9

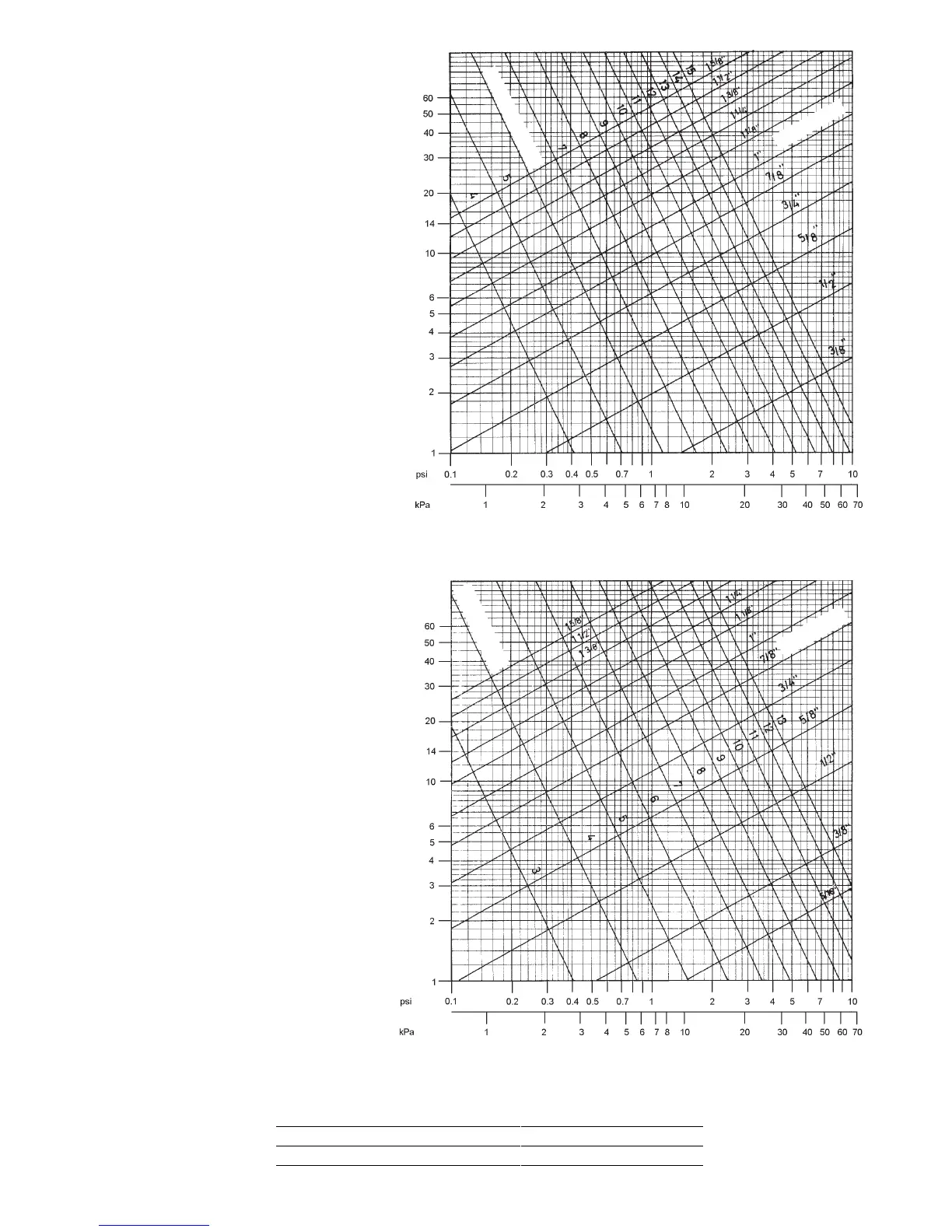

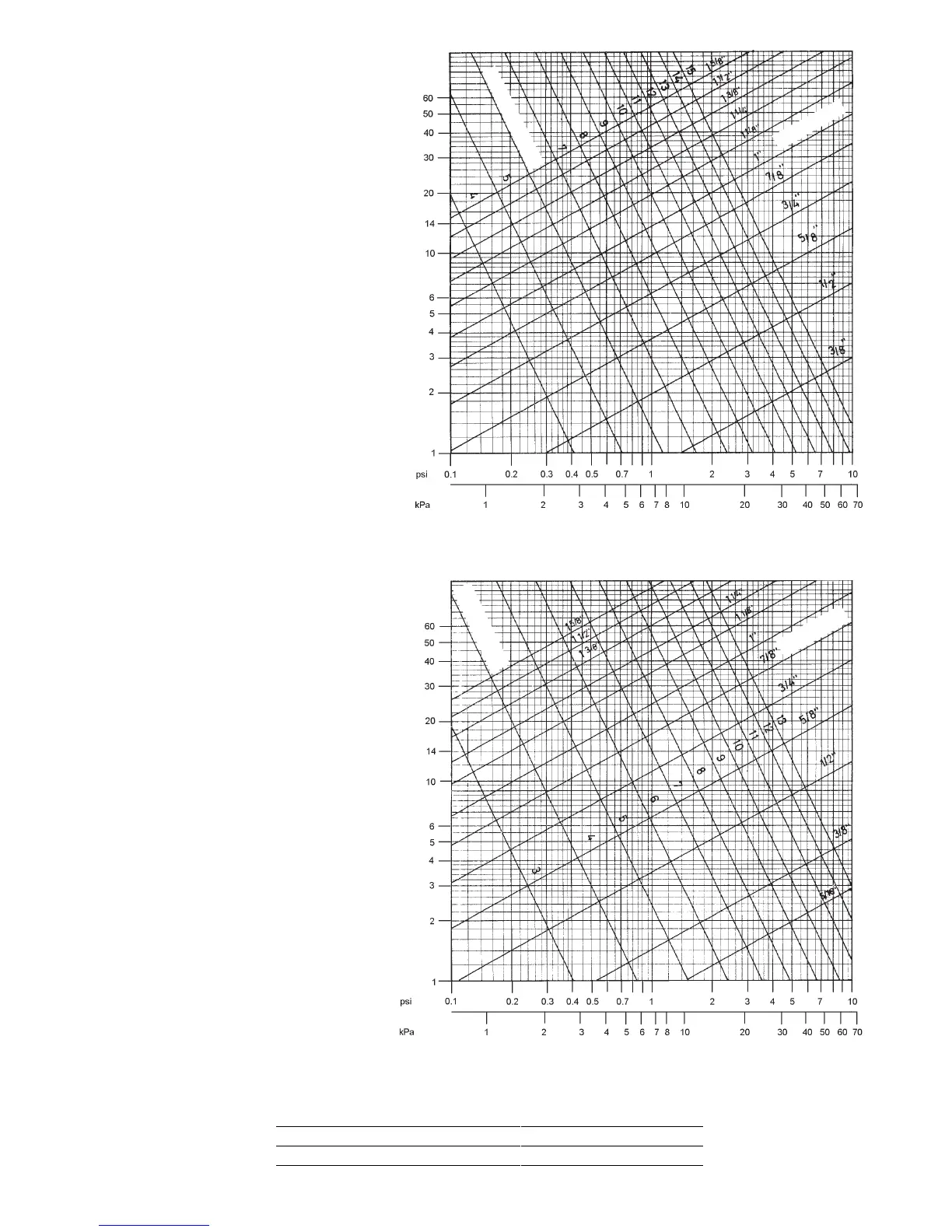

Nominal cooling capacity (kW) of one circuit

Pressure drop per 10 m. of equivalent length

Suction / discharge line. Vertical

pipe run - Fig. 3

- For heat pump systems use a trap

at the base of the vertical pipe run.

- There is no need for intermediate

trap.

- For cooling only systems traps are

not required.

- For heat pump systems keep veloc-

ity in the vertical run of suction or

discharge line more than 6 m/s.

For both options the following condi-

tions should be observed:

- The maximum allowable speed in all

gas lines is 15 m/s.

- The suction line must have insula-

tion and a slope of 1-2% toward the

compressor in the horizontal pipe

run.

- For long piping run it may be neces-

sary to adjust oil charge (see table

2). For each trap and for 10 m. of

pipe above 20 m. add oil.

- In the case of downward liquid flow

with a height exceeding 10 m. it is

necessary to install a manual pres-

sure equalization valve.

- Keep liquid subcooling at least 1°C

at the restrictor inlet. If the liquid

line has upward flow and pipe

length exceeding 15 m., for each 3.5

m. above this value provide 1°C

subcooling. In the cooling systems

subcooling can be obtained by the

contact of liquid and suction line (on

a max. length of 15 m.) creating the

heat exchange.

- For every meter of piping installed

add refrigerant according with the

table 1.

Graph 1 - Suction line

Nominal cooling capacity (kW) of one circuit

Diameter

Speed m/s

Pressure drop per 10 m. of equivalent length

Graph 2 - Discharge line

Speed m/s

Diameter

Table 2: ADDITIONAL OIL CHARGE

Diam. 3/8" 1/2" 5/8" 3/4" 7/8" 1-1/8" 1-3/8" 1-5/8"

cm³/10m 1.5 3 5 9 16 35 54 80

Loading...

Loading...