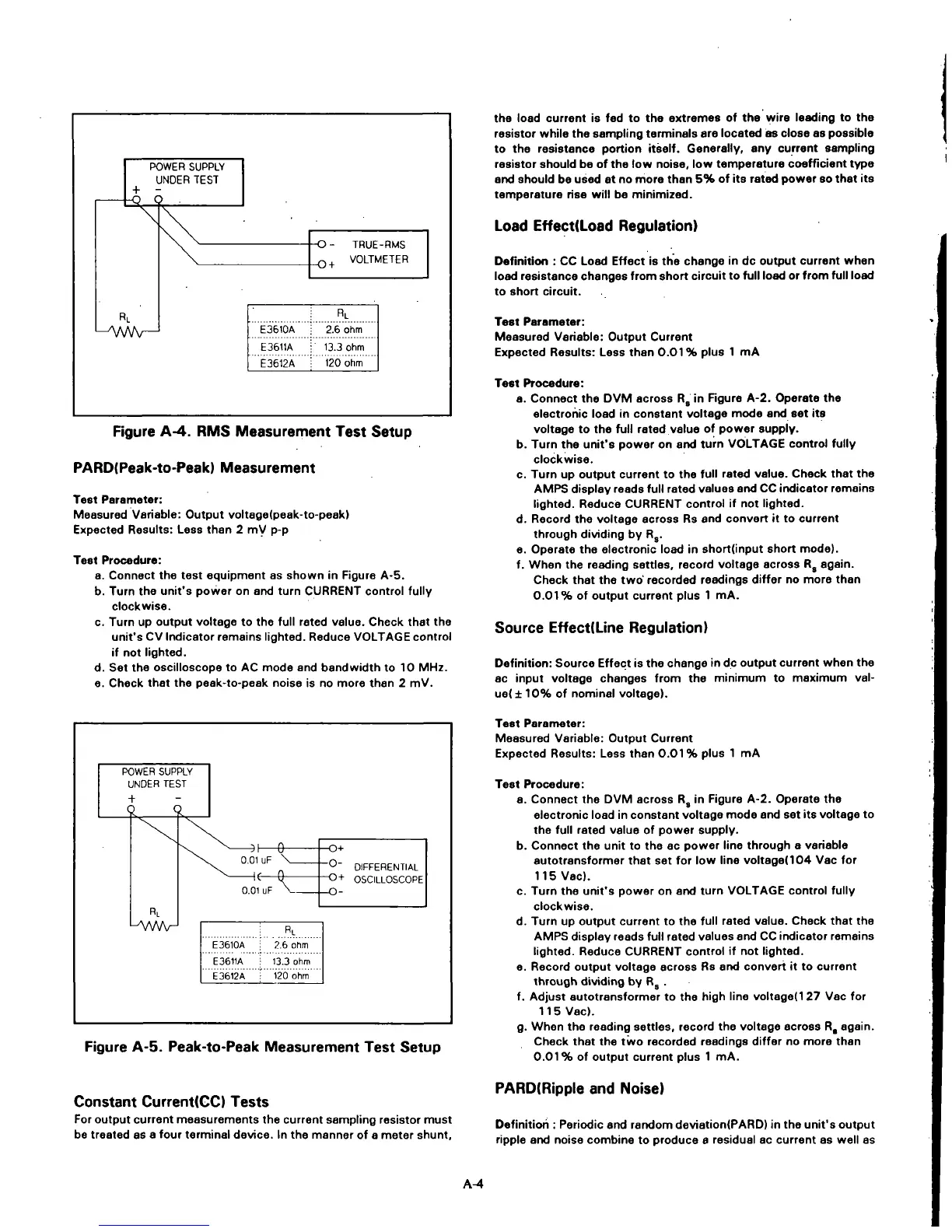

POWER SUPPLY

UNDER TEST

-1-

-

^

RL

L^VWV—

1

\

E3610A

E3611A

E3612A

-O - TRUE

_(-,,

VOLB

RL

2.6 ohm

13.3 ohm

120 ohm

-RMS

/lETER

Figure A-4. RMS Measurement Test Setup

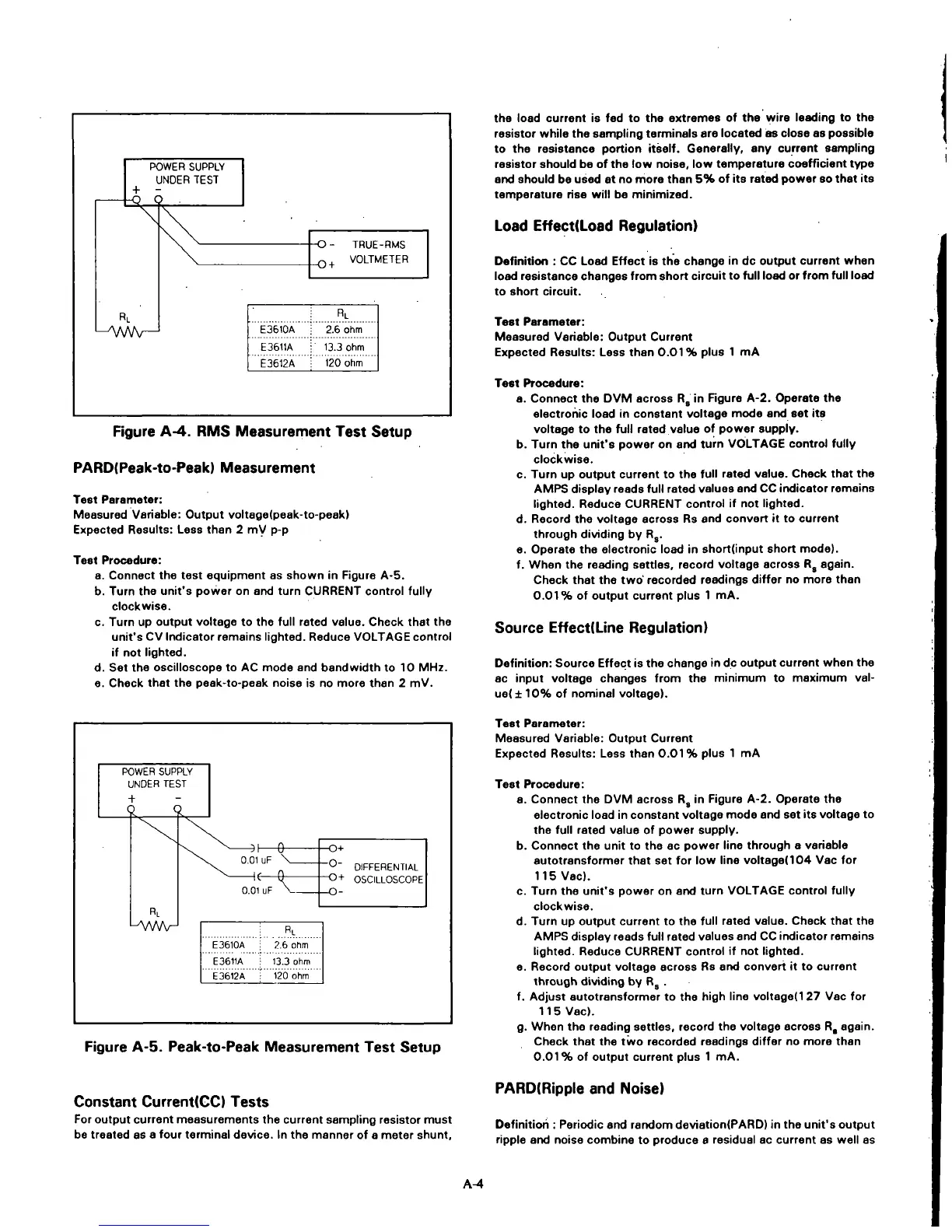

PARD(Peak-to-Peak) Measurement

Test Parameter:

Measured Variable: Output voltage(peak-to-peak)

Expected Results: Less than 2 mV p-p

Test Procedure:

a. Connect the test equipment as shown in Figure A-5.

b. Turn the unit's power on and turn CURRENT control fully

clockwise.

c. Turn up output voltage to the full rated value. Check that the

unit's CV Indicator remains lighted. Reduce VOLTAGE control

if not lighted.

d.

Set the oscilloscope to AC mode and bandwidth to 10 MHz.

e. Check that the peek-to-peak noise is no more than 2 mV.

the load current is fed to the extremes of the wire leading to the

resistor while the sampling terminals are located as close as possible

to the resistance portion itself. Generally, any current sampling

resistor should be of the low noise, low temperature coefficient type

arxl should be used at no more than 5% of its rated power so that its

temperature rise will be minimized.

Load Effect(Load Regulation)

Definition : CC Load Effect is the change in dc output current when

load resistance changes from short circuit to full load or from full load

to short circuit.

Test Parameter:

Measured Variable: Output Current

Expected Results: Less than 0.01% plus 1 mA

Test Procedure:

a. Connect the DVM across R, in Rgure A-2. Operate the

electronic load in constant voltage mode and set its

voltage to the full rated value of power supply.

b. Turn the unit's power on and turn VOLTAGE control fully

clockwise.

c. Turn up output current to the full rated value. Check that the

AMPS display reads full rated values and CC indicator remains

lighted.

Reduce CURRENT control if not lighted.

d.

Record the voltage across Rs and convert it to current

through dividing by R,.

e. Operate the electronic load in short(input short mode).

f. When the reading settles, record voltage across R, again.

Check that the two' recorded readings differ no more than

0.01%

of output current plus 1 mA.

Source Effect(Line Regulation)

Definition:

Source Effect is the change in dc output current when the

ac input voltage changes from the minimum to maximum val-

ue( ± 10% of nominal voltage).

POWER SUPPLY

UNDER TEST

RL

LAAAAr-l

-^1—Q-

0.01 uF

0.01

uF V_

-O-i-

"O-

DIFFERENTIAL

-0+ OSCILLOSCOPE

-O-

RL

E3610A

E3611A

E 3612 A

2.6 ohm

• 13.3 ohm

• 120 ohm

Figure A-5. Peak-to-Peak Measurement Test Setup

Test Parameter:

Measured Variable: Output Current

Expected Results: Less than 0.01% plus 1 mA

Test Procedure:

a. Connect the DVM across R, in Figure A-2. Operate the

electronic load in constant voltage mode and set its voltage to

the full rated value of power supply.

b. Connect the unit to the ac power line through a variable

autotransformer that set for low line voltage(104 Vac for

115 Vac).

c. Turn the unit's power on and turn VOLTAGE control fully

clockwise.

d.

Turn up output current to the full rated value. Check that the

AMPS display reads full rated values and CC IrKlicator remains

lighted.

Reduce CURRENT control if not lighted.

e. Record output voltage across Rs and convert it to current

through dividing by R, .

f. Adjust autotransformer to the high line voItage(127 Vac for

115 Vac).

g.

When the reading settles, record the voltage across R, again.

Check that the two recorded readings differ no more than

0.01%

of output current plus 1 mA.

Constant Current(CC) Tests

For output current measurements the current sampling resistor must

be treated as a four terminal device. In the manner of a meter shunt.

PARD(Ripple and Noise)

Definitioii:

Periodic and rarxJom deviation(PARD) in the unit's output

ripple and noise combine to produce a residual ac current as well as

A-4

Loading...

Loading...