MO953

CONVERSION

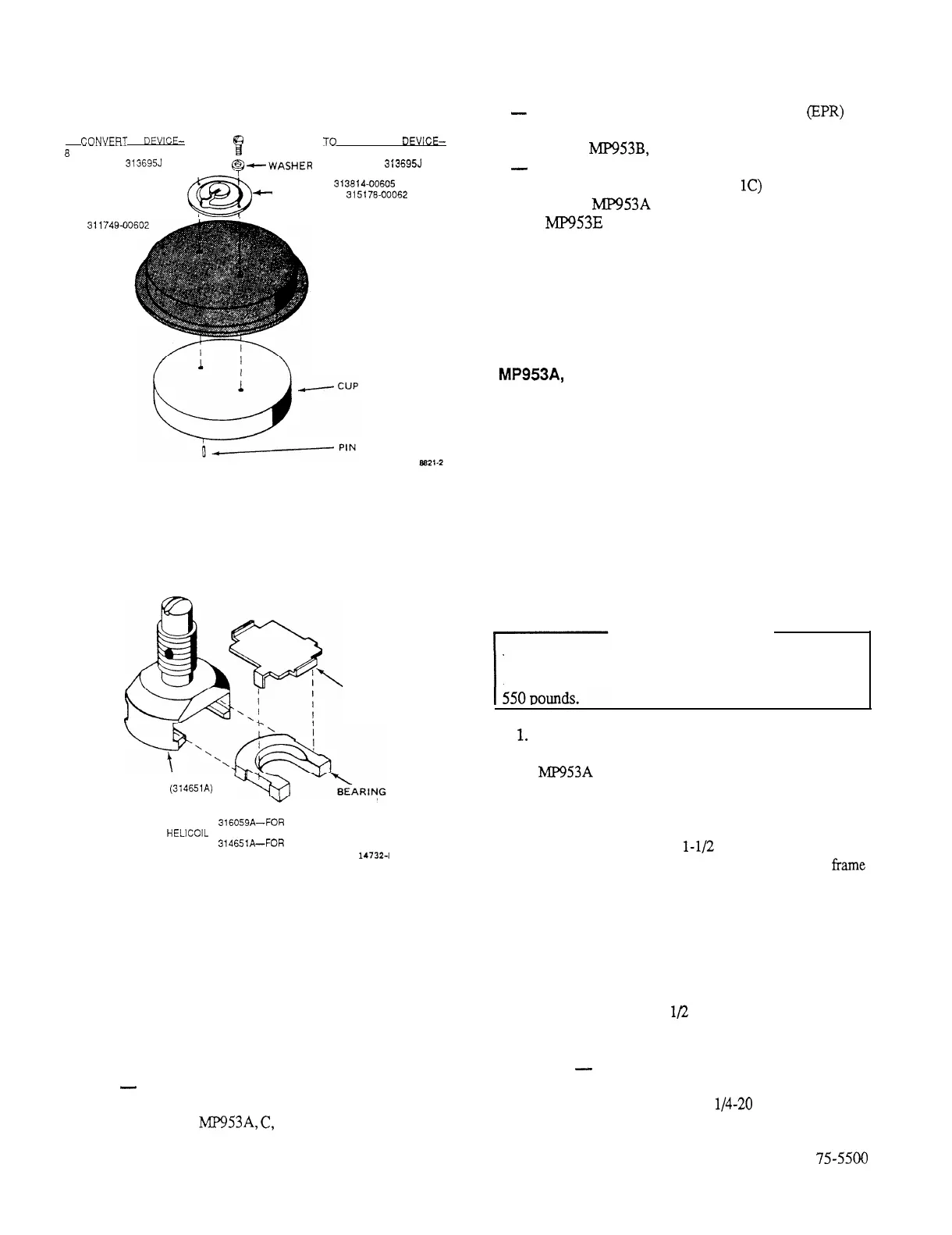

JO CONVFRT A4

DFVICF-

8

IN. (203 MM)

RELAY ASSY 313695J

FEEDBACK SPRING

3 13696-00063

CUP 315178-00062

DIAPHRAGM 311750 OR

314153

72

-SCREW

Q-WASHER

@

-

PLATE

TO CONVFRT A8

DWICF-

13 IN. (330 MM)

RELAY ASSY

313695J

FEEDBACK SPRING

313814-00605

CUP 315178-00062

DIAPHRAGM 312505

CUP 315020-00124

CUP

31174O-OO602

-DIAPHRAGM

Fig. 6. MO953 Conversion.

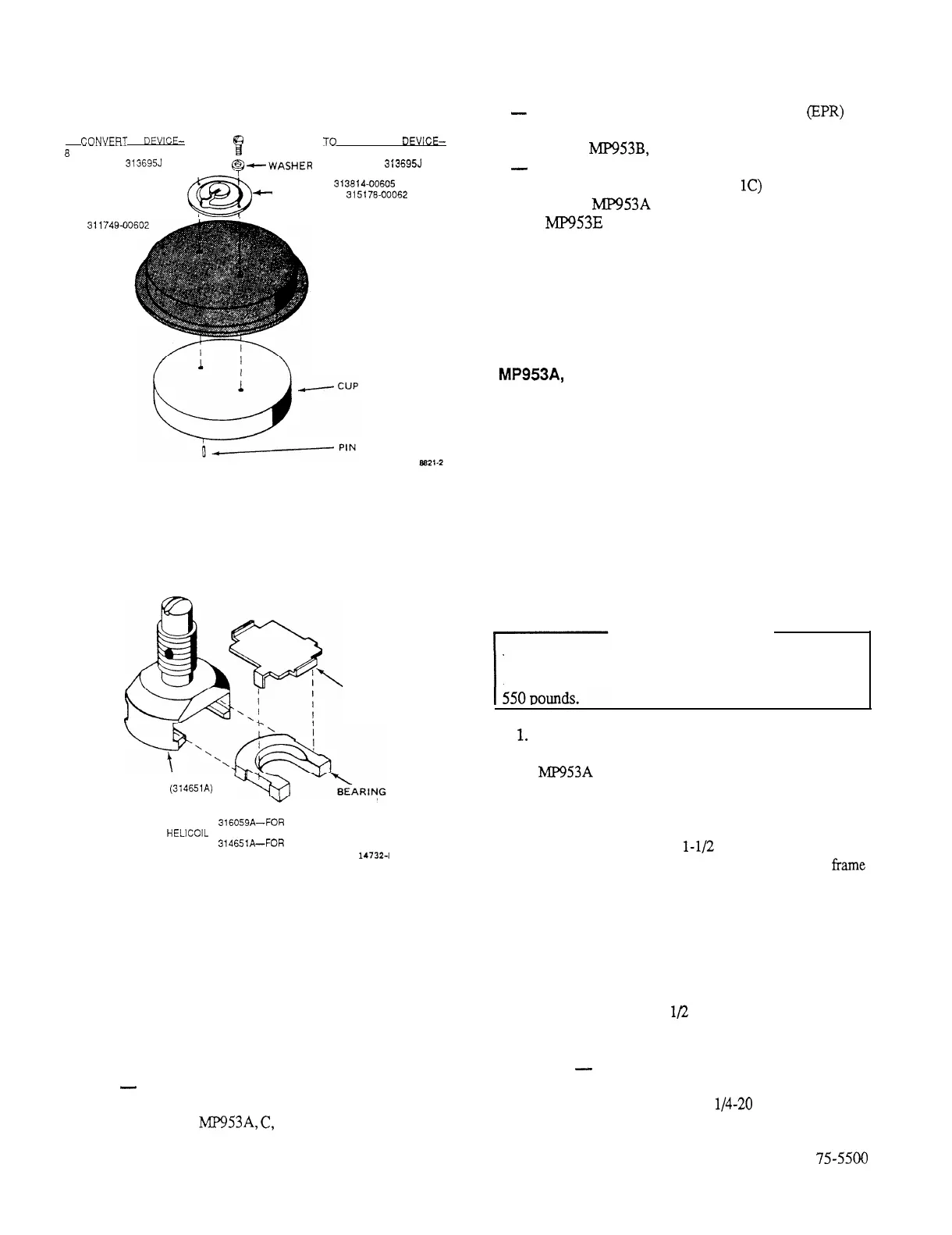

YOKE ASSEMBLY

SPRING

314652

YOKE

314651 (314651A)

316059 (316059A)

314653

ASSEMBLY

316059A-FOR

SUPPORT WITH

HELICOIL INSERT

ASSEMBLY

314651A-FOR

SUPPORT WITH

NYLON INSERT

14732-l

Fig. 7. Yoke Assembly.

REPLACE MAIN DIAPHRAGM

GENERAL

Before replacing the diaphragm, determine the type and

material of the existing diaphragm according to its color:

-

Black: Neoprene

Maximum temperature 160F (71C)

Used on

MP953A,

6,

and E

-

Black with white spot: Ethylene Propylene

(EPR)

Maximum temperature 250F (121C)

Used on

MP953B,

D and F

-

White: Silicone

Maximum temperature 250F (12

1C)

Used on

MP953A

and C and may be installed on

MP953E

Flat diaphragms and beaded-roll diaphragms are not

interchangeable. Neoprene and EPR diaphragms are

interchangeable but must meet maximum temperature

requirements.

MP953A, C, E DIRECT-ACTING ACTUATORS

Direct-acting Actuators are subject to extremely high

internal spring loads. Therefore, Actuator covers must be

removed very carefully before the the main diaphragm can

be replaced.

When using the following procedures, see Figures 8 and

10 for exploded diagrams and Tables 6 and 8 for parts.

REMOVE ACTUATOR COVER

A

WARNING

A

Use extreme caution when disassembling Actuators.

Actuator assemblies are under spring load which can reach

1.

2.

3.

4.

5.

6.

Disconnect all air lines, including any connected to

Gradutrol Relay or positive positioner, if present.

MP953A

and E only: Remove Relay/positioner from

Actuator cover by turning counterclockwise.

Remove exposed feedback spring.

See WARNING in this section. Loosen cover

setscrews sequentially

l-1/2

turns each.

Check whether cover can be squeezed back to

frame

by hand. If so, continue sequentially loosening screws

until cover is free. Remove cover, diaphragm, and go

to REPLACE DIAPHRAGM.

If cover cannot be squeezed back to frame, use the

following guides according to Actuator size.

NOTES:

a. Bolts should be threaded to within

approximately

l/2

in. of their heads.

b.

In each case, turn the long bolt in until its head

contacts the cover flange.

-

8-m Actuator: Remove two cover screws

that are directly opposite each other. Replace

cover screws with

l/4-20

x 3 in. bolts.

75-5500

Loading...

Loading...