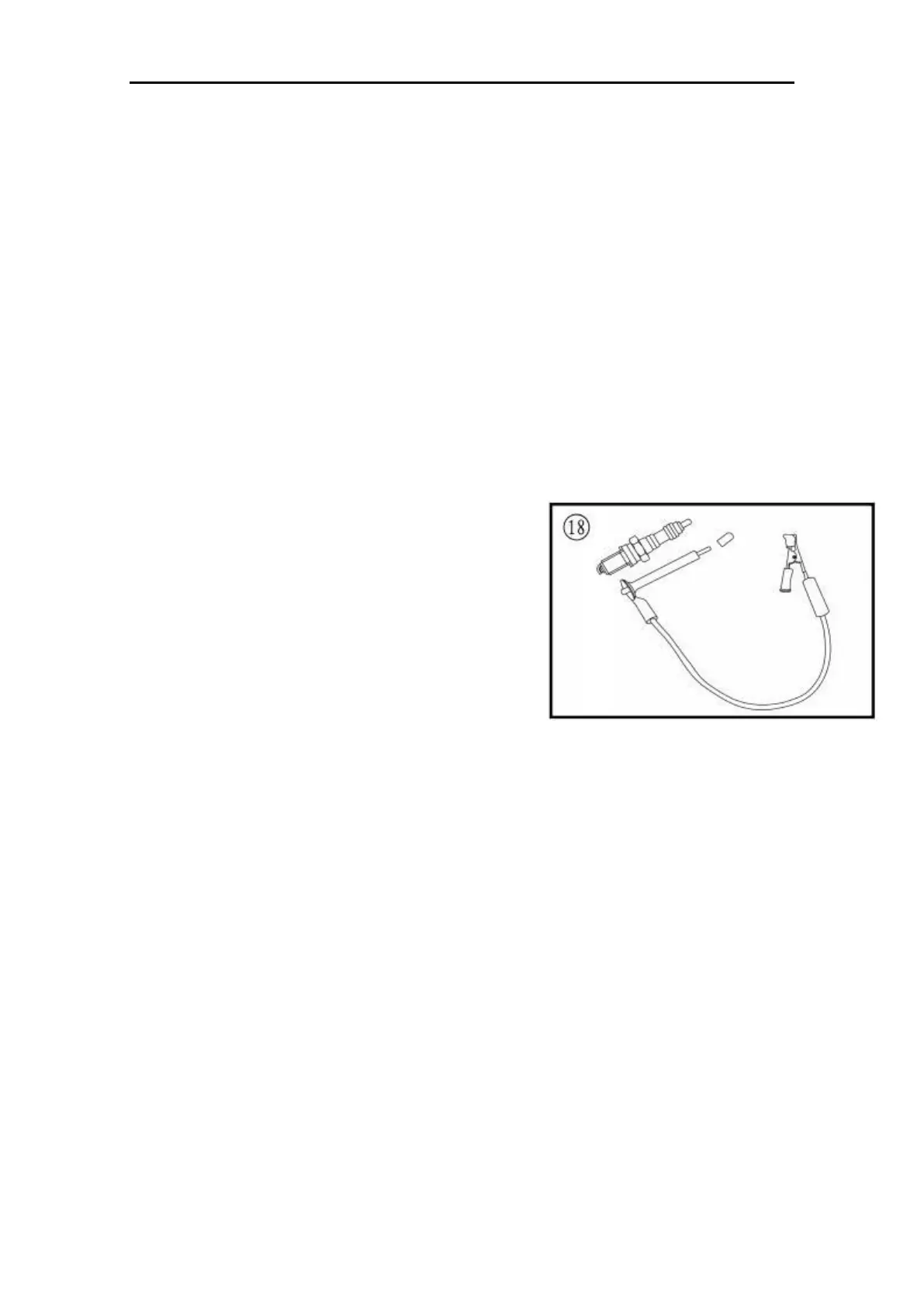

Ignition Grounding Tool

Some test procedures require turning the engine

over without starting it. To prevent damage to the

ignition system from excessive resistance or the

possibility of fuel vapor being ignited by an open

spark, remove the spark plug cap and ground it

directly to a good engine ground with the tool shown

in (Figure 18).

Make the tool shown from a No.6 screw and nut,

two washers, length of tubing, alligator clip, electrical

eyelet and a length of wire.

PRECISION MEASURING TOOLS

The ability to accurately measure components is essential to perform many of the

procedures described in this manual. Equipment is manufactured to close tolerances,

and obtaining consistently accurate measurements is essential to determine which

components require replacement or further service.

Each type of measuring instrument is designed to measure a dimension with a

certain degree of accuracy and within a certain range. When selecting the measuring

tool, make sure it is applicable to the task.

As with all tools, measuring tools provide the best results if cared for properly.

Improper use can damage the tool and cause inaccurate results. If any measurement is

questionable, verify the measurement using another tool. A standard gauge is usually

provided with micrometers to check accuracy and calibrate the tool if necessary.

Precision measurements can vary according to the experience of the person

performing the procedure. Accurate results are only possible if the mechanic

possesses a feel for using the tool. Heavy-handed use of measuring tools produces

less accurate results. Hold the tool gently by the fingertips to easily feel the point at

Loading...

Loading...