to attach wires to three (3)

Figure 2, "Current Transform

(above) to install the three (3) current transformers. Clamp a single

current transformer on each of the three (3) power wires connected

otor. The sides of the current transformers, with the white

text printed on the CT's case,

all be pointed in the same

must all be pointed in the same must

direction (CT signals in phase).

Spacing between the 3 adjacent CTs, shown in

Figure 4, "Model 610 3 Phase

connect the current transformer's

wires to the Model 610 Digital Current Monitor's CT terminals

Connect 24VAC power, as shown in

terminal to a 24 VAC source

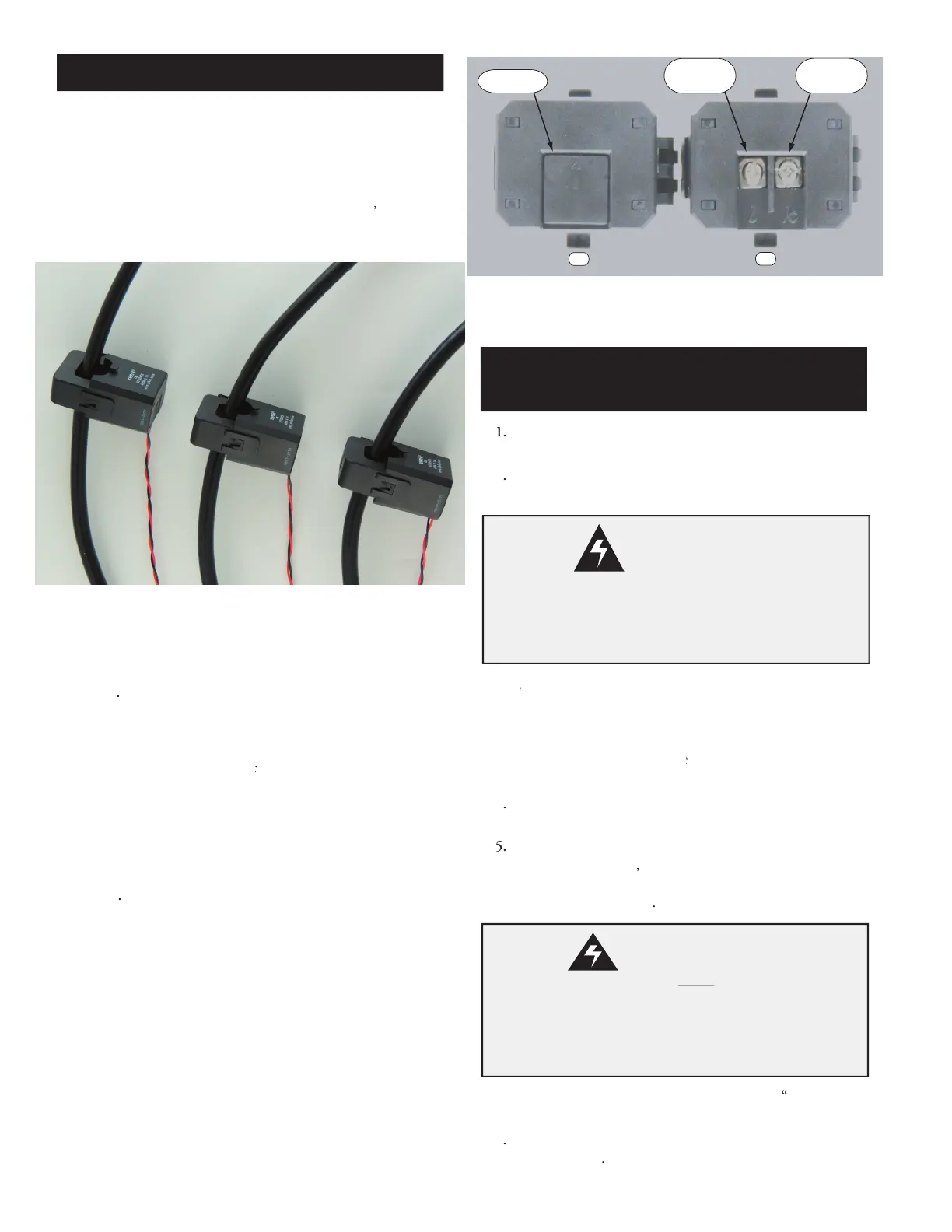

The Model 610 uses Clamp-On Current Transformers (CTs)

to monitor the current flowing through each motor's power

wire that is equipped with a current transformer. The CTs are

. When more then one (1) CT is

be oriented in the same direction, as shown in

Transformer Alignment (below)Transformer Alignment

to provide accurate in-phase

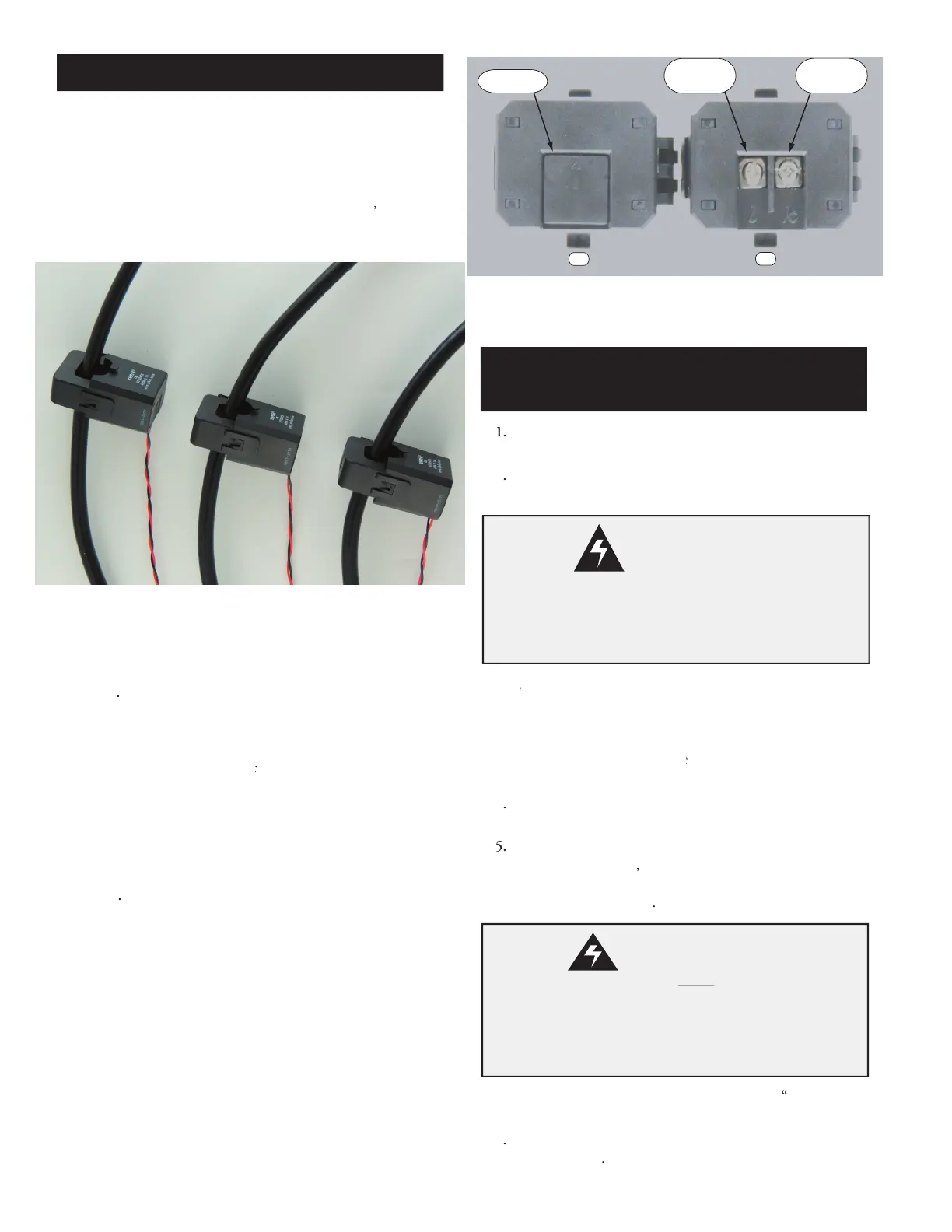

Remove plastic tab shown on CT's bottom, pictured

Figure 3A "Two Current Traneformer's Bottoms",

tab between a finger and small screw driver blade then twisting.

The tab will fly off if removed with only the screw driver blade.

required length of supplied 12 foot long required length of

twisted pair wire to reach between the CT and the Model

f additional CT wire is needed, use 22 AWG (mini-

mum) stranded, twisted pair cable properly insulated for the

application. The maximum length of additional

Attach one end of the black

Replace the plastic tab removed in sub-step

To protect 3 phase across-the-line motors, proce

Phase, Across-the-Line, Motor Installation

To protect single phase motors, proceed to the

To protect 3 phase part (split) winding motors, proce

To monitor compressor temperatures, proceed to the

pressor Temperature Sensing Information

To operate the Model 610 remotely, proceed to the

3 Phase, Across the Line,

Motor Installation

Disconnect power from the motor(s) and ensure the motor(s)

is/are electrically disabled prior to the Model 610 Digital

Current Monitor's installation.

Installation Con't

Current Transformer wires

the Model 610 Digital Current Monitor's terminal

block before operation of the motor. The Current

Transformers will generate high voltages if the wires

are left unconnected (open circuited).

Current Transformer Alignment

Two Current Transformer's Bottoms

Loading...

Loading...