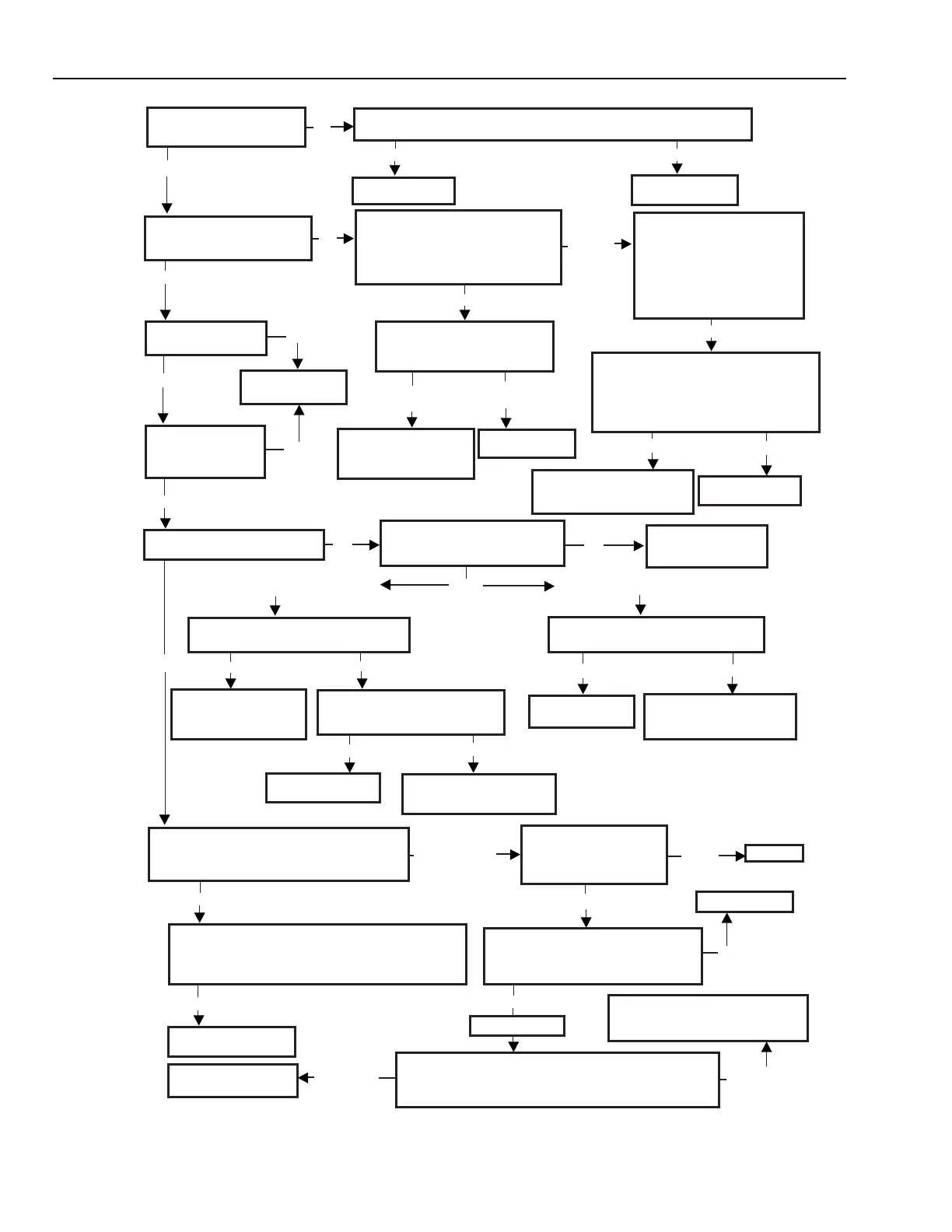

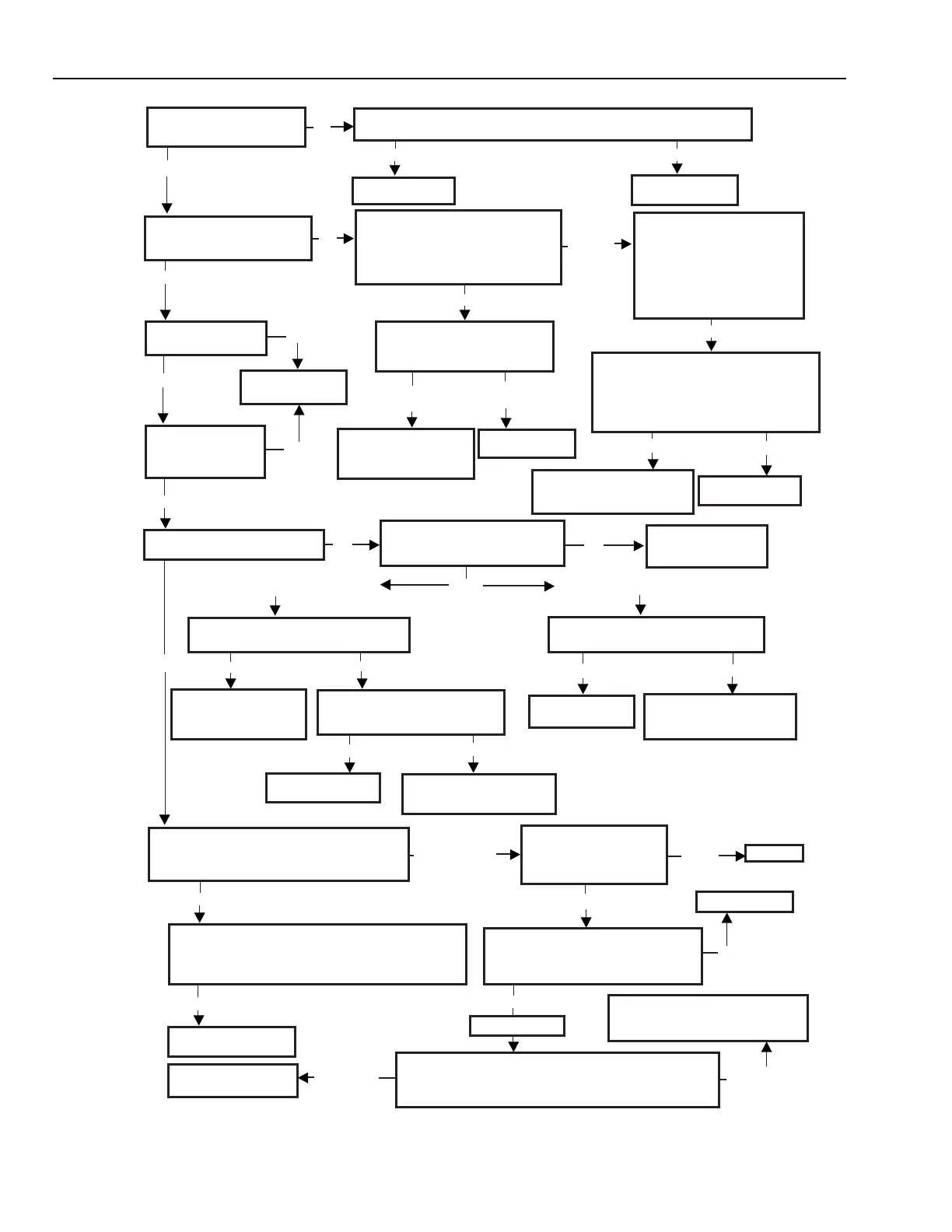

ER200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEM

68-0131—2

14

ROTATE FRESH AIR CONTROL KNOB TO MIN. PRESS

THE SYSTEM TEST BUTTON ON THE VENTILATOR

CABINET AND HOLD DOWN FOR 2 TO 4 SECONDS.

NEON TEST LAMP SHOULD BE ON DURING THIS TIME.

LEVEL 7

LEVEL 8

YES

OBSERVE FRESH AIR

CONTROL LED IS ON.

LEVEL 9

NO

LEVEL 10

ROTATE FRESH AIR

CONTROL KNOB TO

AUTO AND OBSERVE

THAT LED IS OFF.

YES

TURN POWER SWITCH AT VENTILATOR TO

OFF. DISCONNECT WIRES AT #5 AND #6

TERMINALS ON THE MASTER CONTROL

MODULE. CHECK RESISTANCE BETWEEN

THE TWO REMOVED WIRES, NOT TO BE

LESS THAN 4K OHMS.

NO

SHORT MASTER CONTROL MODULE

TERMINALS #1 AND #2 TOGETHER.

OBSERVE INCREASED AIRFLOW.

YES

USING AN OHM METER, CHECK

RESISTANCE BETWEEN EACH

OF THE TWO REMOVED WIRES

AND EACH OF THE REMAINING

WIRES AND EACH OF THE

REMAINING WIRES CONNECTING

THE FRESH AIR CONTROL.

RESISTANCE SHOULD BE

GREATER THAN 5K OHMS.

SHORT FRESH AIR CONTROL TERMINALS #1

AND #2. OBSERVE INCREASED AIRFLOW.

CONNECT POWER TO VENTILATOR. CONNECT AN AC VOLTMETER

TO MONITOR INPUT VOLTAGE TO THE VENTILATOR WHILE

DEPRESSING THE SYSTEM TEST BUTTON FOR 2 TO 4 SECONDS.

OBSERVE THAT VOLTAGE DOES NOT DROP BELOW 208 VOLTS.

YES

REPLACE TEMPERATURE

CONTROL MODULE.

VOLTAGE

ACCEPTABLE

CORRECT DEFICIENT WIRING FROM

BREAKER PANEL TO THE VENTILATOR.

HEAVIER WIRE MAY BE REQUIRED.

NO

ACTUATE DEHUMIDISTAT AND

OBSERVE INCREASED AIRFLOW.

NO

REPAIR FAULTY WIRING

BETWEEN DEHUMIDISTAT AND

MASTER CONTROL MODULE.

NO

ROTATE FRESH AIR CONTROL TO

MIN POSITION AND OBSERVE

DECREASE IN AIRFLOW.

YES

NO

ROTATE FRESH AIR CONTROL KNOB TO AUTO AND TURN

OFF DEHUMIDISTAT AND OTHER REMOTE SWITCHES. WITH

BLOWER OFF, PRESS THE SYSTEM TEST BUTTON ON THE

VENTILATOR CABINET AND HOLD DOWN FOR 2 TO 4

SECONDS. TEST LAMP SHOULD REMAIN OFF.

YES

TEST LAMP OFF

OR FLASHED ON

AND WENT OUT

NORMAL FUNCTION

CONFIRMED.

DISCONNECT POWER FROM VENTILATOR

AND UNPLUG HEATER USING AN OHM

METER. VERIFY RESISTANCE TO BE

BETWEEN 15 AND 25 OHMS.

YES

LEVEL 6

CORRECT FAULTY WIRING

BETWEEN FRESH AIR

CONTROL AND MASTER

CONTROL MODULE.

REPLACE FRESH

AIR CONTROL.

CORRECT FAULTY WIRING

BETWEEN FRESH AIR CONTROL

AND MASTER CONTROL MODULE.

REPLACE FRESH

AIR CONTROL.

REPLACE MASTER

CONTROL MODULE IN

VENTILATOR CABINET.

REMOVE SHORT FROM TERMINALS

#1 AND #2 AT DEHUMIDISTAT AND

OBSERVE INCREASED AIRFLOW.

LOW VOLTAGE

CONFIRMED

REPLACE HEATER

FAULT

FOUND

CORRECT

NO FAULT FOUND

REPLACE FAULTY

DEHUMIDISTAT.

PLUG IN HEATER

YES

GREATER

THAN 4K

OHMS.

DISCONNECT ALL WIRES AT FRESH AIR

CONTROL AND PREVENT FROM SHORTING.

CHECK RESISTANCE BETWEEN WIRES

REMOVED FROM MASTER CONTROL MODULE

TERMINALS #5 AND #6. RESISTANCE SHOULD

BE GREATER THAN 6K OHMS.

NO

REPLACE FRESH

AIR CONTROL.

NO

LESS THAN

5K OHMS

DISCONNECT OTHER END OF

THESE SAME WIRES AT THE FRESH

AIR CONTROL AND CHECK

RESISTANCE BETWEEN THEM.

GREATER

THAN 5K OHMS

YES

VERIFY HEATER AND

MASTER CONTROL MODULE

CONNECTORS ARE

PLUGGED IN PROPERLY

REPAIR FAULTY WIRING

BETWEEN FRESH AIR

CONTROL AND MASTER

CONTROL MODULE.

SHORT HUMIDISTAT TERMINAL #1 AND #2

AND OBSERVE INCREASED AIRFLOW.

WITH DEHUMIDISTAT CONNECTED DIRECTLY

TO MASTER CONTROL MODULE.

WITH DEHUMIDISTAT CONNECTED

TO FRESH AIR CONTROL.

YES

NO

YES

NO

REPAIR FAULTY WIRING

BETWEEN DEHUMIDISTAT AND

FRESH AIR CONTROL.

REPLACE FAULTY

DEHUMIDISTAT.

YES

NO

LESS THAN 4K OHMS.

ER200A1018 ONLY

LEVEL 5

PLACE RANGE SWITCH IN LOW

POSITION AND OBSERVE

DECREASED AIRFLOW

YES

DISCONNECT HI-SPEED OVERRIDE DEVICE FROM TERMINALS #1 AND #2 AT DEVICE

(TIMER, DEHUMIDISTAT, ETC.) AND AT VENTILATOR MASTER CONTROL MODULE.

REPLACE MASTER

CONTROL MODULE.

NO

NO DECREASE BLOWER RUNS

DECREASE OBSERVED

CORRECT SHORTED

WIRING OR DEVICE.

M5308A

Fig. 13. ER200 system check and troubleshooting procedures for Levels 5 through 10.

Loading...

Loading...