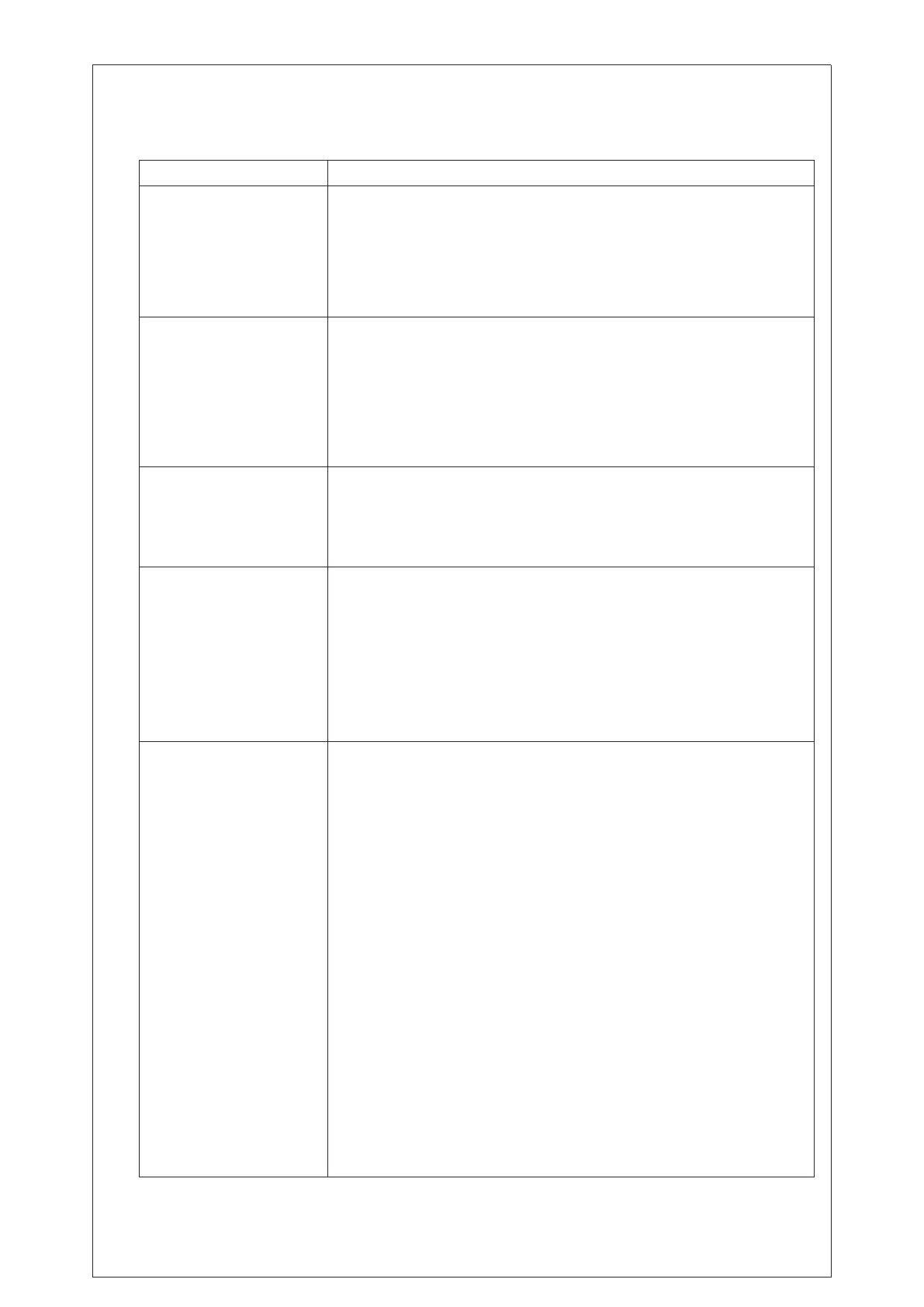

discharge "sa sa

sa" sound, no

welding output.

Abnormal

indicator light

does not light, no

high frequency

discharge "sa sa

sa" sound, "LIFT

TIG welding" can

start arc

1. The primary line of the arcing transformer has poor contact with the power board and

is retightened.

2. The discharge nozzle is oxidized or the distance is remote. The surface oxide film of

the discharge nozzle is treated or the distance of the discharge nozzle is adjusted to 1

mm.

3. The individual components of the high-frequency arc-ignition circuit are damaged,

and the replacement is found.

Abnormal

indicator light is

on, no output

1. It may be overcurrent protection. Please turn off the machine. When the abnormal

indicator light is off and then restarted, it can be restored.

2, may be overheat protection, do not need to shut down for 2-3 minutes, the machine

can naturally return to normal.

3. It may be that the inverter circuit is faulty. Please unplug the power supply plug of the

main transformer on the MOS board (near the fan VH-07 plug-in) and restart it:

(1) If the abnormality indicator is still on, turn

off the power plug of the high-frequency

pilot arc power supply (near the fan VH-03 plug-in) and turn it back on:

a. If the abnormal indicator is still on, the individual FETs on the MOS board are

damaged.

b. If the abnormal indicator is not lit, the step-up transformer in the high-frequency

arc-rising circuit on the power supply board is broken and replaced.

(2) If the abnormal indicator does not light:

a. It may be damaged in the middle plate transformer. The primary inductanc

e and Q

value of the main transformer can be measured by the bridge.

b. It may be that the transformer secondary rectifier is individually broken down, and

the same type of rectifier is found and replaced.

4. It may be that the feedback circuit is open.

Can not break the

oxide film when

welding aluminum

1. The welding gear selection is incorrect;

2. The duty cycle adjustment is too small;

3. The secondary inverter has field tube damage.

Tungsten needle

burnt seriously

The duty cycle is adjusted too much to reduce the duty cycle.

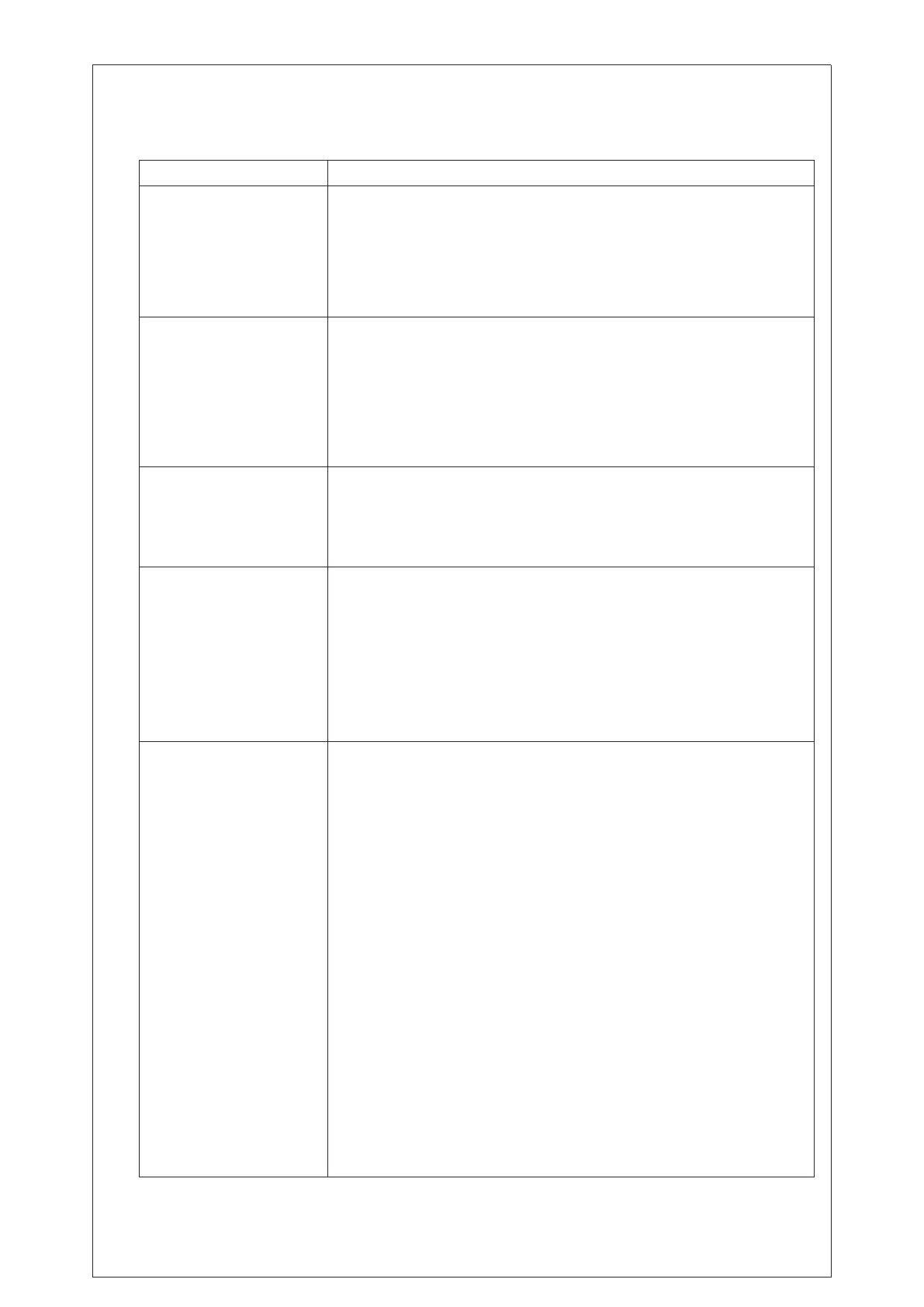

CT-520

The fan does not rotate, the

digital meter has no display,

and there is no welding

output.

1. Confirm that the air switch is intact or closed.

2. Confirm that the power grid connected to the output cable has power.

3. The thermistor (four) on the power supply board is damaged (this is usually

caused by DC24V relay failure or poor contact contact).

4. The power board (base board) is faulty and there is no DC537V voltage output.

5. The auxiliary power supply on the control panel has failed.

The fan turns, the abnormal

indicator light is not bright,

there is no high-frequency

discharge "sa sa sa" sound,

and the "LIFT TIG welding"

1. Check all kinds of patch cords in the machine for poor contact.

2. Control circuit problems, find the cause or contact the dealer.

3. The control line on the welding torch is broken.

Abnormal indicator light is off,

there is high frequency

discharge "sa sa sa" sound, no

1. The welding gun cable is broken.

2. The ground wire is broken or not connected to the welded workpiece.

3. The positive output terminal or the torch gas output terminal is loose from the

connection inside the machine.

Abnormal indicator light is not

lit, no high-frequency

discharge "sa sa sa" sound,

arc welding can start arc

1. The primary line of the arcing transformer is in poor contact with the arcing

plate and is retightened.

2. The discharge nozzle is oxidized or the dist

ance is remote. The surface of the

discharge nozzle is treated with an oxide film or the distance of the discharge

nozzle is about 1 mm.

3. Hand soldering argon welding conversion switch is damaged and replaced.

4. The individual components of the high-frequency arc-trigger circuit are

damaged, and the replacement is found.

Abnormal indicator light is on,

no output

1. It may be overcurrent protection. Please turn off the machine. When the

abnormal indicator light is off and then restarted, it can be restored.

2, may be overheat protection, do not need to shut down for 2-3 minutes, the

machine can naturally return to normal.

3. It may be that the inverter circuit is faulty. Please unplug the power supply plug

of the main transformer on the MOS board (near the fan VH-07 plug-in) and

restart it:

(1) If th

e abnormality indicator is still on, turn off the power plug of the

high-frequency pilot arc power supply (near the fan VH-03 plug-in) and turn it back

on:

a. If the abnormal indicator is still on, the individual FETs on the MOS board are

damaged.

b. If the abnormal indicator is not lit, the step-up transformer in the

high-frequency arc-rising circuit on the power supply board is broken and

replaced.

(2) If the abnormal indicator does not light:

a. It may be damaged in the middle p

late transformer. The primary inductance

and Q value of the main transformer can be measured by the bridge.

b. It may be that the transformer secondary rectifier is individually broken

down, and the same type of rectifier is found and replaced.

Loading...

Loading...