1. Measure the height of the stud above the

surface.

2. Thread the stud removal tool onto the stud and

tighten it, or thread two nuts onto the stud.

3. Remove the stud by turning the stud remover or

the lower nut.

4. Remove any thread locking compound from the

threaded hole. Clean the threads with an

aerosol parts cleaner.

5. Install the stud removal tool onto the new stud

or thread two nuts onto the stud.

6. Apply thread locking compound to the threads of

the stud.

7. Install the stud and tighten with the stud removal

tool or the top nut.

8. Install the stud to the height noted in Step 1 or

its torque specification.

9. Remove the stud removal tool or the two nuts.

Removing Hoses

When removing stubborn hoses, do not exert excessive force on the hose or fitting.

Remove the hose, do not exert excessive force on the hose or fitting. Remove the hose

clamp and carefully insert a small screwdriver or pick tool between the fitting and hose.

Apply a spray lubricant under the hose and carefully twist the hose off the fitting. Clean

the fitting of any corrosion or rubber hose material with a wire brush Clean the inside of

the hose thoroughly. Do not use any lubricant when installing the hose (new or old).

The lubricant may allow the hose to come off the fitting, even with the clamp secure.

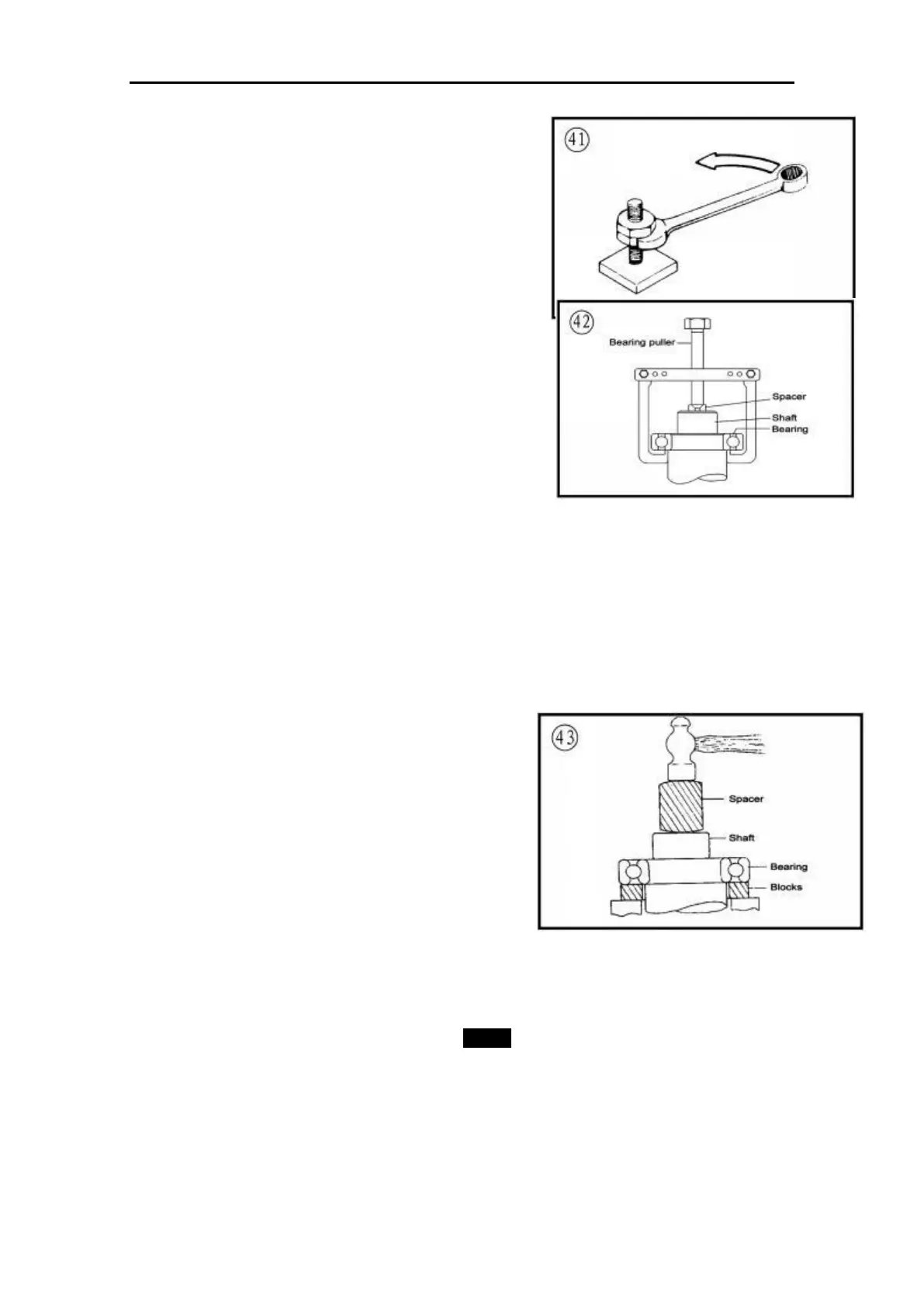

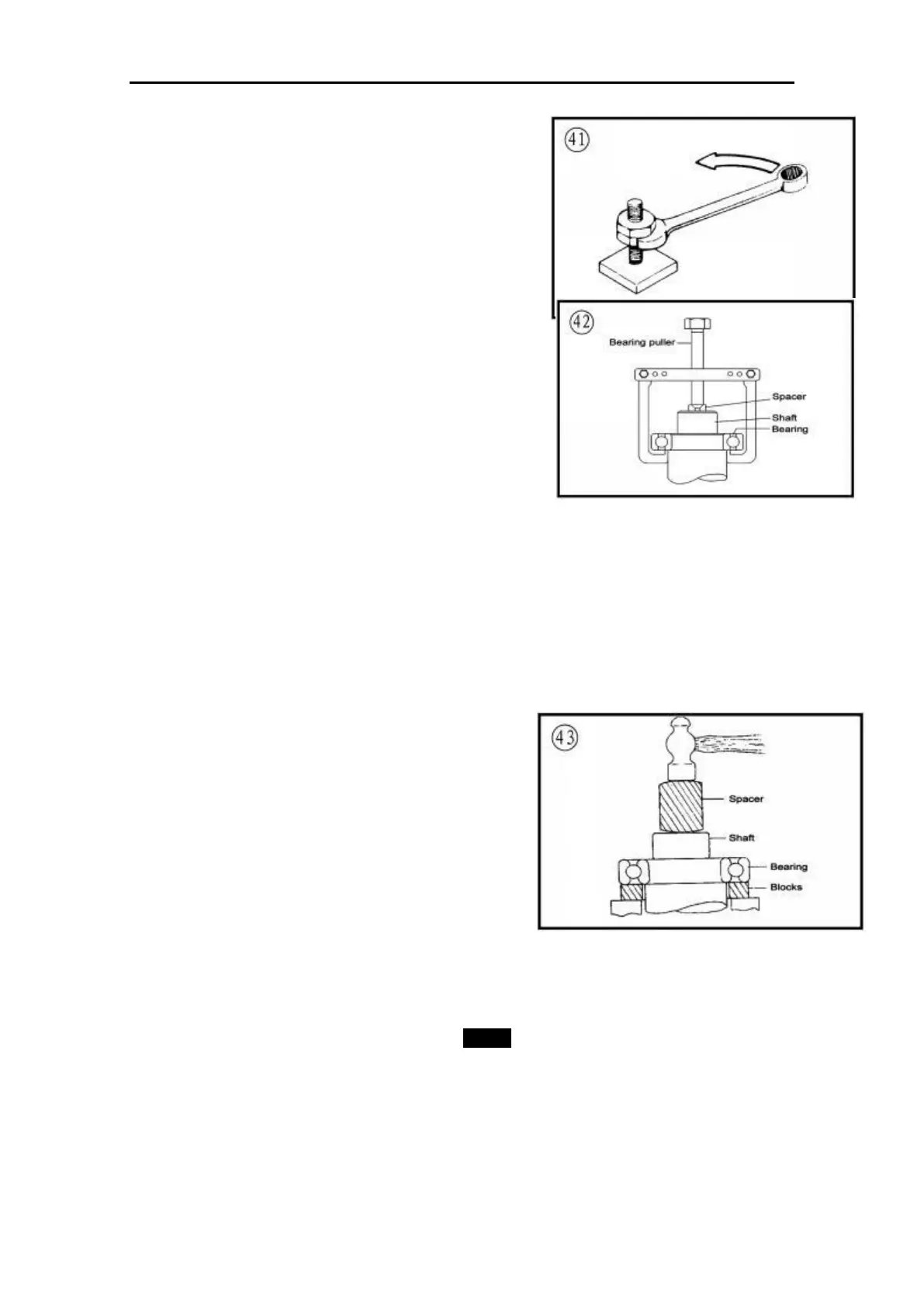

Bearings

Bearings are used in the engine and

transmission assembly to reduce power loss, heat

and noise resulting from friction. Because bearings

are precision parts, they must be maintained with

proper lubrication and maintenance. If a bearing is

damaged, replace it immediately. When installing a

new bearing, take care to prevent damaging it.

Bearing replacement procedures are included in

the individual chapters where applicable; however. Use the following sections as a

guideline.

NOTE

Unless otherwise specified, install

bearings with the manufacturer’s mark

or number facing outward.

Loading...

Loading...