5.2.3 Attenuation parameter adjustment:When completing a section of welding and ending the

arc, in order to ensure good forming, the current is required to gradually decrease to stop. This

parameter is used to adjust the decay time of the current.

Note:When using the "foot pedal" control, this knob is turned counterclockwise to "0"

5.2.4 After flow gas time parameter adjustment:The workpiece after welding is oxidized by the

heat, so after the welding is stopped, the argo

n gas blown by the welding torch is used for a

certain period of time. This parameter is the time after the exhaust gas is adjusted, and the

maximum time can be 10 seconds.

5.2.5 In “MMA” mode,only the welding current, the hot start, arc force, and other functions do

not work.

5.3 Indicator light

Overheat protection indicator: When the welder is working continuously, for a long time or at a

high current, the overheat protection function is set to prevent damage to the device due to

internal heat. When the light is on, the digital display shows -E2, stop working, but not Shut

down, after about 2-3 minutes the device can be automatically restored.

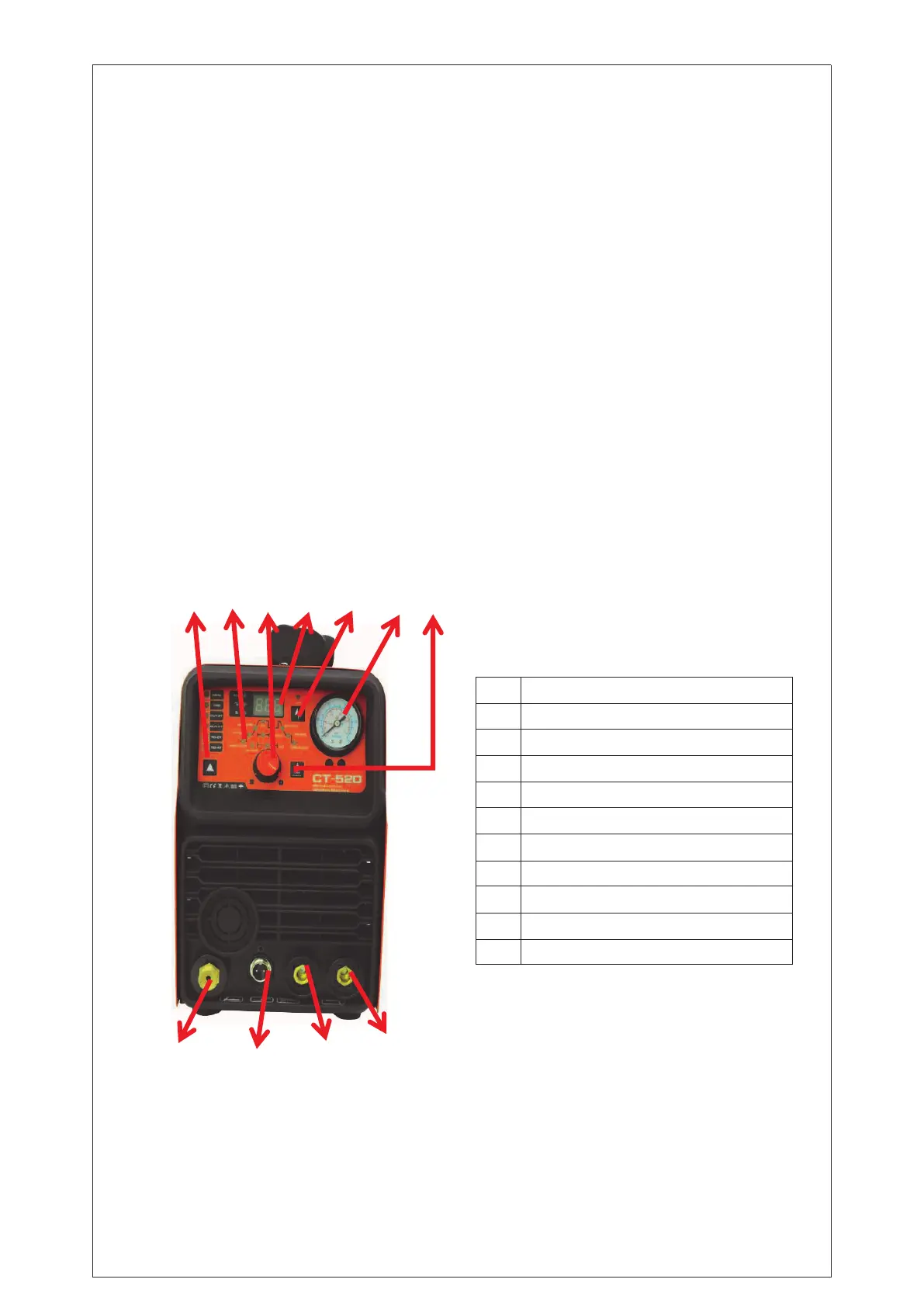

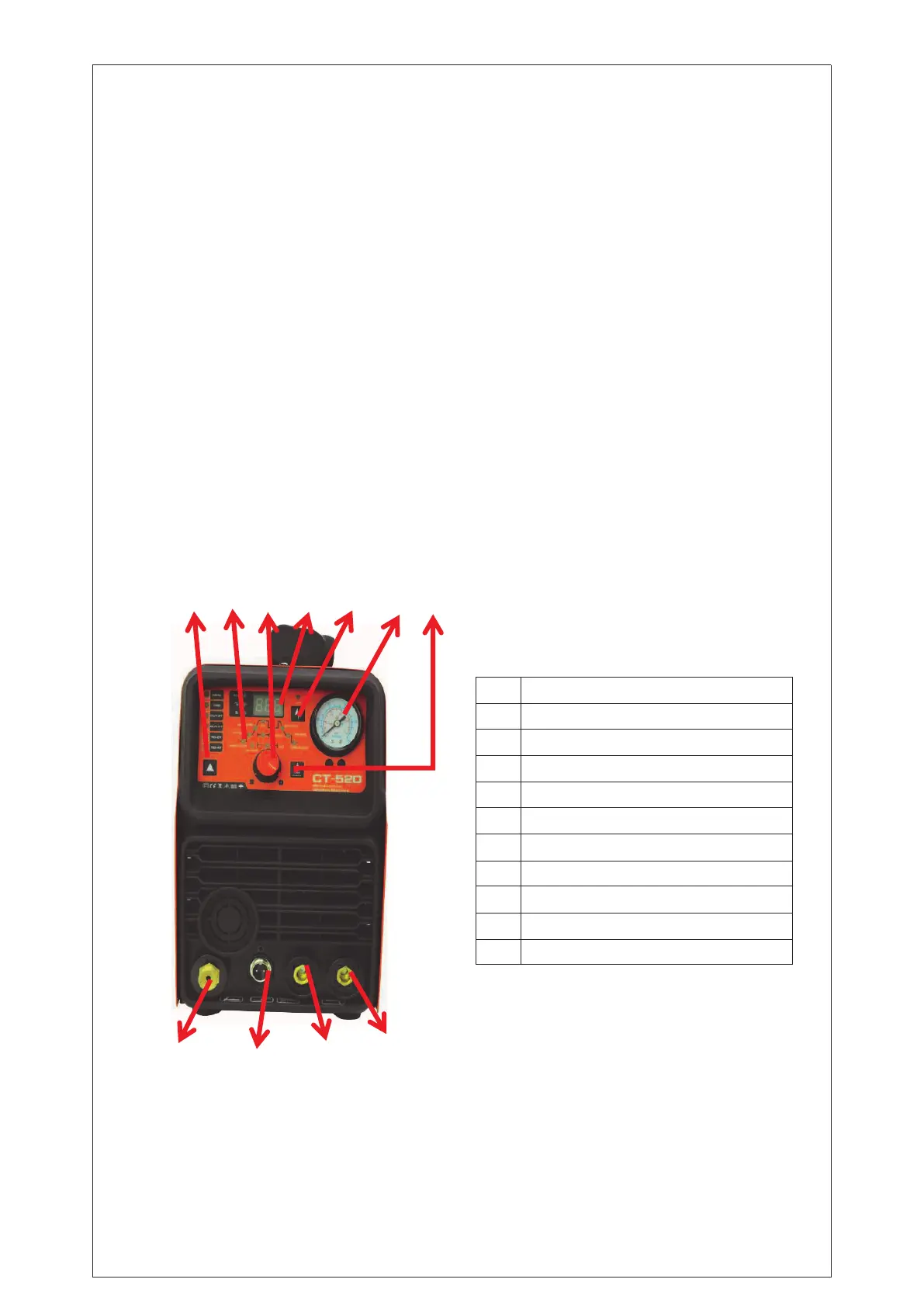

CT-520 panel schematic:

1 2 3 4 5 6 7

8 9 10 11

Welding mode selection button

Function parameter selection

Adjust knob/Confirm button

Display

High frequency button

Barometer display

Gas check button

Cutting torch/TIG torch connector

Aviation socket

10

Earth clamp connector

Electrode holder connector

Loading...

Loading...