T775A/B/M SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

62-0254—13 22

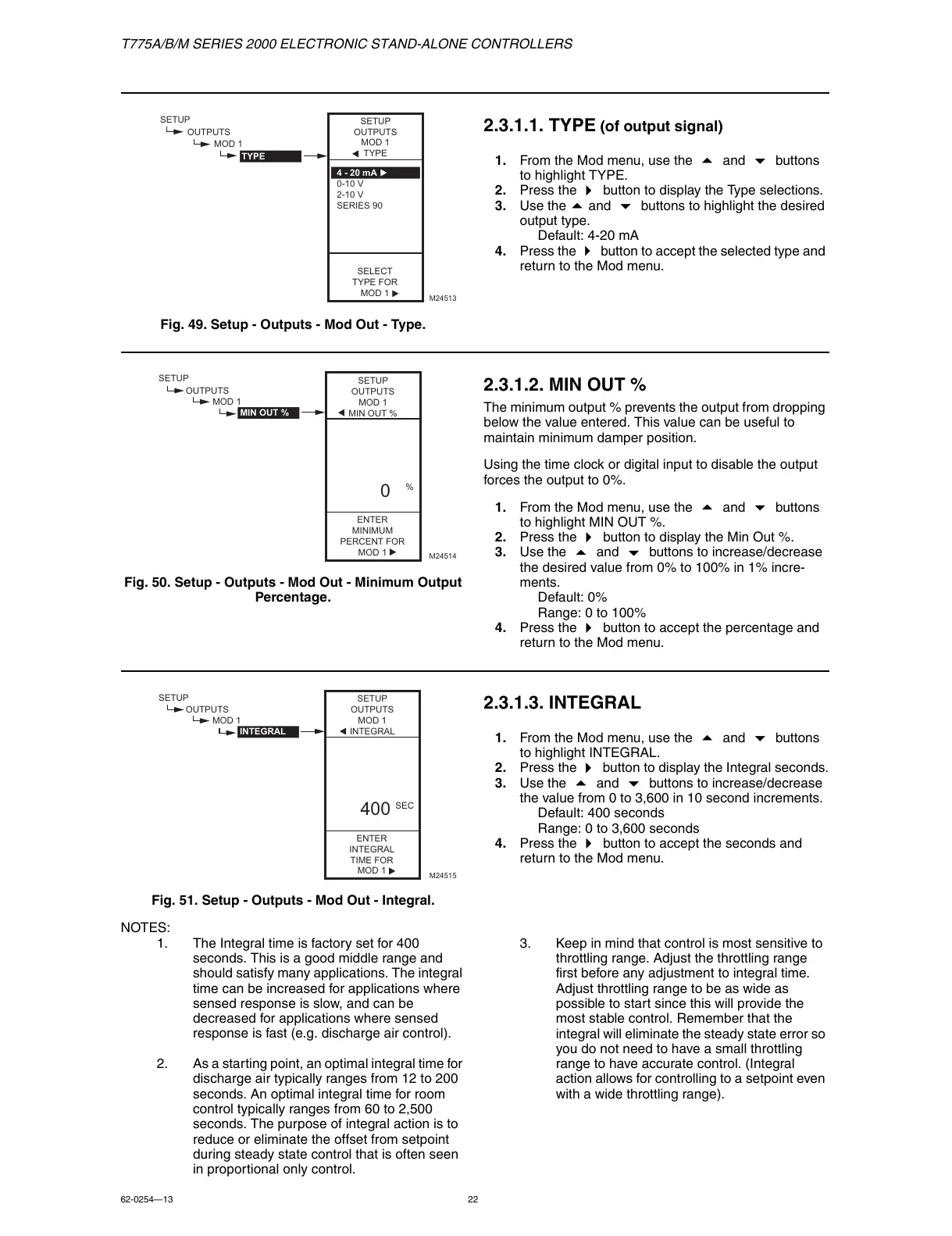

Fig. 49. Setup - Outputs - Mod Out - Type.

2.3.1.1. TYPE (of output signal)

1. From the Mod menu, use the and buttons

to highlight TYPE.

2. Press the

button to display the Type selections.

3. Use the

and buttons to highlight the desired

output type.

Default: 4-20 mA

4. Press the

button to accept the selected type and

return to the Mod menu.

Fig. 50. Setup - Outputs - Mod Out - Minimum Output

Percentage.

2.3.1.2. MIN OUT %

The minimum output % prevents the output from dropping

below the value entered. This value can be useful to

maintain minimum damper position.

Using the time clock or digital input to disable the output

forces the output to 0%.

1. From the Mod menu, use the

and buttons

to highlight MIN OUT %.

2. Press the

button to display the Min Out %.

3. Use the

and buttons to increase/decrease

the desired value from 0% to 100% in 1% incre-

ments.

Default: 0%

Range: 0 to 100%

4. Press the

button to accept the percentage and

return to the Mod menu.

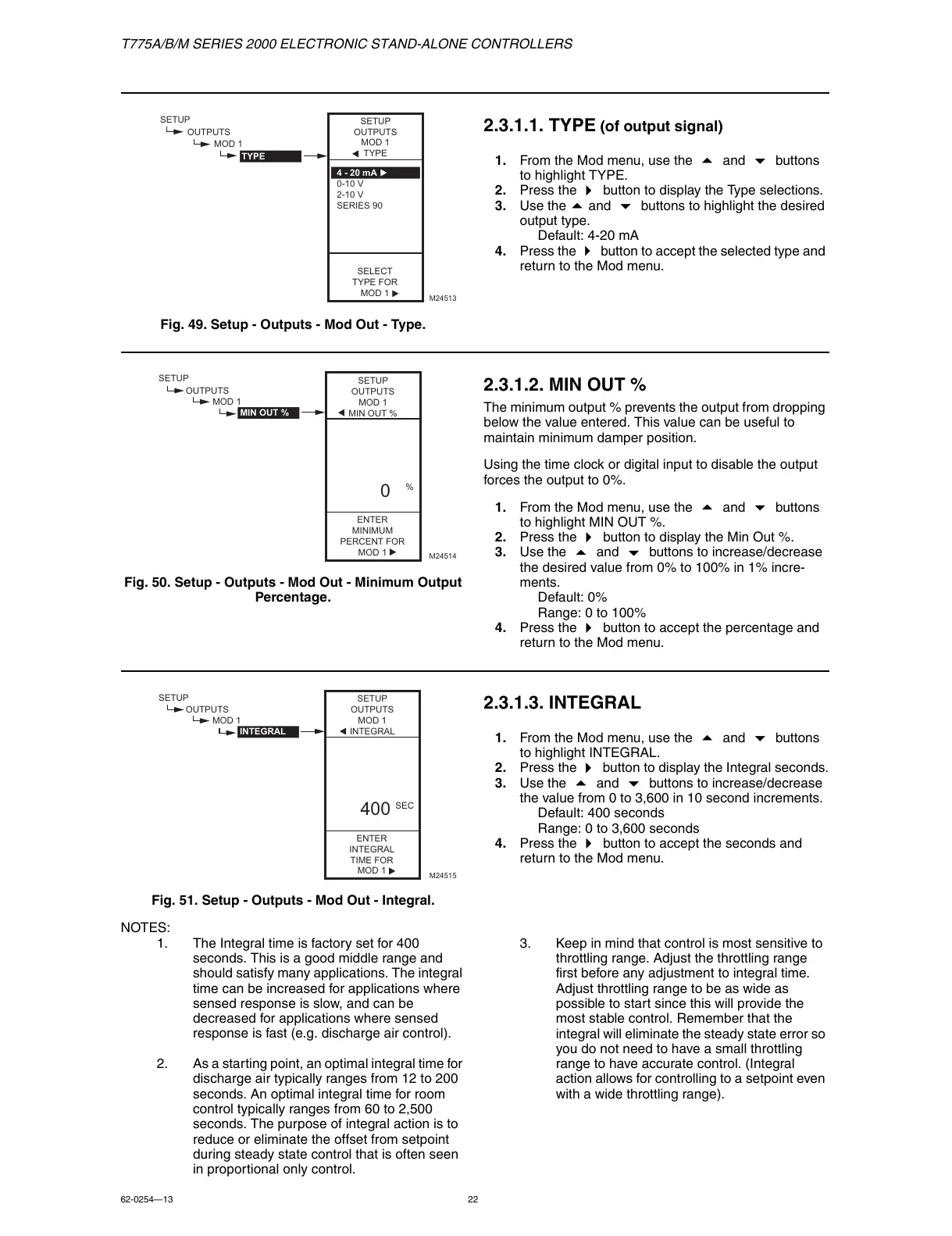

Fig. 51. Setup - Outputs - Mod Out - Integral.

2.3.1.3. INTEGRAL

1. From the Mod menu, use the and buttons

to highlight INTEGRAL.

2. Press the

button to display the Integral seconds.

3. Use the

and buttons to increase/decrease

the value from 0 to 3,600 in 10 second increments.

Default: 400 seconds

Range: 0 to 3,600 seconds

4. Press the

button to accept the seconds and

return to the Mod menu.

NOTES:

1. The Integral time is factory set for 400

seconds. This is a good middle range and

should satisfy many applications. The integral

time can be increased for applications where

sensed response is slow, and can be

decreased for applications where sensed

response is fast (e.g. discharge air control).

2. As a starting point, an optimal integral time for

discharge air typically ranges from 12 to 200

seconds. An optimal integral time for room

control typically ranges from 60 to 2,500

seconds. The purpose of integral action is to

reduce or eliminate the offset from setpoint

during steady state control that is often seen

in proportional only control.

3. Keep in mind that control is most sensitive to

throttling range. Adjust the throttling range

first before any adjustment to integral time.

Adjust throttling range to be as wide as

possible to start since this will provide the

most stable control. Remember that the

integral will eliminate the steady state error so

you do not need to have a small throttling

range to have accurate control. (Integral

action allows for controlling to a setpoint even

with a wide throttling range).

SETUP

OUTPUTS

MOD 1

TYPE

SETUP

OUTPUTS

MOD 1

TYPE

SELECT

TYPE FOR

MOD 1

4 - 20 mA

0-10 V

2-10 V

SERIES 90

M24513

Loading...

Loading...