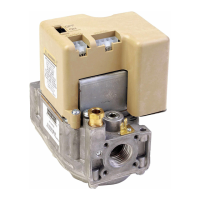

SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

69-1270—3 2

demands on the controls. Special steps are

recommended to prevent nuisance shutdowns and control

failures due to frequent cycling, or severe environmental

conditions such as exposure to moisture, corrosive

chemicals, dust, or excessive heat. Following are the

possible causes of shutdown and the preventative

solutions.

Frequent Cycling

These controls are designed to cycle three to four times

each hour during the heating season. Year around

applications and applications with more frequent cycling

rates can wear out controls more quickly than normal

operation. Perform monthly system checks to make sure

the system operates properly.

Water or Steam Cleaning

Replace any electronic control that gets wet. If the

appliance is likely to be cleaned with water or steam,

cover the control and wiring to protect them from water or

steam flow. Mount the control high enough above the

cabinet bottom to avoid getting it wet during cleaning

procedures.

High Humidity or Dripping Water

Dripping water can cause the control to fail. Never install

an appliance where water can drip on the control. High

humidity around the control can cause the control to

corrode and fail. If the appliance is located in a humid

atmosphere, make sure the air circulation around the

control is adequate to prevent water condensing on the

control. Check the system regularly for signs of

condensation and corrosion.

Corrosive Chemicals

Corrosive chemicals can erode the control, eventually

causing a failure. If chemicals are used for routine

cleaning, make sure they do not touch the control. Where

chemicals are suspended in air, for example, in some

industrial or agricultural applications, protect the control

with an enclosure.

Dust or Grease Accumulation

Heavy accumulations of dust or grease can cause the

control to malfunction. Where dust or grease are

problems, cover the control to limit contamination.

Heat

Excessively high (above 175°F [79°C]) temperatures can

damage the control. Make sure the ambient temperature

at the control does not exceed the control rating. If the

appliance operates at very high temperatures, use

insulation, shielding and proper air circulation as

necessary to protect the control. The appliance

manufacturer should provide proper insulation or

shielding. Make sure there is proper air circulation when

installing the appliance.

Installation

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Follow these warnings exactly as written.

1. Disconnect the power supply before wiring to

prevent electrical shock and equipment

damage.

2. Turn of the gas supply at the appliance service

valve before starting installation to avoid

dangerous accumulation of fuel gas.

3. Perform gas leak test after completing

installation.

4. Do not bend pilot tubing at ignition system

control or pilot burner after tightening the

compression fitting. Bending can cause gas

leakage at the connection.

5. Always install a sediment trap in the gas supply

line to prevent contamination of the ignition

system.

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Follow this warning exactly as written.

• Always change the main and pilot burner

orifices when converting between LP and

natural gas. Follow appliance manufacturer

specifications and instructions.

CAUTION

Equipment Damage Hazard.

Improper device replacement will damage the

equipment.

The SV9501, SV9502, SV9602, and SV9601

provide direct replacement only as shown in Table

4 or Table 5 of this manual. Use the Y8610 to

convert standing pilot systems to electronic

ignition systems.

CAUTION

Equipment Damage Hazard.

Can Burn Out Heat Anticipator in Thermostat.

1. Never apply a jumper across or short the

terminals in the SV9501, SV9502, SV9602, or

SV9601 connectors or appliance wiring

harnesses.

2. Never short the electric fan timer (EFT) output.

Shorting the output can damage the EFT drive

circuitry.

IMPORTANT

These ignition system controls are shipped with

protective seals over inlet and outlet tappings.

Do not remove seals until ready to connect

piping.

Follow the appliance manufacturer’s instructions if

available. Otherwise, use these instructions as a guide.

Loading...

Loading...