LP-387 Rev. 7.3.15

11

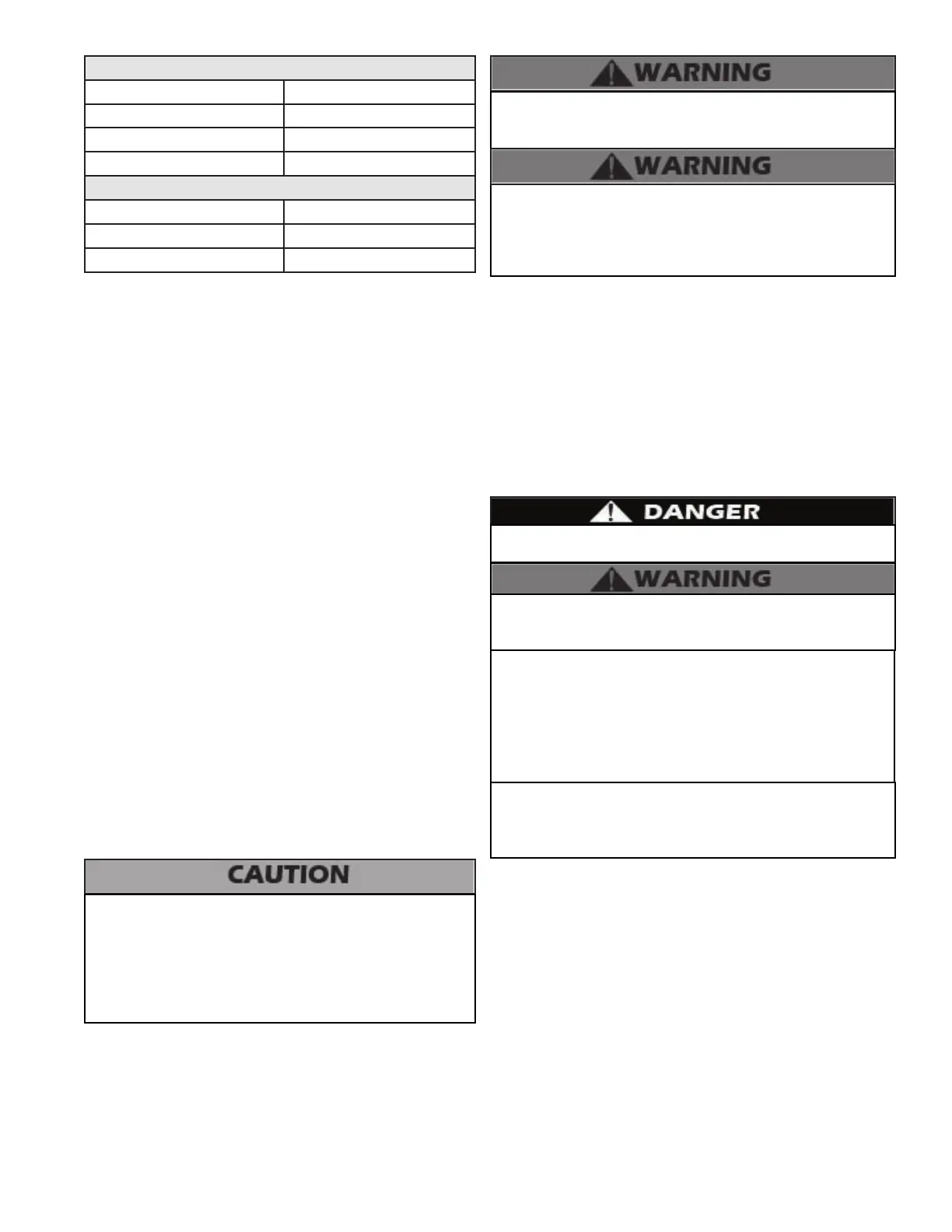

Required Amount of Bolts for Wall-Mounting the Boiler

Model Amount of Bolts

EFT-55 - 110 2

EFT-155 - 285 4

EFT-399 6

Pilot Hole Size by Wood Type

Type Drill Bit Size

Soft 3/32”

Hard 3/16”

Table 1 - Bolts Required and Pilot Hole Size for Wall-Mounting

the EFT Boiler

G. Residential Garage, Closet, and Alcove Installations

Precautions

If the boiler is located in a residential garage, per ANSI Z223.1:

• Install the boiler burner and ignition devices a mini-

mum of 18” above the oor of the garage. This will

ensure the burner and ignition devices are well o the

oor.

• Locate or protect the boiler so it cannot be damaged

by a moving vehicle.

Check with your local Authority Having Jurisdiction for

requirements when installing boiler in a garage, closet, or

alcove. Please read the entire manual before attempting

installation. Failure to properly take factors such as boiler

venting, piping, condensate removal, and wiring into account

before installation could result in wasted time, money, and

possible property damage and personal injury.

For closet or alcove installations, a two pipe venting system

must be used. Failure to follow this warning could result in

substantial property damage, severe personal injury, or death.

2. Mounting to a Metal Frame

a. The provided mounting bracket must be mounted to the

center of at least 2 studs using standard steel or stainless

steel toggle bolts 3/16” diameter or larger, and at least 2”

long for direct mounting on stud for EFT-55 – 110 models,

and 3/8” diameter or larger, and at least 2” long for EFT-155

– 399 models for direct mounting on at least 18 gauge studs.

Be sure the bracket is level and mark the hole location of the

top bracket height and horizontal stud location. Ensure the

marked holes are located in the center of the building frame

(studs).

b. 2” is the minimum toggle bolt length if the bracket is directly

on stud. Increase length for any materials covering the studs.

c. Predrill holes on the marked stud locations. The predrilled

holes should be ½” in diameter for 3/16” bolts, and ¾” in

diameter for 3/8” bolts, to allow for the collapsed wings of the

toggle to slide through. Ensure that the predrilled holes are

straight and square to the wall. Failure to do so could lead to

insucient support of out of level boiler. See Figure 4.

d. Using the predrilled holes, mount the hanger bracket to the

building frame (studs) with the toggle bolts. Ensure that the

bolt toggles are through the stud and expanded catching the

inside of the stud. Tighten the toggle bolt until the mounting

bracket is secure. Hang boiler on the now wall mounted

bracket. Be certain that the bracket is engaged before letting

the boiler hang free. Slowly release the weight of the boiler

while ensuring the bracket is properly secure. Verify that the

boiler is securely mounted before leaving it unsupervised.

H. Exhaust Vent and Intake Pipe

The boiler is rated ANSI Z21.13 Category IV (pressurized vent,

likely to form condensate in the vent) and requires a special vent

system designed for pressurized venting.

NOTE: The venting options described here (and further

detailed in the Venting section, this manual) are the lone

venting options approved for this boiler. Failure to vent the

boiler in accordance with the provided venting instructions

will void the warranty.

NOTE: For installations using room air for combustion, refer to

the boiler venting section, this manual.

The space must be provided with correctly sized combustion/

ventilation air openings for all other boilers located in the space

with the boiler. Do not install the boiler in an attic. Failure to

comply with these warnings could result in substantial property

damage, severe personal injury, or death.

Failure to vent the boiler properly will result in serious personal

injury or death.

Do not attempt to vent this boiler by any means other than

those described in this manual. Doing so will void the warranty

and may result in severe personal injury or death.

Vents must be properly supported. Boiler exhaust and intake

connections are not designed to carry heavy weight. Vent

support brackets must be within 1’ of the boiler and the balance

at 4’ intervals. Boiler must be readily accessible for visual

inspection for rst 3’ from the boiler. Failure to properly support

vents could result in property damage, severe personal injury,

or death.

The exhaust discharged by this boiler may be very hot. Avoid

touching or other direct contact with the exhaust gases of the

vent termination assembly. Doing so could result in severe

personal injury or death.

1. Direct Vent of Exhaust and Intake

If installing a direct vent option, combustion air must be drawn

from the outdoors directly into the boiler intake and exhaust

must terminate outdoors. There are three basic direct vent

options detailed in this manual: 1. Side Wall Venting, 2. Roof

Venting, and 3. Unbalanced Venting.

Be sure to locate the boiler such that the exhaust vent and

intake piping can be routed through the building and properly

terminated. Dierent vent terminals can be used to simplify and

eliminate multiple penetrations in the building structure (see

Optional Equipment in Venting Section). The exhaust vent and

intake piping lengths, routing, and termination methods must

all comply with the methods and limits given in the Venting

Section, this manual.

When installing a combustion air intake from outdoors, care

must be taken to utilize uncontaminated combustion air. To

prevent combustion air contamination, see Table 2.

Loading...

Loading...