44 ซ.บรมราชชนนี 70 ถ.บรมราชชนนี ศาลาธรรมสพน์ ทวีวัฒนา กทม. 10170.

Website: https://www.add-furnace.com/ โทร: 02-888-3472

Line ID: @add11 e-mail: add028883472@gmail.com

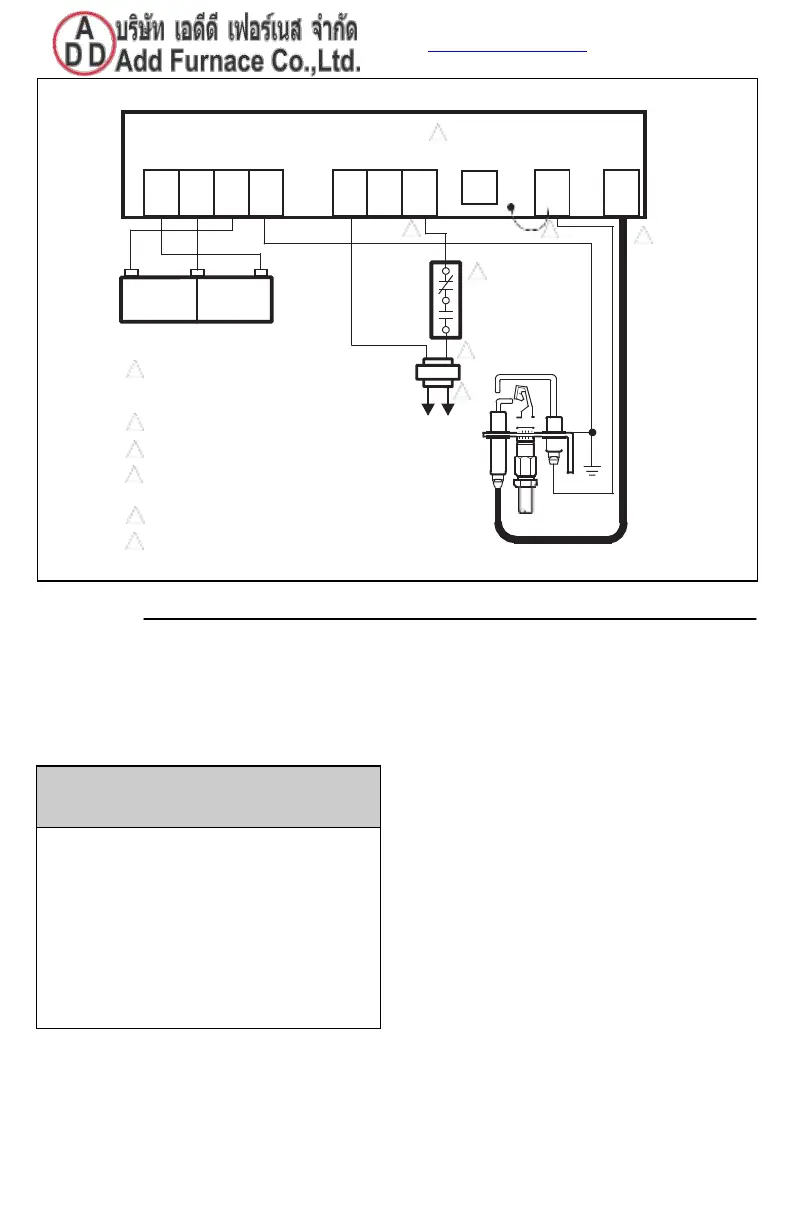

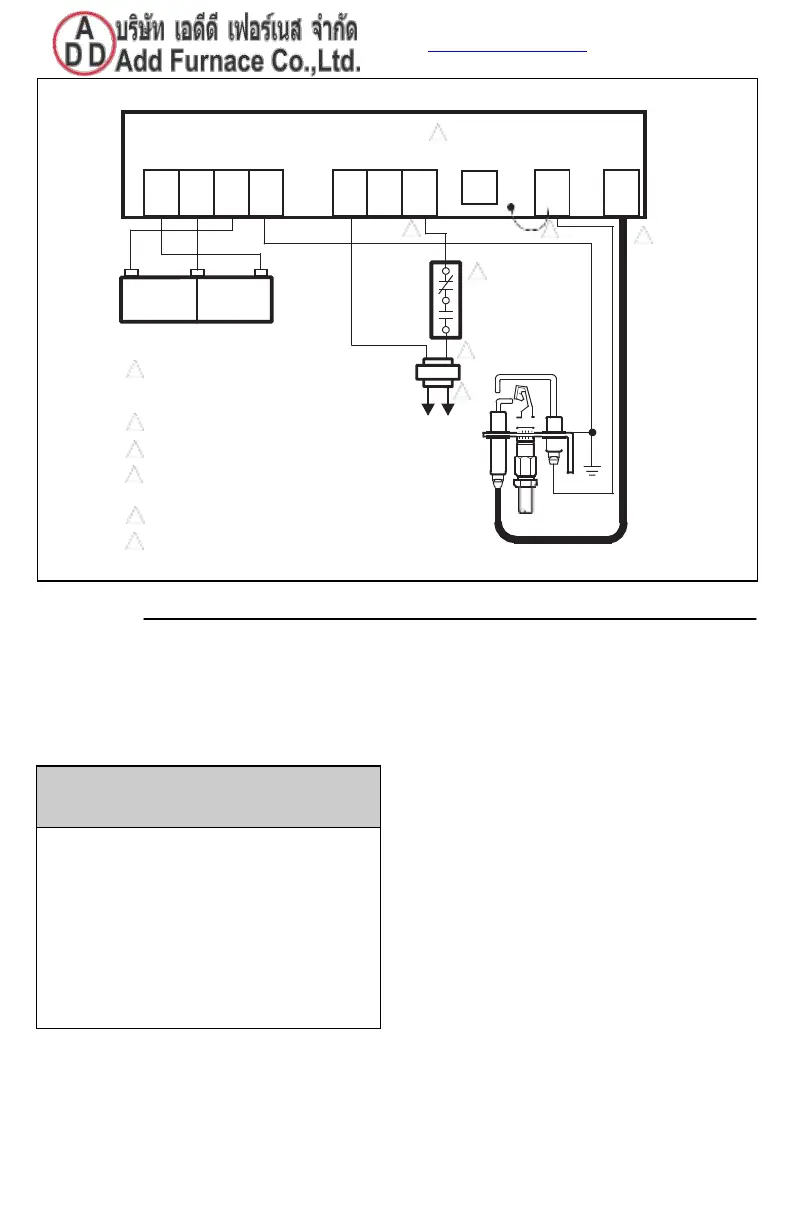

Fig. 10—S8600F,H,M; S8610F,H; S8660D; S8670D connections in a commercial water heater control system.

CHECKOUT

Check out the gas control system:

•

At initial installation of the appliance.

•

As part of regular maintenance procedures. Mainte-

nance intervals are determined by the application.

See PLANNING THE INSTALLATION, page 1, for

more information.

•

As the first step in troubleshooting.

•

Any time work is done on the system.

STEP 1: Perform Visual Inspection.

❏

With power off, make sure all wiring connections are

clean and tight.

❏

Turn on power to appliance and ignition module.

❏

Open manual shutoff valves in the gas line to the

appliance.

❏

Do gas leak test ahead of gas control if piping has been

disturbed.

GAS LEAK TEST: Paint pipe joints with rich soap and water

solution. Bubbles indicate gas leak. Tighten joints to stop

leak. Recheck with soap and water.

STEP 2: Review Normal Operating Sequence and Module

Specifications.

❏

See OPERATION, page 12, and APPLICATION,

page 1.

STEP 3: Reset the Module.

❏

Turn the thermostat to its lowest setting.

❏

Wait one minute.

As you do Steps 4 and 5, watch for points where operation

deviates from normal. Refer to Troubleshooting Chart to

correct problem.

STEP 4: Check Safety Shutoff Operation.

This step applies to lockout and continuous retry modules

only.

❏

Turn gas supply off.

❏

Set thermostat or controller above room temperature to

call for heat.

❏

Watch for spark at pilot burner either immediately or

following prepurge. See device label.

❏

Time spark from start to shutoff. See device label.

On S8600M, wait 6 min. nom. Ignition sequence should

start again followed by shutoff after 90 sec. max.

❏

Open manual gas cock and make sure no gas is flowing

to pilot or main burner.

❏

Set thermostat below room temperature and wait one

minute before continuing.

STEP 5: Check Normal Operation.

❏

Set thermostat or controller above room temperature to

3

MAXIMUM CABLE LENGTH 3 ft [0.9 m].

4 CONTROLS IN 24V CIRCUIT MUST NOT BE IN

GROUND LEG TO TRANSFORMER.

5 DO NOT REMOVE VENT DAMPER PLUG.

6 REMOVE JUMPER AND CONNECT SENSE

TERMINAL ON TWO ROD APPLICATION ONLY.

1

POWER SUPPLY. PROVIDE DISCONNECT

MEANS AND OVERLOAD PROTECTION AS

REQUIRED.

2

ALTERNATE LIMIT CONTROLLER LOCATION.

DUAL VALVE COMBINATION

GAS CONTROL

FAILURE TO HEED THESE WARNINGS MAY

CAUSE FIRE OR EXPLOSION WITH PROPERTY

DAMAGE, INJURY, OR LOSS OF LIFE.

1.

If you smell gas or suspect a gas leak, turn off

gas at manual service valve and evacuate the

building. Do not try to light any appliance, do

not touch any electrical switch or telephone in

the building until you are sure no spilled gas

remains.

2.

Gas leak test must be done as described in

Steps 1 and 5 below on initial installation and

any time work is done involving the gas pip-

ing.

Loading...

Loading...