SERIES 90 MODUTROL IV™ MOTORS

7 63-2631

Wiring

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

1. Ensure that the voltage and frequency stamped on the

motor correspond to the power supply characteristics.

2. When connecting several motors in parallel, ensure that

the power supply VA rating is large enough to provide

power to all motors used without overloading.

3. Fig. 9 shows that the motor terminals are

quick-connects located on top of the printed circuit

board.

4. To access the wiring compartment:

a. Remove the four screws from the junction box top.

b. Lift off the cover.

5. Refer to Fig. 5 for typical wiring, and Fig. 7 for internal

auxiliary switch connections.

NOTE: Reverse motor rotation by switching wires at either

the motor or the panel. Reverse rotation on the Series

90 models by reversing the wires at terminals W

and B.

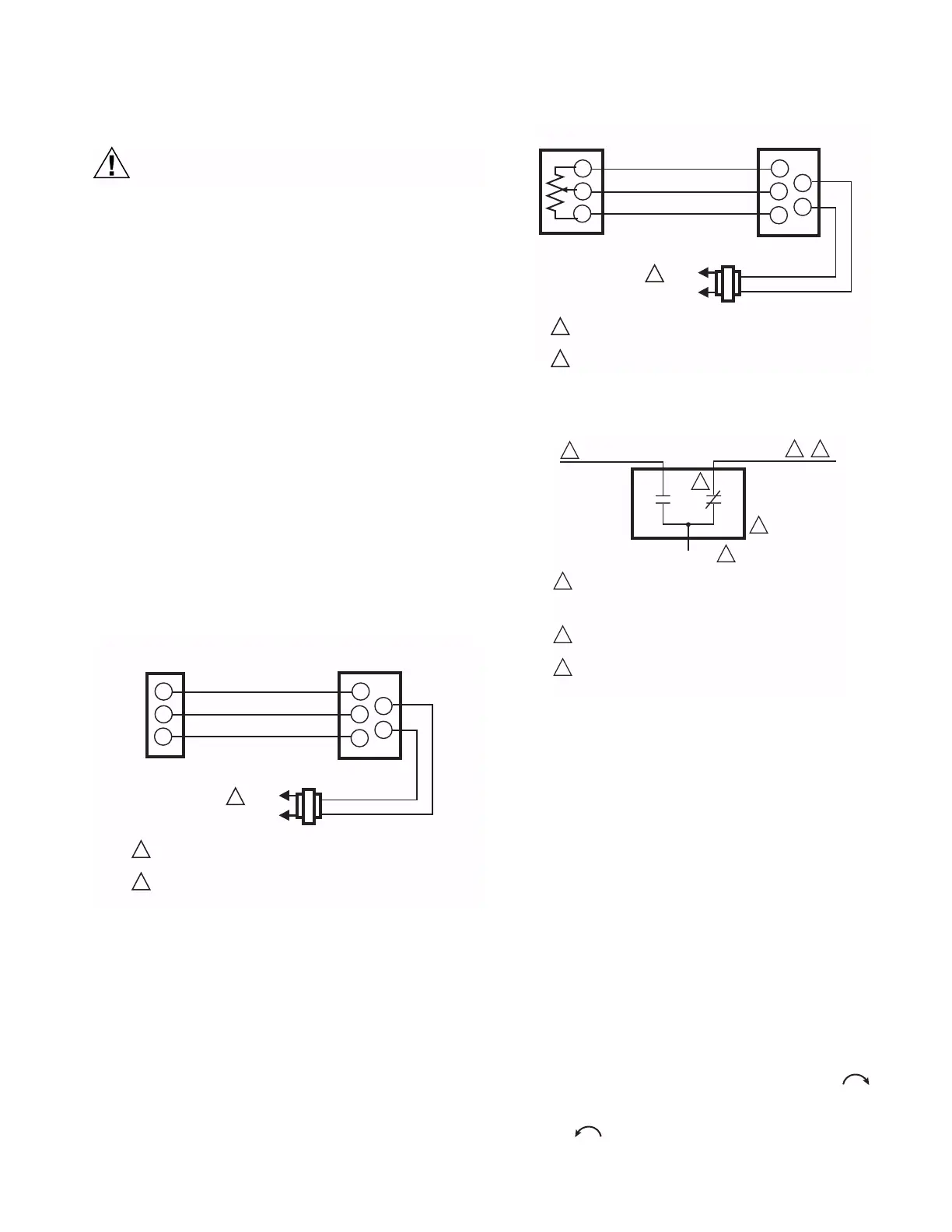

Fig. 5. Typical Series 90 wiring.

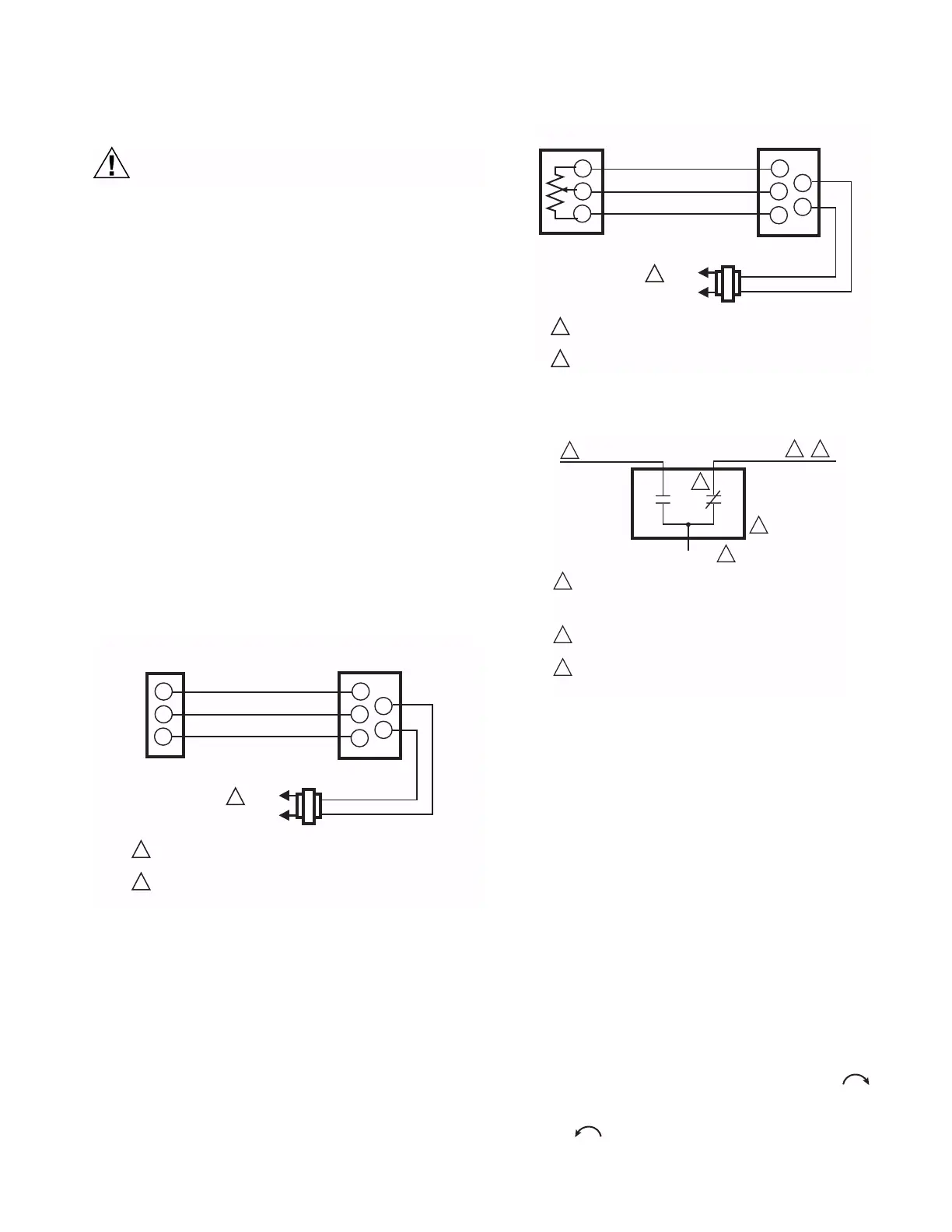

Fig. 6. Wiring for potentiometer control.

Fig. 7. Auxiliary switch schematic.

SETTINGS AND ADJUSTMENTS

Before Setting Stroke

1. Remove the top cover from the motor.

2. Disconnect the controller from the motor.

3. Connect a potentiometer to the motor as shown in Fig. 6.

IMPORTANT

Detach linkage from motor before adjusting stroke.

Adjustable Stroke

The stroke adjustment is made by means of two

potentiometers, the stroke and sensitivity potentiometers.

When viewing from the power end of the motor, the stroke

potentiometer is to the far left and sensitivity potentiometer is

to the far right (see Fig. 8). To set the stroke to 160° (maximum

position) turn the both potentiometers fully clockwise ,

using a 1/8 in. straight-blade screwdriver. To set the stroke at

90° (minimum position) turn both potentiometers fully counter-

clockwise .

L1

(HOT)

L2

1

1

2

R

W

B

R

W

B

T1

T2

TRANSFORMER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

TRANSFORMER MAY BE INTERNAL OR EXTERNAL

M770A

SERIES 90

CONTROLLER

MOTOR

L1

(HOT)

L2

1

1

2

R

W

B

R

W

B

T1

T2

TRANSFORMER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

TRANSFORMER MAY BE INTERNAL OR EXTERNAL

M13708

135 OHM

POTENTIOMETER

MOTOR

BLUE LEAD

YELLOW LEAD

RED LEAD

USE NEC CLASS 1 WIRING UNLESS POWER SUPPLY

MEETS CLASS 2 REQUIREMENTS. TAPE UNUSED LEADS.

ENSURE THE CURRENT DRAW OF THE EXTERNAL CIRCUIT

IS LESS THAN SWITCH CONTACT RATING.

ON TWO-SWITCH MOTORS, SECOND SWITCH HAS BLACK

LEADS WITH BLUE, YELLOW, AND RED TRACERS.

SOME AUXILIARY SWITCH ASSEMBLIES INCLUDE ONLY

RED AND YELLOW LEADS. SOME OTHERS DO NOT INCLUDE

THE YELLOW LEAD.

M17099

1

1

1

2

2

2

2

3

3

Loading...

Loading...