7 60-2102—7

Fig. 8—Recommended arrangement for

normally closed operation.

V51E

INSTALLATION

5. Use the four large cap screws supplied with the link-

age assembly to secure the motor to the adapter plate.

6. Add the ball joint assembly and push rod as shown in

Fig. 10.

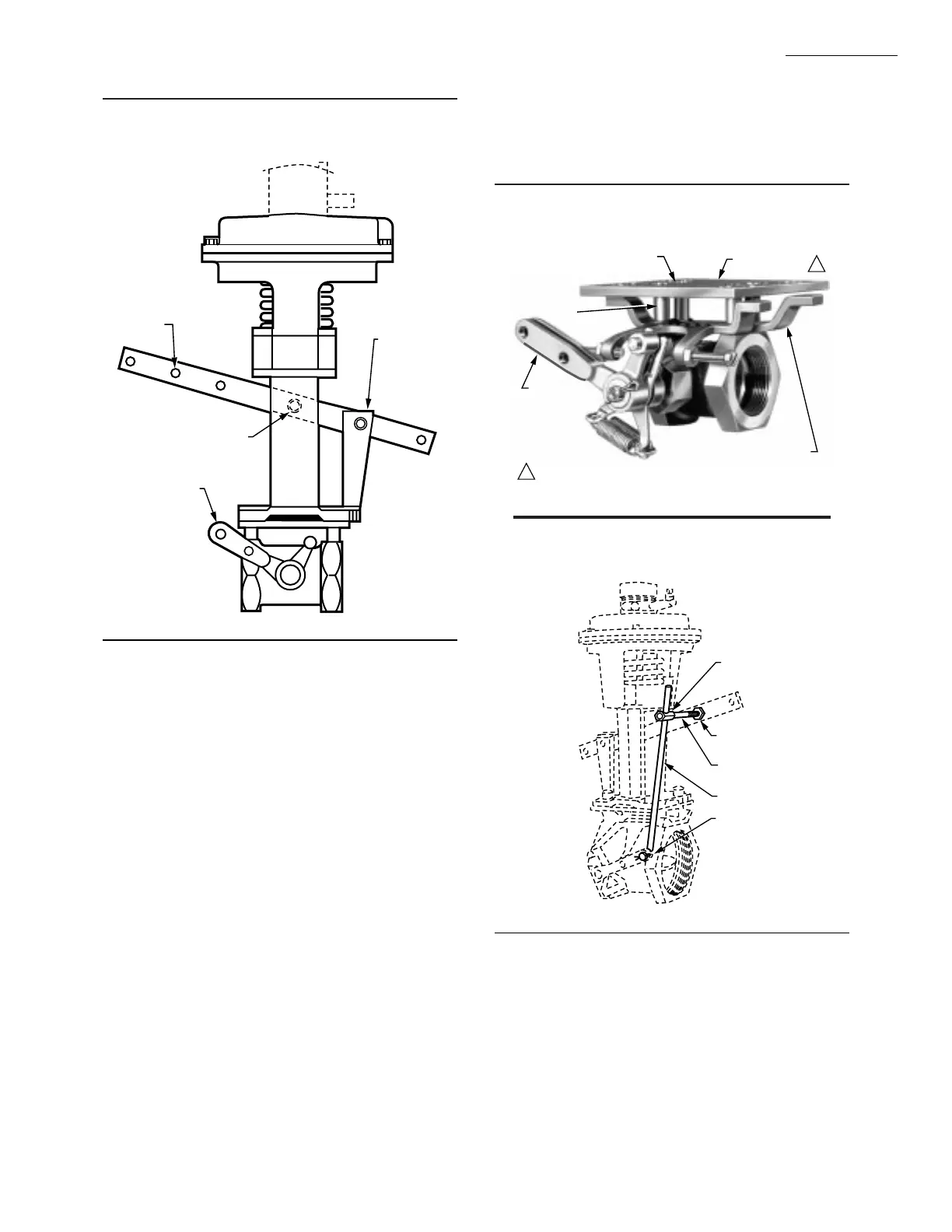

Fig. 9—Relationship of parts in V51E.

M9528

LOAD

TAKEOFF

CLEVIS

VALVE ACTUATING ARM

(VALVE CLOSED)

PIVOT

(THREADED

HOLE IN

LEVER)

1. Remove the four round-head machine screws and

washers holding the stop bracket to the valve hex at each end.

Do not remove the stop bracket

2. Position the adapter plate over the stop bracket so that

the adapter plate holes match the stop bracket holes.

3. Insert the flat head screws supplied with the linkage

assembly through plate, spacers, and stop bracket and into

each hex. Tighten securely. The spacers prevent contact of

adapter plate and stop bracket. See Fig. 9.

4. Mount the lever arm (13-3/4 in. [349.3 mm]) supplied

with the motor so the load takeoff holes will be at the same

end of the valve as the valve actuating arm.

NOTE: Both motor lever and valve arm could be installed

180 degrees from the positions shown in Figs. 7 and 8, if

more convenient. Use bushing hole at the clevis.

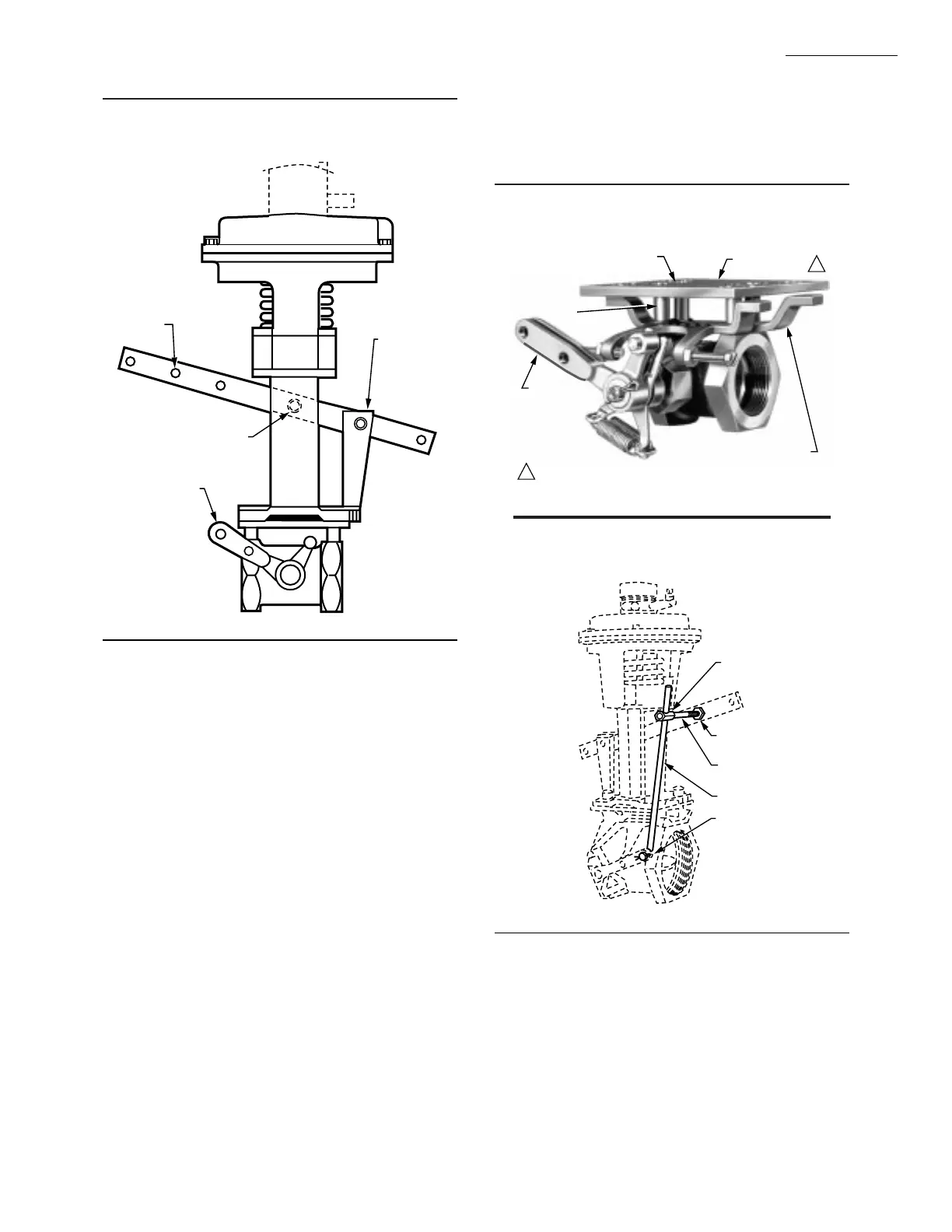

Fig. 10—Typical combination of V51E, Air-O-

Motor Pneumatic Actuator, and Q524 Linkage.

UPPER

BALL JOINT

1 NUT EACH

SIDE OF LEVER

BALL JOINT

ASSEMBLY

PUSH ROD

LOWER

BALL JOINT

M9583

FLAT HEAD SCREWS (4)

ADAPTER PLATE

SPACERS (4)

STOP

BRACKET

VALVE

ACTUATING

ARM

SUPPLIED WITH LINKAGE.1

M9536

1

Loading...

Loading...