SERIES 72 MODUTROL IV™ MOTORS

63-2202—46

Adapter Bracket

The 220738A Adapter Bracket, positioned between the motor

and the equipment, raises motor shaft height by 0.75 in.

(19 mm) to match that of previous Modutrol

®

Motor models.

The following applications require this bracket:

• Q607 External Auxiliary Switch.

• Damper linkage applications requiring added clearance to

allow:

— Crank arm rotation through the downward position.

— Sufficient damper linkage to reach the motor shaft.

• All valve linkages except the Q5001.

NOTE: When the bracket is not used in a replacement

application, the damper linkage requires adjustment

for the new shaft position.

To mount the motor with the bracket:

1.

Mount the bracket to the equipment with existing or

standard bolts.

2.

Using the provided bolts, mount the motor to the bracket

threaded holes. See Fig. 3.

For valve linkage applications (other than the Q5001):

1.

Mount the bracket to the linkage.

2.

Position the motor on the bracket to align the motor

shaft with the linkage.

3.

Attach the motor to the bracket with the four bolts

provided. See Fig. 4.

Damper Linkages

The motor does not include a crank arm. Order the crank arm

separately (see Accessories in the Specifications section). For

detailed instructions on the assembly of specific linkages,

refer to the Installation Instructions packed with the linkage.

CAUTION

Equipment Damage Hazard.

Stalling a motor can damage the drive shaft.

Ensure installation of motors and linkages allows the

motor to drive through full stroke without obstruction.

Valve Linkages

The Q100 Linkage requires a 220738A Adapter Bracket for all

valve applications. Applications with the Q5001 Valve Linkage

do not require the 220738A Adapter Bracket (see Fig. 4).

For detailed instructions on specific linkage assemblies, refer

to the instruction sheet packed with the linkage. In general,

check the following points when installing a motor and linkage:

• Adjust valve and louver-type damper linkages so the

damper or valve moves through only the maximum required

distance while the motor moves through its full stroke.

• With modulating control, maximum damper opening should

be no more than 60 degrees. Little additional airflow is

provided beyond this point.

• Do not exceed load and torque ratings in any application.

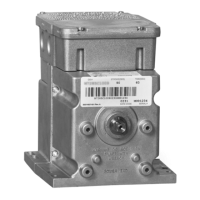

Junction Box

When used with liquid-tight conduit connectors, the junction

box provides NEMA 3 weather protection for the motor. The

junction box, standard with replacement motors, encloses the

terminals and provides knockouts for wiring conduits. Housing

an internal transformer or internal auxiliary switches requires

using a junction box.

Loading...

Loading...