ENWW Image formation system 173

2 The DC controller detects the density of the density detection patterns on the ITB by the image

density detection and sends the data back to the formatter.(See Image density detection,

below)

3 The formatter calibrates the halftone based on such data to obtain an ideal halftone image.

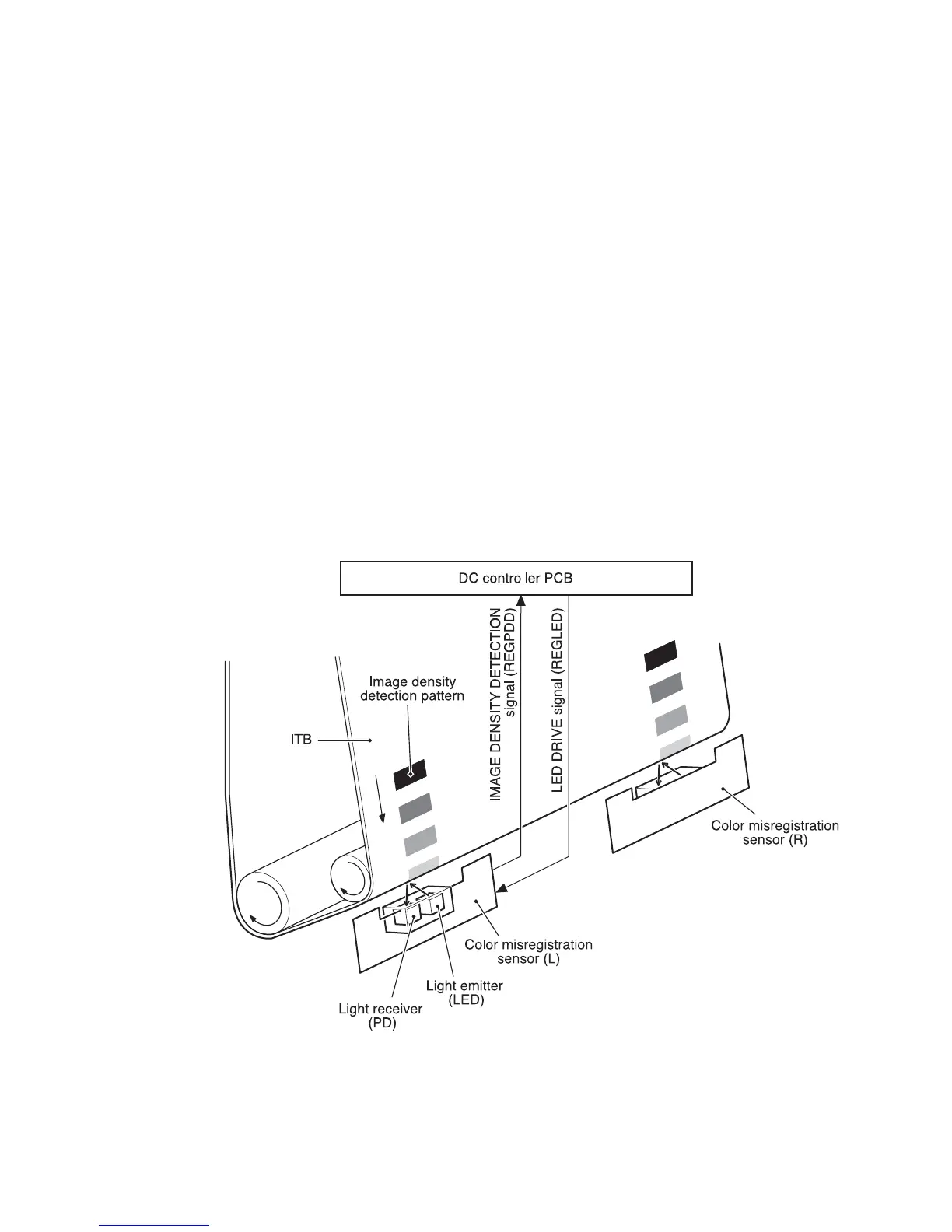

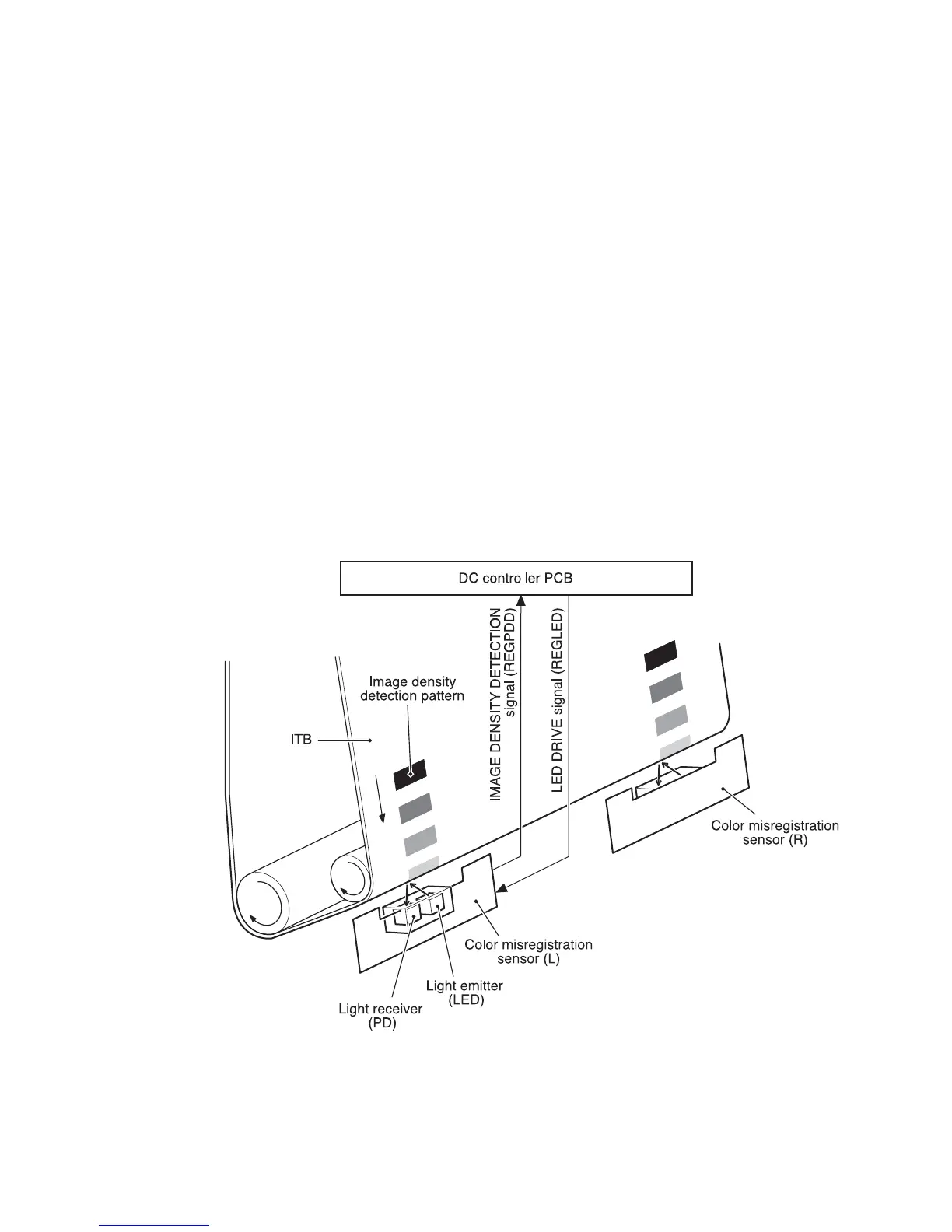

Image density detection

The density of all four colors’ image density detection patterns formed on the ITB is detected to

adjust the image density.

The DC controller controls the color misregistration sensor (PS5) during the foregoing D-max and

D-half controls for this detection. PS5 consists of two detection sensors, which are used in

conjunction with the images on the ITB, each having one light emitter (LED) and one light receiver

(PD).

The following is the sequence of this control.

1 The DC controller sends LED DRIVE signal (REGLED) and lets the LED emit light.

2 The light of the LED is reflected off the density detection patterns on the ITB and received by

the PD on the sensor. The light amount received at the PD differs depending on the toner

density where the light is reflected off.

3 The light receiver converts the received light amount to voltage and sends it to the DC

controller in the form of the IMAGE DENSITY DETECTION signal (REGPDD).

4 The DC controller converts the REGPDD signals to density value (digital) and stores them.

Figure 5-55 Image density detection

Loading...

Loading...