SERIES 90 MODUTROL IV™ MOTORS

9 63-2631

CAUTION

Careless Installation Hazard.

Use of excessive force while adjusting cams

damages the motor.

To avoid damaging motor end switches, set cams by

moving only the top of the screwdriver.

CAUTION

Careless Installation Hazard.

Forcibly turning the motor shaft damages the gear

train and stroke limit contacts.

Never turn motor shaft manually (by hand or with a

wrench).

CAUTION

Equipment Damage Hazard.

Can damage the motor beyond repair.

Set cams by moving the top of the screwdriver only.

Pressing screwdriver against cam slot sides or use of

excessive force can damage motor end switches.

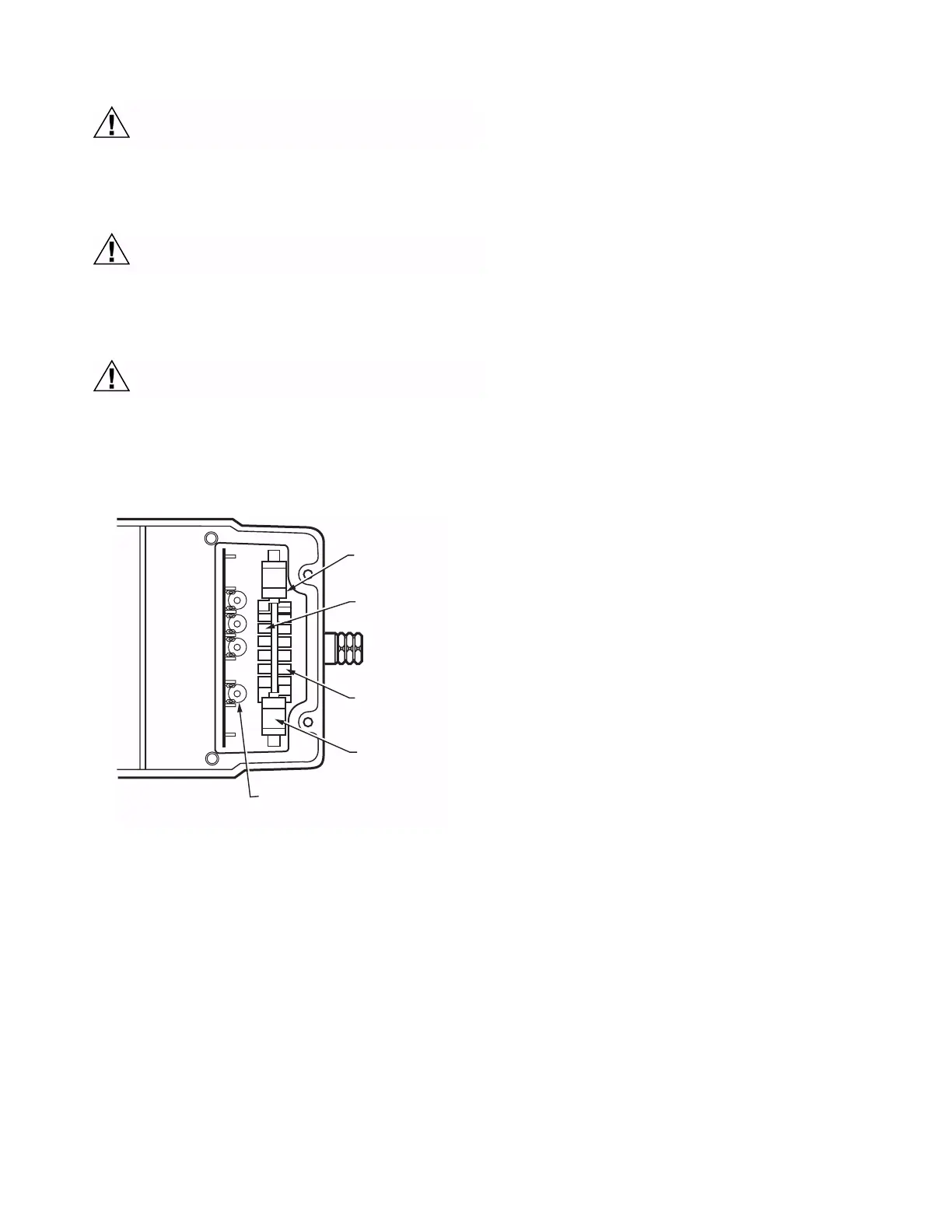

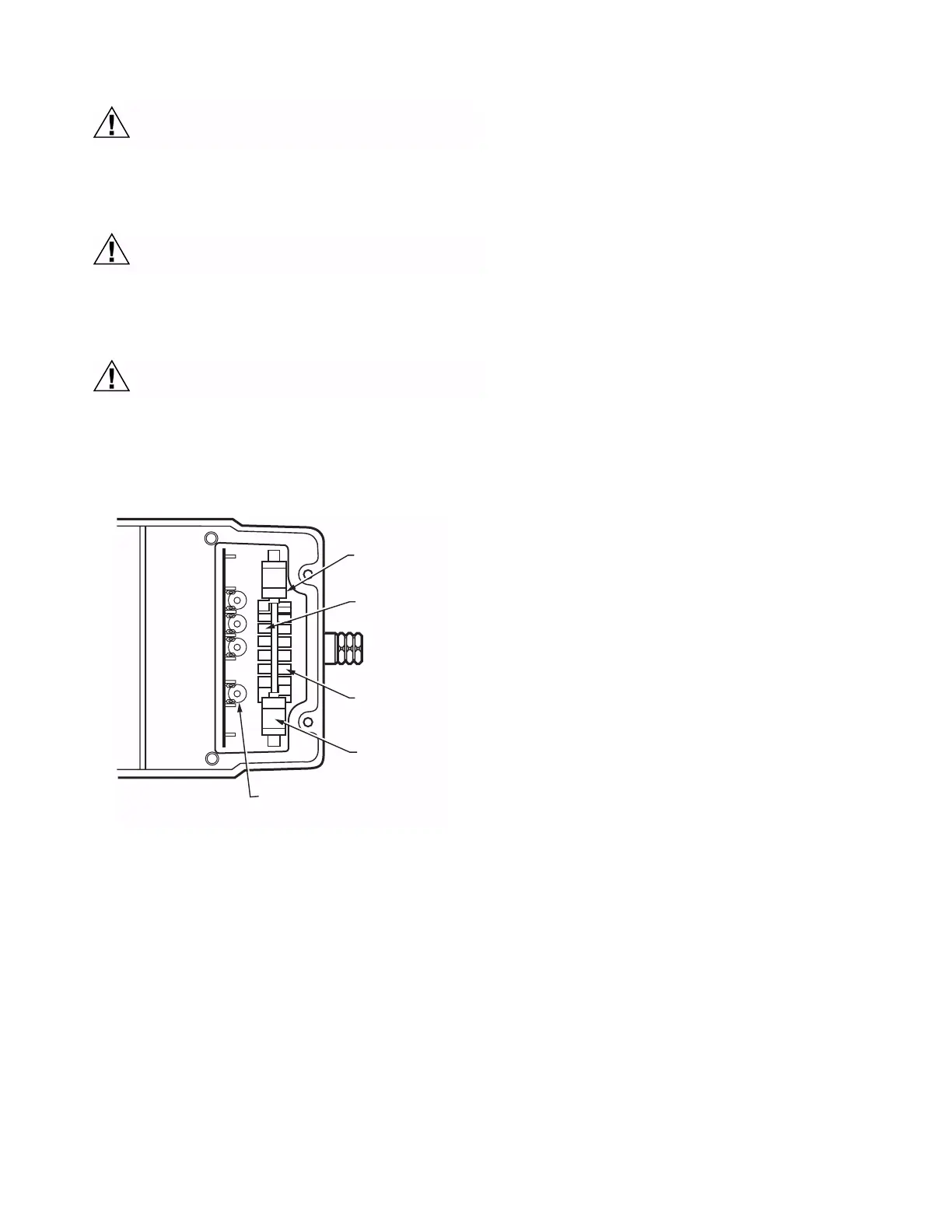

Fig. 9. Terminals and adjustments.

Auxiliary Switches

Adjustable cams actuate the auxiliary switches. These cams

can be set to actuate the switches at any angle within the

stroke of the motor. Select switch differential of 1° or 10°.

Motors with factory-added auxiliary switches are shipped in the

closed position (fully counterclockwise, as viewed from the

power end). Auxiliary cam default actuates the switches 30°

from full open with a 1° differential. With the motor in the closed

(fully counterclockwise) position, the auxiliary switch breaks

contacts R-B. See Fig. 7 (or the auxiliary switch Instruction

Sheet) for auxiliary switch wiring.

NOTE: Auxiliary switches can only be added to motors that

include auxiliary switch cams. (These cams cannot be

field-added.)

NOTE: Series 2 Motors are shipped with auxiliary switch

cams that permit acceptance of 220736A,B Internal

Auxiliary Switch Kits. Refer to Form no. 63-2228 for

220736A,B Installation Instructions.

Auxiliary Switch Adjustment

1. Remove the top cover from the motor to gain access to

the motor terminals and auxiliary cams.

2. Disconnect the controller from the motor.

3. Connect a potentiometer to the motor as shown in Fig. 6.

4. Using the potentiometer, drive the motor to the position

where the auxiliary equipment is to be switched.

5. For a 1° switch differential, check continuity of the

auxiliary switch contacts R-B and rotate the cam as

follows:

a. If the contacts are open, rotate the cam clockwise

until the R-B contacts close.

b. If the contacts are closed, rotate the cam

counterclockwise until the R-B contacts open.

6. For a 10° switch differential:

a. Spring return models: rotate the cam approximately

180° so that the slow-rise portion of the cam

actuates the switch. Then check continuity of the

auxiliary switch contacts R-B

b. Non-spring return models: check continuity of the

auxiliary switch contacts R-B.

7. Rotate the cam as follows:

a. If the contacts are open, rotate the cam

counterclockwise until the R-B contacts close.

b. If the contacts are closed, rotate the cam clockwise

until the R-B contacts open.

8. Check for proper auxiliary equipment differential and

switching by driving the motor though the full stroke in

both directions.

9. Disconnect the potentiometer, reconnect the controller,

and replace the motor top cover.

NOTE: Changing the differential from 1° to 10° reverses the

switching action. For example, with a 10° differential,

switch contacts R-B make and R-W break on a

counterclockwise (closed) rotation. With a 1°

differential, switch contacts R-W make and R-B break

on a counterclockwise (closed) rotation.

INNER AUXILIARY

SWITCH

INNER AUXILIARY

SWITCH CAM (BLUE)

POWER

END

OUTER AUXILIARY

SWITCH CAM (RED)

OUTER AUXILIARY

SWITCH

ADJUSTABLE STROKE POTENTIOMETER

NOTE: NOT ALL FEATURES AVAILABLE ON ALL MODELS.

M13707

W

B

R

T

2

T

1

Loading...

Loading...