system.

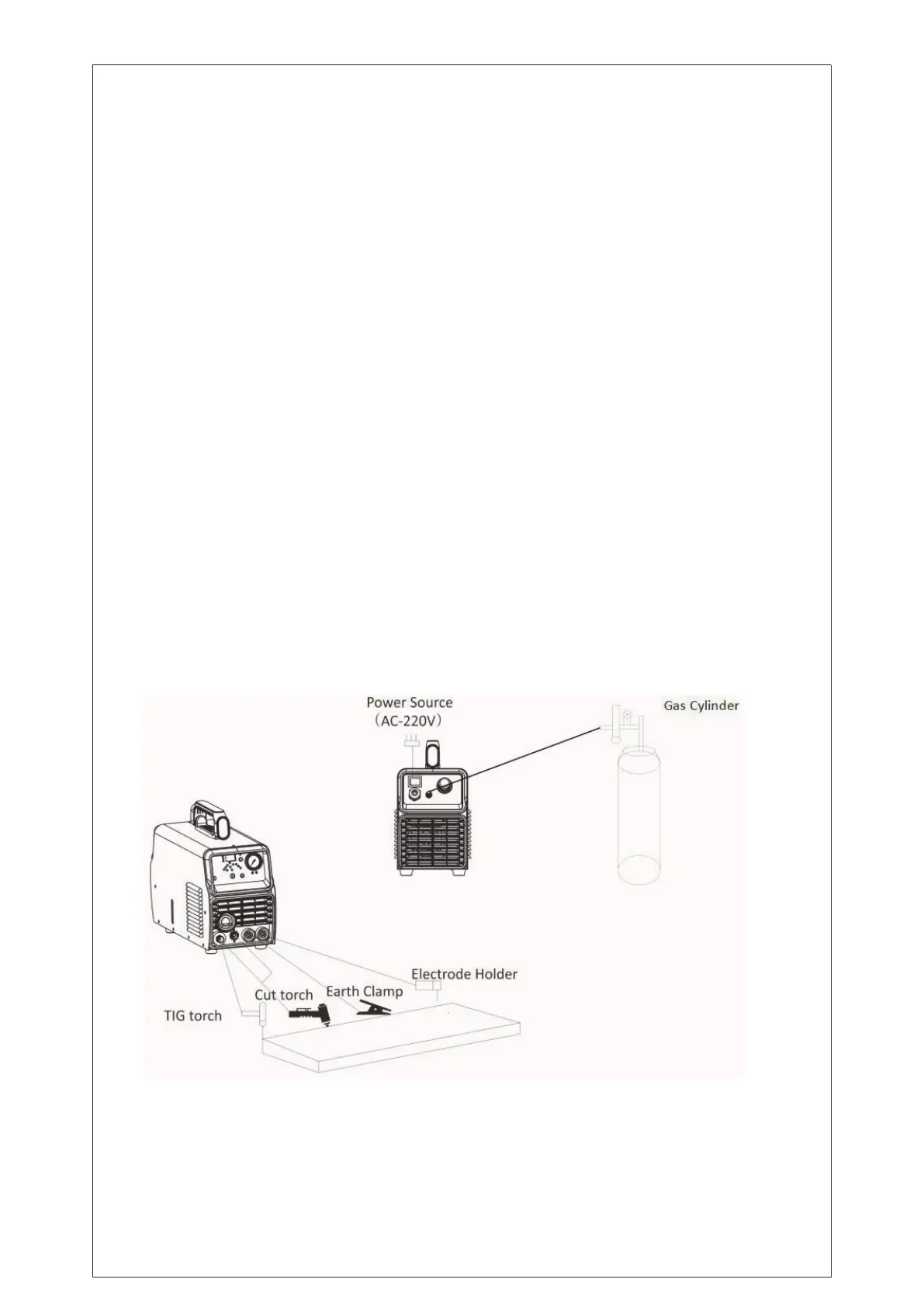

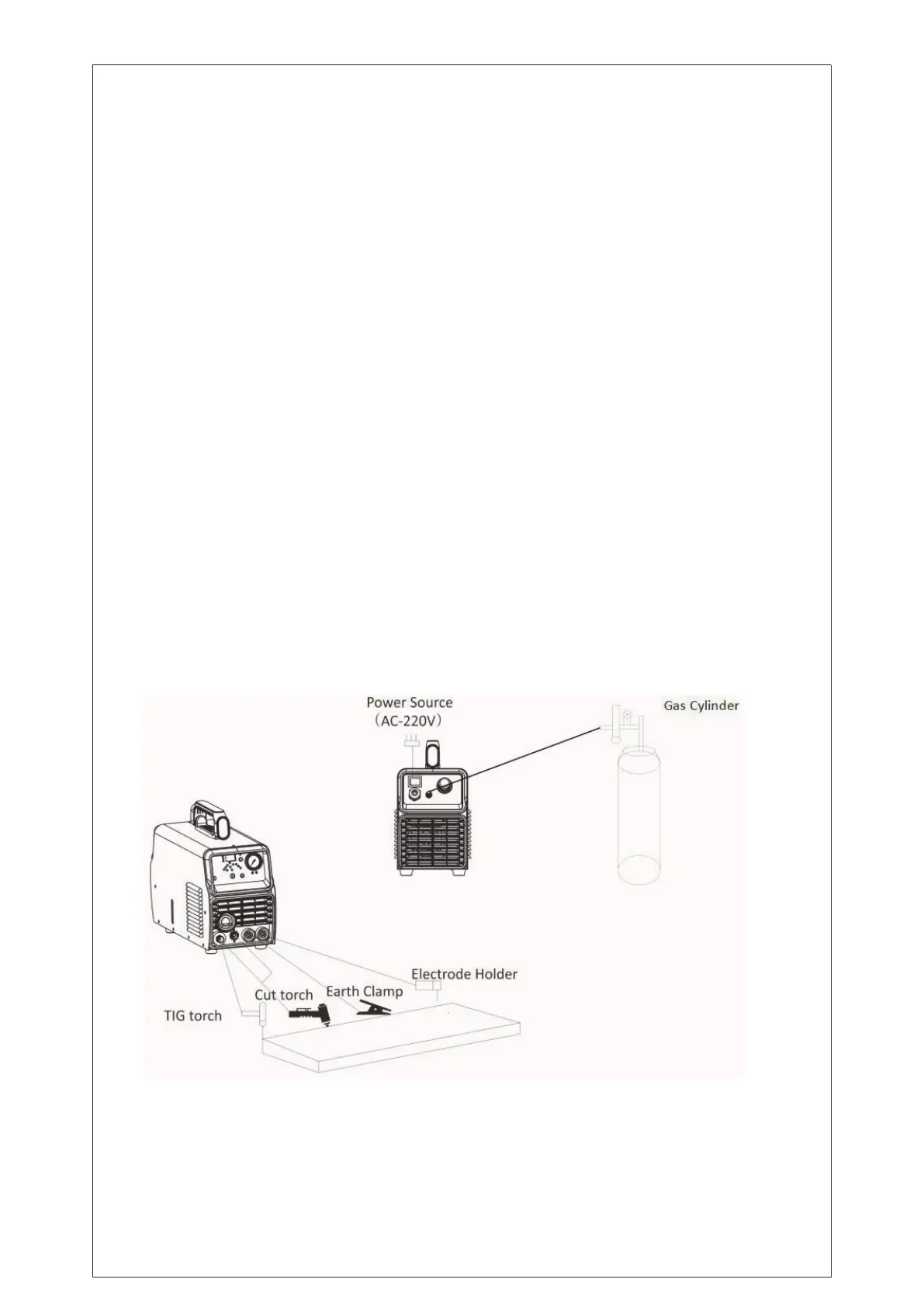

6.2 Connect the protective gas source. The gas supply passage shall include a gas cylinder, an

argon gas pressure reducing flowmeter and a gas pipe. The connecting portion of the gas pipe

shall be fastened with a hose clamp or other articles to prevent argon gas leakage and air ingress.

6.3 Ground the cables with section area no less than 6mm

2

to the housing, the way is connecting

screw in the back of the power source to ground device, or make sure ground terminal of power

s

ocket is firmly connected. Both ways can be used for absolute safety.

6.4 Plug the quick plug of the loop cable into the quick socket of the welder panel with a polarity

of "+" and follow The hour hand is tightened tightly, and the ground wire clamp at the other end

clamps the workpiece

6.5 When using the foot switch control, connect the two-core aviation and three-core aviation

plugs of the foot switch to the three-core air socket of the local panel.

6.6 According to the input volt

age level of the welding machine, connect the power line to the

distribution box of the corresponding voltage level. Do not connect the wrong voltage. Also

ensure that the error of the power supply voltage is within the allowable range.

6.7 When using manual arc welding, install the electrode holder as shown. After the above work

is completed, the welder is finished. In the installation work, welding is available.

Loading...

Loading...