reduce the draw weight so you may quickly re-adjust to the prior weight the

next time you shoot.

6. Lubricate the axles of the eccentric wheels from time to time (WD 40 is

excellent).

Do not oil the coble grooves of the wheels.

7. To assure best results, we recommend the use of Hoyt/Easton replacement

ports,

strings, cables, etc.

DRAW LENGTH ADJUSTMENTS

First, check to see that your bow is set at your desired draw length. The Hoyt/

Easton bows equipped with Irl-drow wheels" ore set In the center slot from

the factory and con be adjusted for a one Inch longer or one inch shorter

draw length. If you hove purchased a bow without the trl-drow system, you

con,

to a limited degree, shorten the draw length by using a shorter

bowstring.

If you cannot obtain your proper draw length, return the bow to

your archery pro shop for a different size wheel.

NOTE:

Although the use of a longer string would hove the opposite effect of

lengthening the draw, factory setting allows little adjustment In this direction.

Lengthening the draw in this manner can cause cable overlap, and hence,

create unnecessary campllcatlons.

A slight weight change will accompany any change in draw length and

may be compensated by tightening or loosening the limb weight adjust-

ment bolts. Occasionally, however, the full amount of peak weight may be

lost when reducing draw length.

With "energy wheels," the draw length con be changed

by the following methods.

1.

Using an Alien wrench, begin by loosening each limb weight adjustment

bolt two turns (counterclockwise), alternating be-

tween the top and bottom limb (remember to keep

track at the exact number of turns In order to return

your poundage to the original weight). Continue

loosening each bolt until there is enough coble

slack to move the cables to the desired slots. After

placing cables In desired shorter draw length (-) or

longer draw length

(-t-),

alternately re-tlghten limb

weight adjustment bolts (two turns at a time) while ensuring cables remain in

proper slots. Do not draw bow when limbs ore in relaxed state.

2.

Using a string changer or long bowstring, leave the bow set at the original

weight. Place the string changer or long string (6" to 8" longer than regular

string) on each unused teardrop of the cables. Pull string changer to remove

regular bowstring and relax changer to get slock in the cables. When using

the long string, lower the long bowstring to the floor and stand on It. Next, pull

the bow up until the limbs flex enough to remove the regular bowstring; now

let the bow relax. The cables should be slock enough to move to the desired

slots.

To reset, simply reverse the procedure, making sure the cables remain

in place.

SEHING BOW WEIGHT

Adjusting the weight of your compound bow is very easy Using the Allen

wrench supplied with your bow simply turn the limb weight adjustment bolts

clockwise to Increase poundage or counterclockwise to reduce poundage.

One full 360° turn of the limb weight adjustment bolt will effectively Increase

or decrease heavy weight bows approximately four pounds per turn and

lightweight bows approximately two pounds per

turn.

After setting bow

weight, be sure to check tiller.

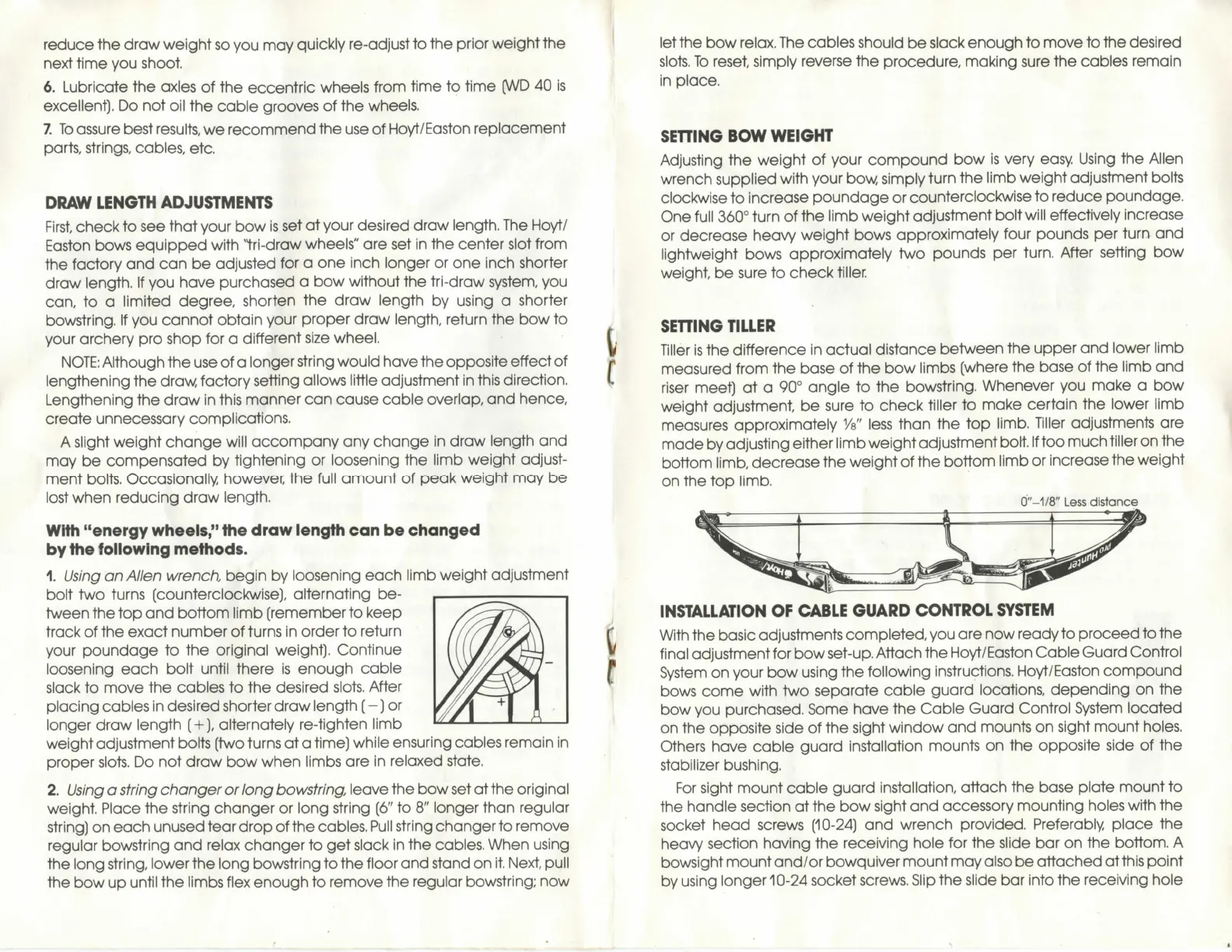

SEniNG TILLER

Tiller Is the difference In actual distance between the upper and lower limb

measured from the base of the bow limbs (where the base of the limb and

riser meet) at a 90° angle to the bowstring. Whenever you moke a bow

weight adjustment, be sure to check tiller to moke certain the lower limb

measures approximately VB" less than the top limb. Tiller adjustments are

made by adjusting either limb weight adjustment bolt.

If

too much tiller on the

bottom limb, decrease the weight of the bottom limb or Increase the weight

on the top limb.

0"-1/8" Less distance

INSTALLATION OF CABLE GUARD CONTROL SYSTEM

With the basic adjustments completed, you ore now ready to proceed to the

final adjustment for bow set-up. Attach the Hoyt/Easton Coble Guard Control

System on your bow using the following Instructions. Hoyt/Easton compound

bows come with two separate cable guard locations, depending on the

bow you purchased. Some hove the Coble Guard Control System located

on the opposite side of the sight window and mounts on sight mount holes.

Others hove coble guard Installation mounts on the opposite side of the

stabilizer bushing. ,sy-:

For sight mount coble guard installation, attach the base plate mount to

the handle section at the bow sight and accessory mounting holes with the

socket head screws (10-24) and wrench provided. Preferably, place the

heavy section having the receiving hale for the slide bar on the bottom. A

bowslght mount and/or bowqulver mount may also be attached at this point

by using longer 10-24 socket screws. Slip the slide bar into the receiving hole

Loading...

Loading...