which the tool contacts the object. This feel for the equipment produces more accurate

measurements and reduces the risk of damaging the tool or component. Refer to the

following sections for specific measuring tools.

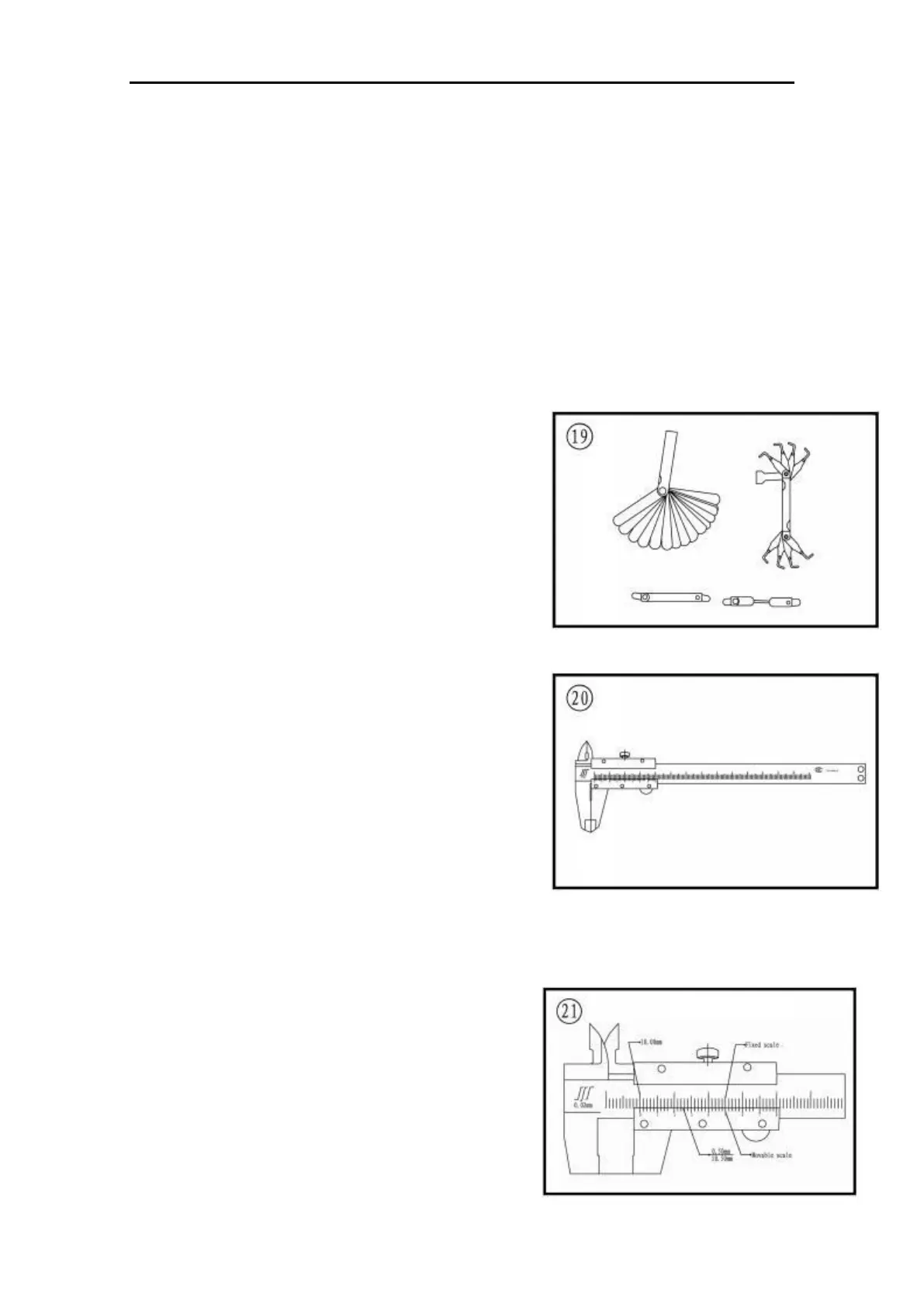

Feeler Gauge

Use feeler or thickness gauges (Figure19) for measuring the distance between two

surfaces.

A feeler gauge set consists of an assortment of

steel strips of graduated thickness. Each blade is

marked with its thickness. Blades can be of various

lengths and angles for different procedures.

A common use for a feeler gauge is to measure

valve clearance. Use wire (round) type gauges to

measure spark plug gap.

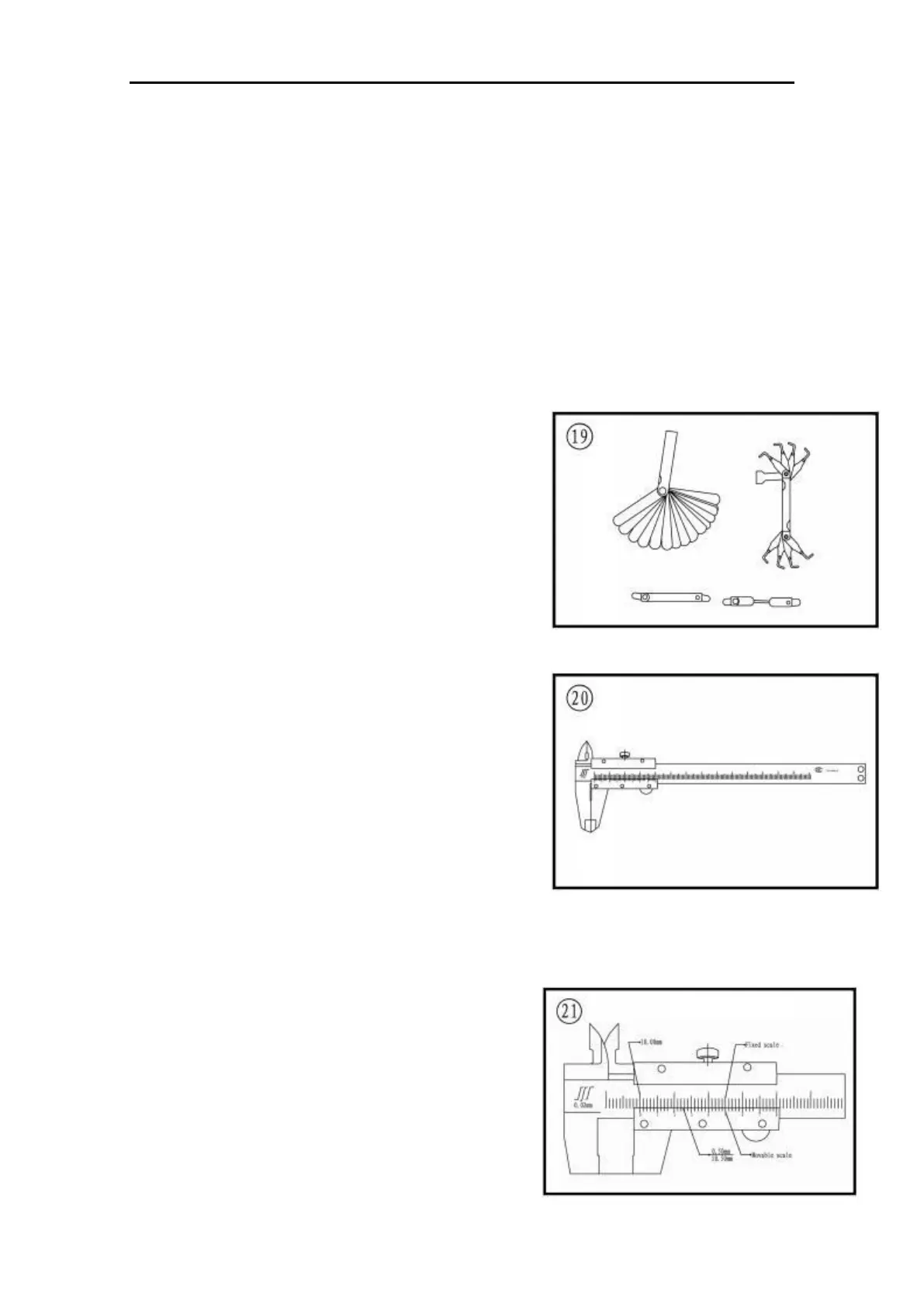

Calipers

Calipers (Figure 20) are excellent tools for obtaining inside, outside and depth

measurements. Although not as precise as a

micrometer, they allow reasonable precision, typically

to within 0.02mm or 0.05 mm (0.001 in.). Most

calipers have a range up to 150 mm (6 in.).

Calipers are available in dial, venire or digital

versions. Dial calipers have a dial readout that

provides convenient reading. Venire calipers have

marked scales that must be compared to determine

the measurement. The digital caliper uses a liquid-

crystal display (LCD) to show the measurement.

Properly maintain the measuring surfaces of the caliper. There must not be any dirt

or burrs between the tool and the object being measured. Never force the caliper to

close around an object. Close the caliper around the highest point so it can be removed

with a slight drag. Some calipers require calibration.

Always refer to the manufacturer’s instructions when

using a new or unfamiliar caliper.

To read a vernire. Calipers refer to Figure 21.

The fixed scale is marked in l-mm increments. Ten

individual lines on the fixed scale equal 1 cm. The

movable scale is marked in 0.05 mm (hundredth)

increments. To obtain a reading, establish the first

number by the location of the 0 line on the movable

scale in relation to the first line to the left on the

Loading...

Loading...