Model 6960A

SERVICING

ETCHED

CIRCUIT

IOARDS

Section

V

Excessive

heat

or

pressure

can

lift

the

copper

strip

from

the

board.

Avoid

damage

by

using

a low

power

soldering

iron

(50

watts

maximum)

and following

these

instructions.

Copper

that

lifts

off

the

board

should

be

cemented

in

place

with a quick

drying

acetate

base

cement

having good

electrical

insulating

properties.

A

break

in

the

copper

should

be

repaired

by

soldering

a

short

length

of

tinned

copper

wire

across

the

break.

Use

only high

quality

rosin

core

solder

when

repairing

etched

circuit

boards.

NEVER USE PASTE FLUX.

After

soldering.

clean

off

any

excess

flux and

coat

the

repaired

area

with a high

quality

electrical

varnish

or

lacquer.

When

replacing components with multiple mounting pins such

as

tube

sockets,

electrolytic

capacitors,

and

potentiometers, it

will

be

necessary

to

lift each

pin

slightly. working around the components

several

times

until

it

is

free.

WARNING:

If

the

specific

instructions

outlined in

the

steps

below

regarding

etched

circuit

boards

without

eyelets

are

not followed.

extensive

damage

[Q

the etched circuit board will

result,

CONDUCTOR

SIDE

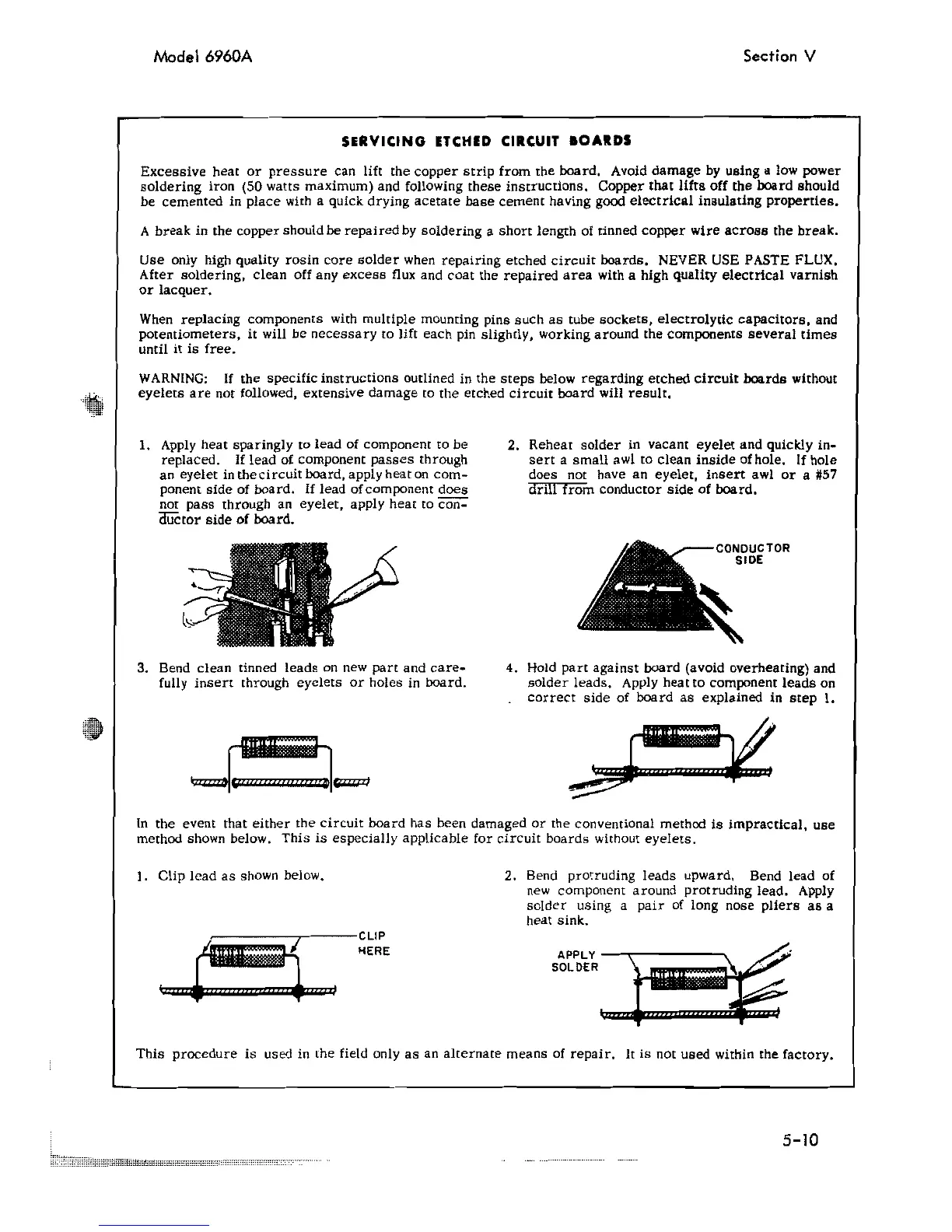

1. Apply

heat

sparingly

to

lead

of component

to

be

replaced.

If

lead

of component

passes

through

an

eyelet

in

the

circuit

board. apply heat

on

com

...

ponent

side

of

board.

If

lead

of

component

does

not

pass

through

an

eyelet,

apply

heat

to

Coil-

auctor

side

of

board.

3. Bend

clean

tinned

leads

on new part and

care-

fully

insert

through

eyelets

or

holes

in board.

2.

Reheat

solder

in

vacant

eyelet

and

quickly

in-

sert

a

small

awl

to

clean

inside

of

hole. If hole

does

not

have

an

eyelet,

insert

awl

or

a #57

drill

from

conductor

side

of

board.

4. Hold

part

against

board

(avoid

overheating)

and

solder

leads.

Apply

heat

to

component

leads

on

correct

side

of

board

as

explained

in

step

I.

In

the event that

either

the

circuit

board has been damaged or the conventional method

is

impractical,

use

method shown below. This

is

especially

applicable for

circuit

boards without

eyelets.

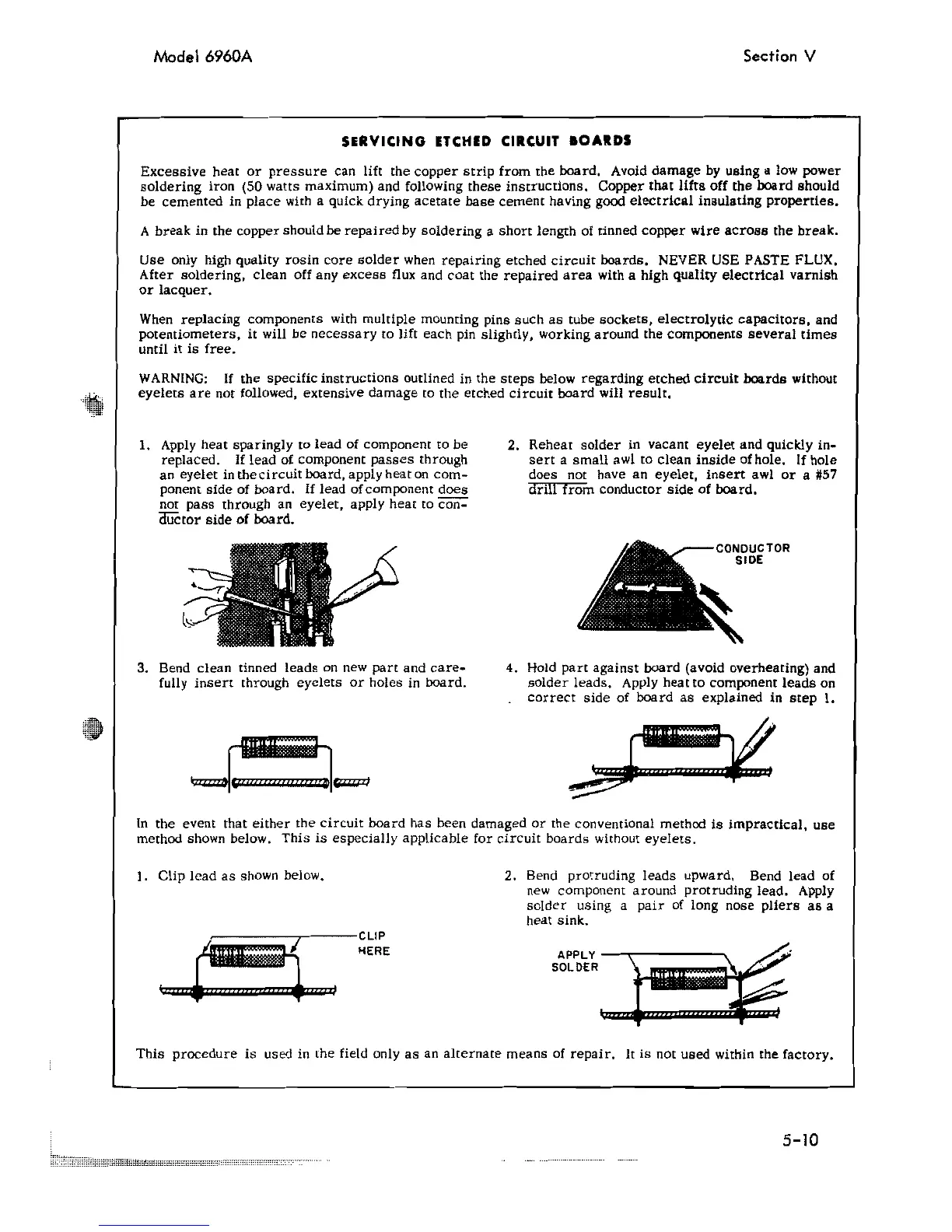

).

Clip

lead

as

shown below.

~,-----r---CLIP

~HERE

2. Bend

protruding

leads

upward. Bend

lead

of

new

component around protruding lead. Apply

solder

using a pair of long nose

pliers

as

a

heat sink.

...

,,~

SOLDER

#W9ill9Willill

~

This

procedure

is

used in the field only

as

an

alternate means

of

repair.

It

is

not used within the factory.

5-10

Loading...

Loading...