OPTIONAL ATTACHMENTS AND DEVICES

13-4

M104-07-067

Check Track Sag --- every 50 hours

Swing the upperstructure 90 ° and lower the bucket to raise

the track off the ground as shown.

Keep the angle between the boom and arm 90 to 110 ° and

position the bucket’s round side on the ground. Place blocks

under the machine frame to support the machine.

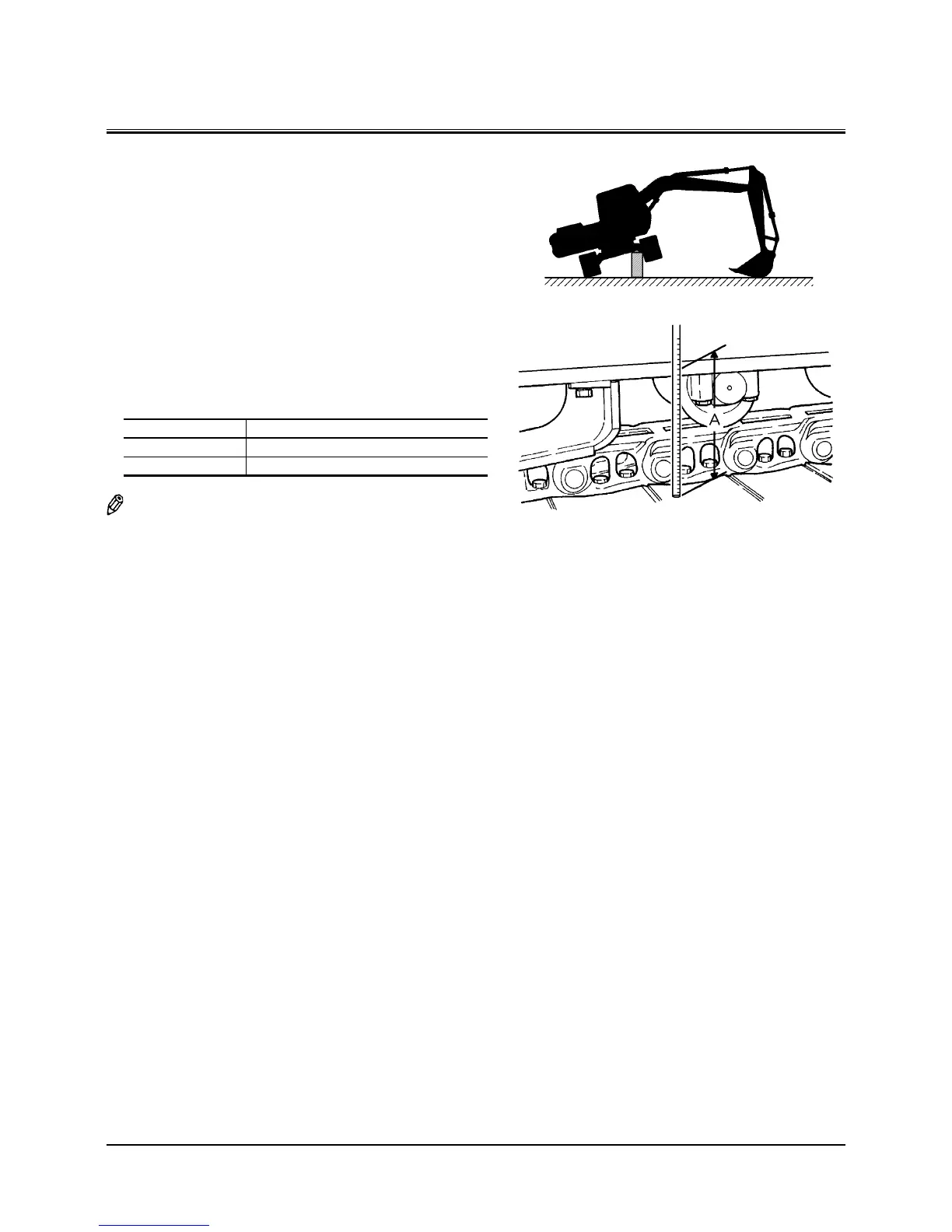

Rotate the raised track in reverse two full rotations and then

forward two full rotations.

Measure distance (A) at the middle of the track frame from

the bottom of the track frame to the back face of the track

shoe.

Track sag specifications

Model A

ZX120-3 class 250 to 280 mm (9.8 to 11.0 in)

ZX200-3 class 300 to 335 mm (11.8 to 13.2 in)

NOTE: Check track sag after thoroughly removing soil stuck

on the track area by washing.

Adjust Track Sag

Precautions for Adjusting Track Sag

1. If track sag is not within specifications, loosen or tighten

the track following the procedures shown on the next

page.

2. When adjusting track sag, lower the bucket to the ground

to raise one track off the ground. Repeat this procedure

to raise the other track. Each time, be sure to place blocks

under the machine frame to support the machine.

3. After adjusting track sag of both tracks, move the ma-

chine back and forth several times.

4. Check track sag again. If track sag is not within specifica-

tions, repeat adjustment until correct sag is obtained.

M107-07-068

Loading...

Loading...