67

LP-171 Rev. 3.3.15

No flame detected – The

heater will make three

attempts at ignition before

the control goes into this

lockout condition. *See

spark electrode detail.

1. Watch the igniter through the observation window provided.

2. If there is no spark, check the spark electrode for the proper ¼” gap by holding two quarters together and

sliding them through the gap.

3. Remove any corrosion from the spark electrode and flame rectifier probe.

4. If there is a spark but no flame, check the gas supply to the heater.

5. If there is a flame, check the flame sensor.

6. Check any flue blockage or condensate blocks.

Loss of flame signal – The

heater will relight 4 times

before the control goes into

this lockout condition. Will

reset in 1 hour.

1. Monitor the gas pressure to the unit while in operation.

2. Assure that the flame is stable when lit.

3. Check to see if the green light on the display module is out while the heater is running.

4. If the green light doesn’t come on or goes off during operation check the flame signal on the status menu.

5. If the signal reads less than 1 microampere, clean the flame rectifier probe.

6. If the flame rectifier probe continues to read low, replace it.

False flame signal – The

heater will lock out if it

senses a flame signal when

there should be none

present.

1. Turn the gas off to the unit at the service valve.

2. If the flame signal is still present replace the igniter.

3. If the flame signal is not present after turning off the gas supply, check the gas valve electrical connection.

4. If there is no power to the gas valve, remove the valve and check for obstruction in the valve seat or replace

the gas valve.

5. Turn the gas on at the service valve after corrective action is taken.

Combustion fan speed out

of tolerance – The

appliance will lock out if it

senses that the fan speed

is not at 70% the expected

speed for more than 60

seconds.

1. Check the combustion fan wiring.

2. Replace the combustion fan.

3. Replace the control board.

The control has been

programmed by a

technician or the factory.

After programming, the

control is left in a locked out

mode.

Press the RESET key for at least 1 second to begin use of the control.

Call factory for further assistance.

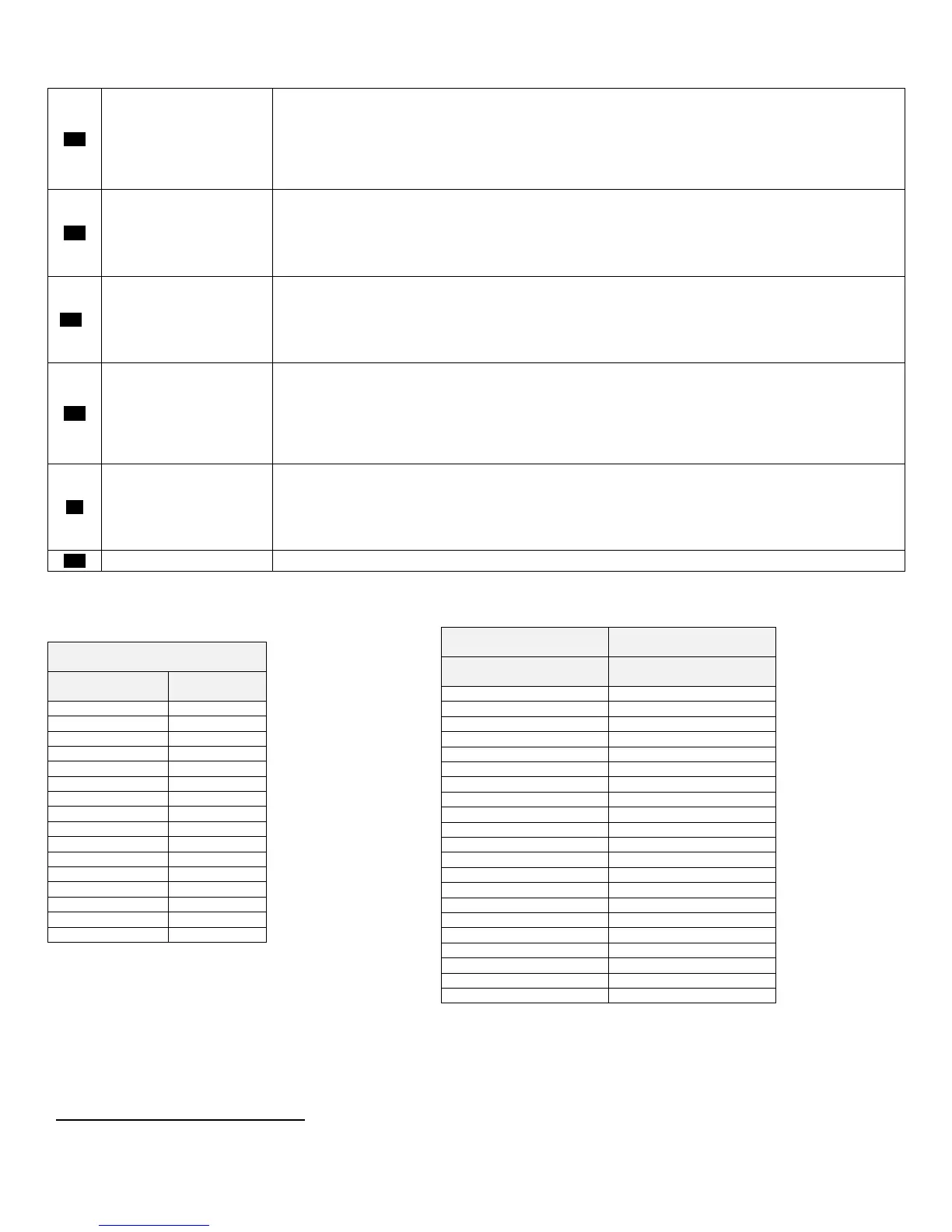

Table 15

Resistance Tables

PART 15 – MAINTENANCE

A. MAINTENANCE PROCEDURES

Periodic maintenance should be performed once a year by a qualified service technician to assure that all the equipment is in safe

efficient operation. The owner can make necessary arrangements with a qualified heating contractor for periodic maintenance of the

HEATER SENSOR

(7250P-059)

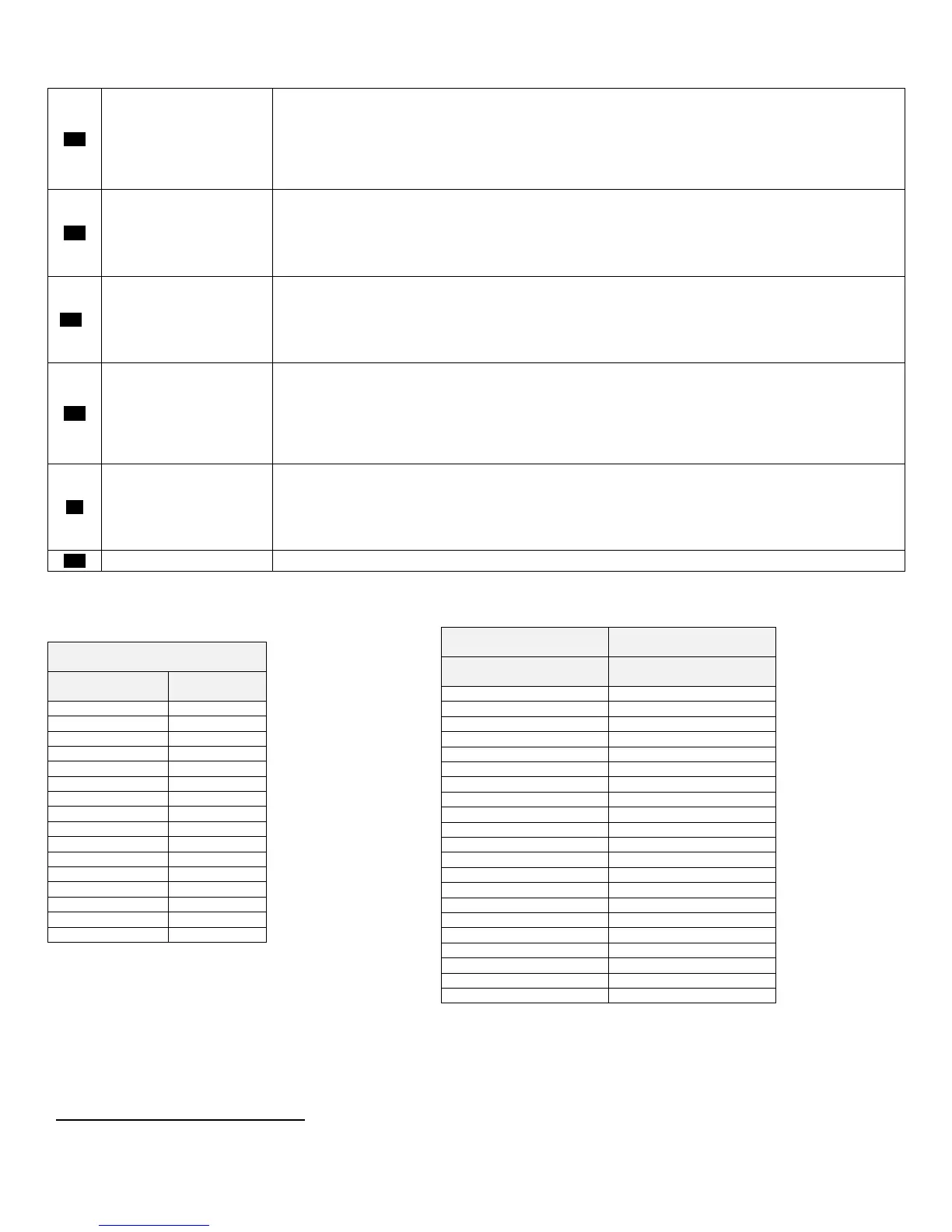

INDIRECT SENSOR

(7250P-325)

HEATER AND INDIRECT

TEMPERATURE (

o

F)

OUTDOOR SENSOR

(7250P-319)

Loading...

Loading...