For frozen screws, apply penetrating fluid as

described, the insert a screwdriver in the slot and

rap the top of the screwdriver with a hammer. This

loosens the rust so the screw can be removed in the

normal way. If the screw head is too damaged to

use this method, grip the head with locking pliers

and twist the screw out.

Avoid applying heat unless specifically

instructed. Heat may melt, warp or remove the

temper from parts.

Removing Broken Fasteners

If the head breaks off a screw or bolt, several methods are available for removing

the remaining portion. If a large portion of the remainder projects out, try gripping it with

locking pliers. If the projecting portion is too small, file it to fit a wrench of cut a slot in it

to fit a screwdriver (Figure 37)

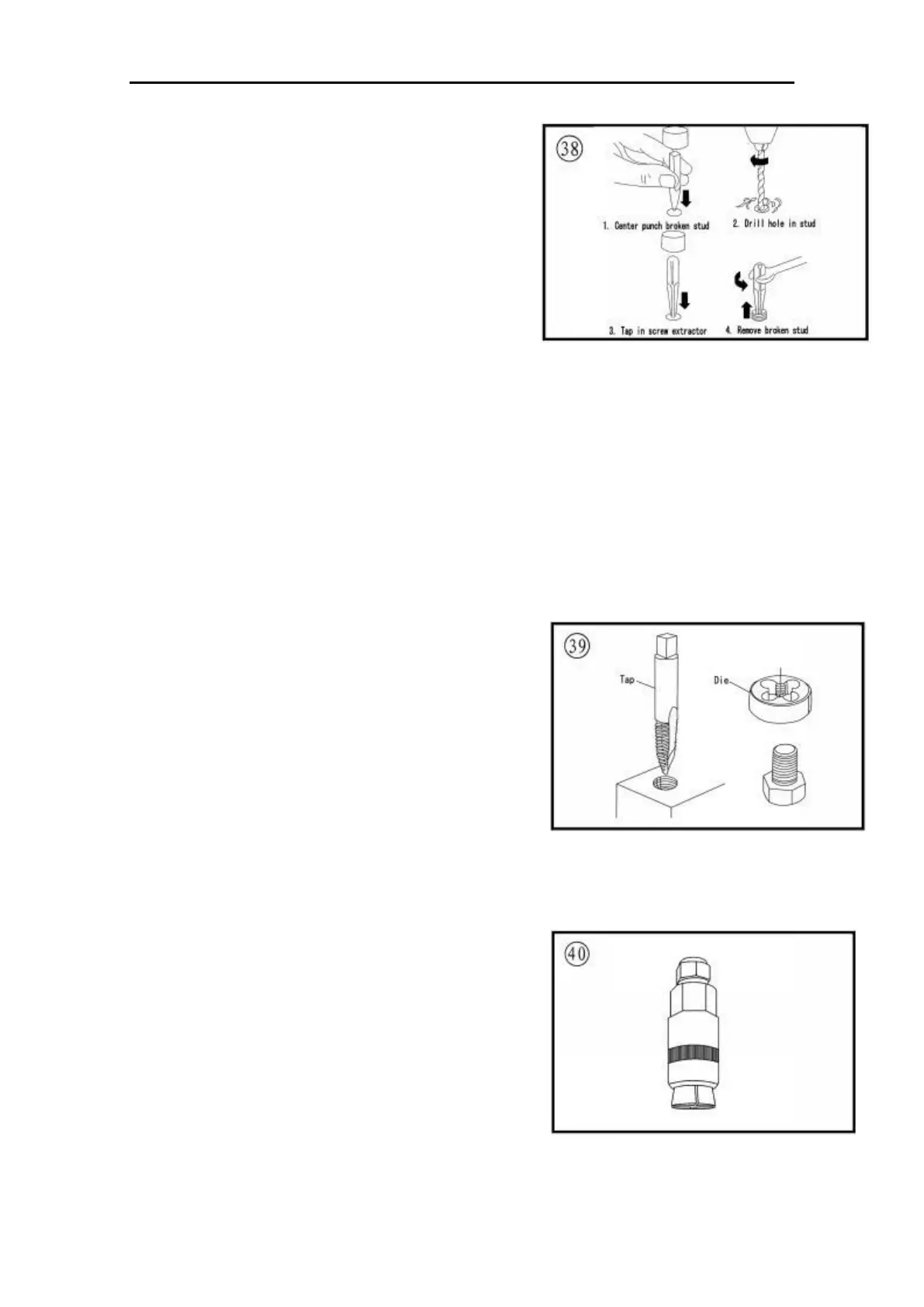

If the head breaks off flush, use a screw extractor. To do this, center punch the

exact center of the remaining portion of the screw or bolt. Drill a small hole in the screw

and tap the extractor into the hole. Back the screw out with a wrench on the extractor

(Figure 38)

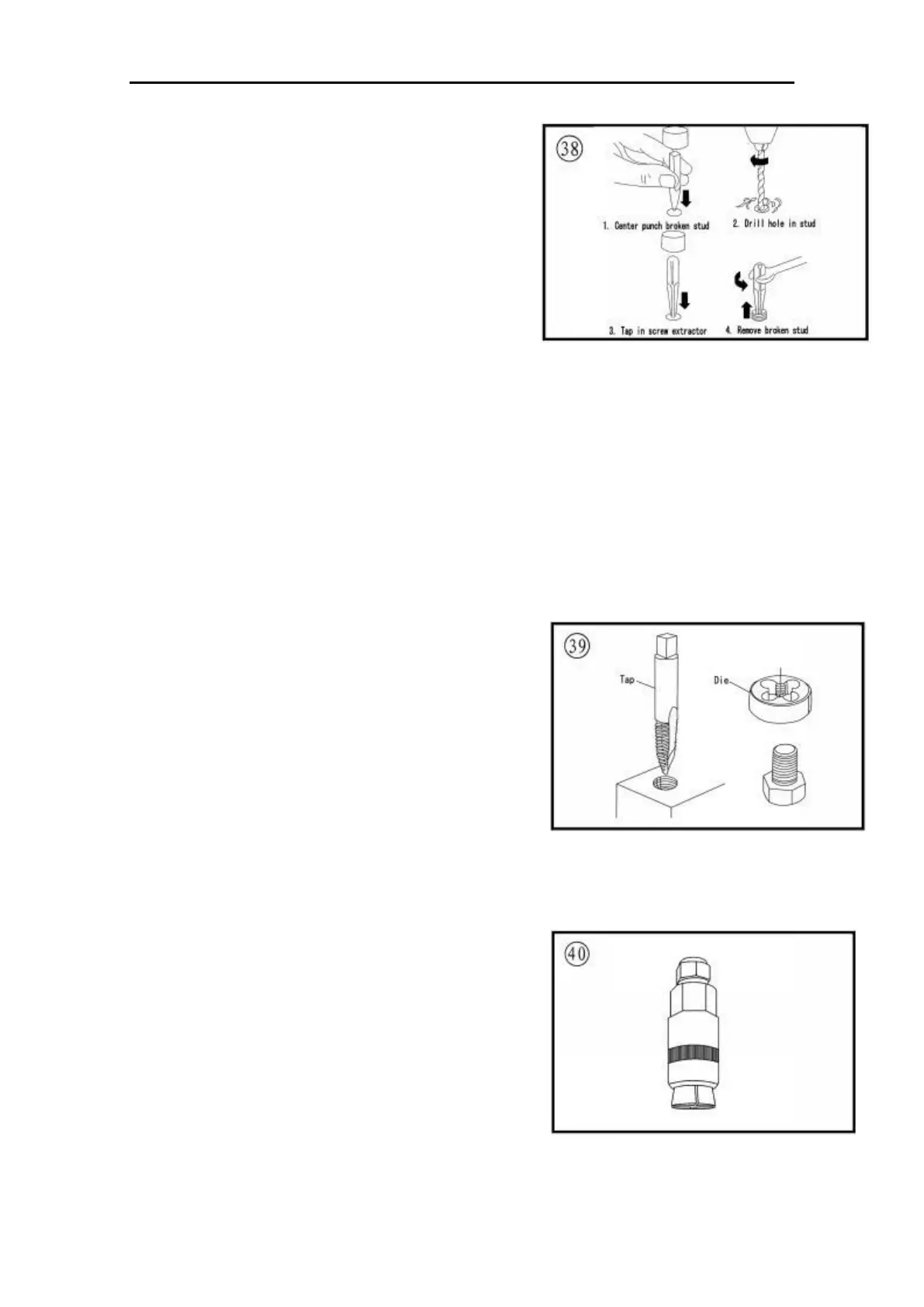

Repairing Damaged Threads

Occasionally, threads are stripped through

carelessness or impact damage. Often the threads

can be repaired by running a tap (for internal threads

on nuts) or die (for external threads on bolts) through

the threads (Figure 39). To clean or repair spark

plug threads, use a spark plug tap.

If an internal thread is damaged, it may be

necessary to install a Helical or some other type of

thread insert. Follow the manufacturer’s instructions when installing their insert.

If it is necessary to drill and tap a hole, refer to Table 8 for metric tap and drill

sizes.

Stud Removal/Installation

A stud removal tool (Figure 40) is available

from most tool suppliers. This tool makes the removal

and installation of studs easier. If one is not available,

thread two must onto the stud and tighten them

against each other. Remove the stud by turning the

lower nut (Figure 41).

Loading...

Loading...