4

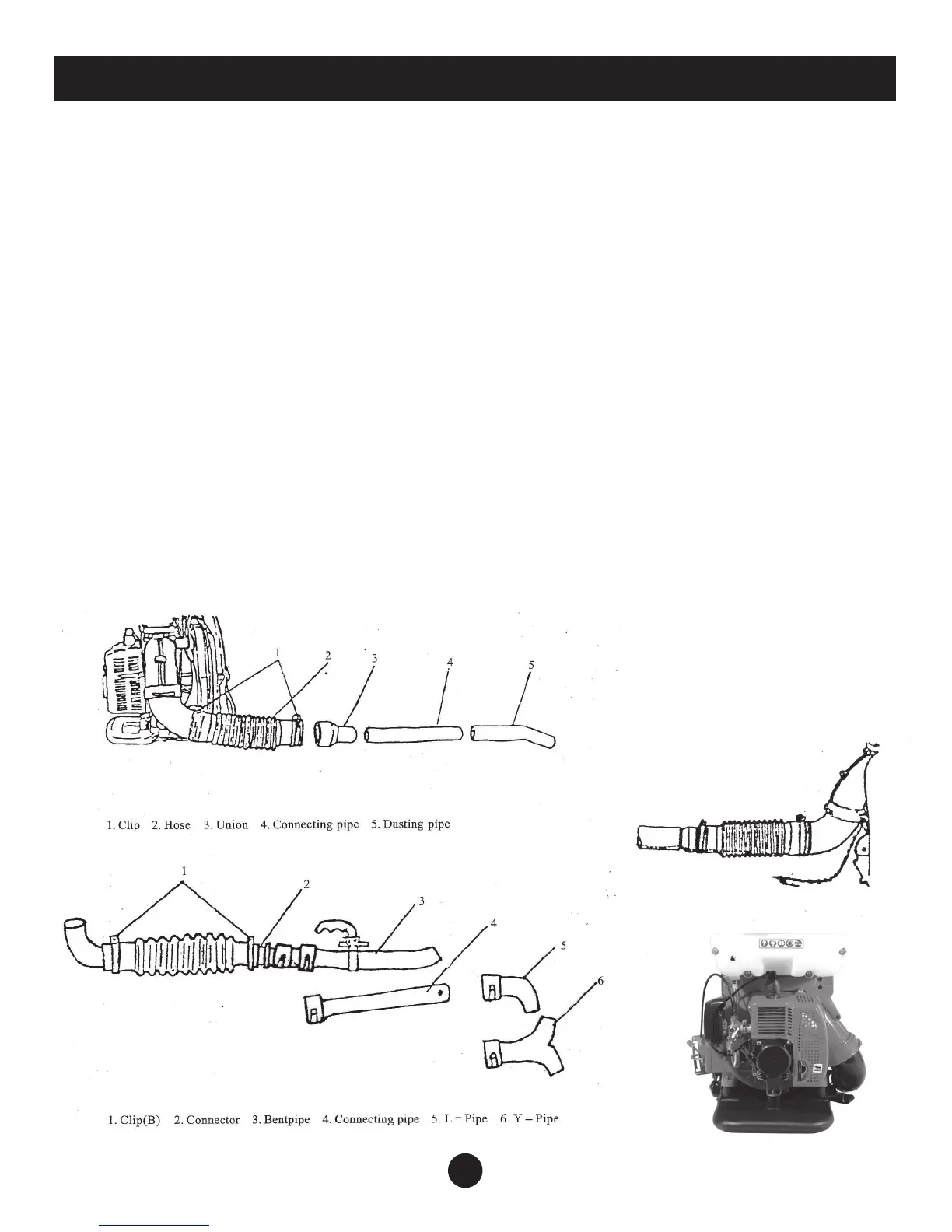

ASSEMBLY FOR DUSTING OPERATION

Changing spray plates.

Unscrew fill cover from tank. Remove the clamp and clear spray hose form the hose

connector on the outside of the tank. Remove the collared end of the small black rubber

hose from the spray plate. Remove the small black rubber hose, hose connector, gasket, and

retainer nut from tank. Remove the clear air hose from the filler cap. Remove the two 14mm

hex nuts that hold the chemical tank to the frame. Lift tank off the frame. Remove the spraying

plate from frame and replace with the dusting plate. The dusting plate has an off center

opening that should be aligned with the opening in the frame.

Tank preparation.

Screw tank plug onto side of tank.

Hose preparation.

Loosen up the main tube thumb clamp. Remove fluid hoses, on/off switch and spray nozzle as

a unit. The remaining accessory tubes can be fitted together as needed.

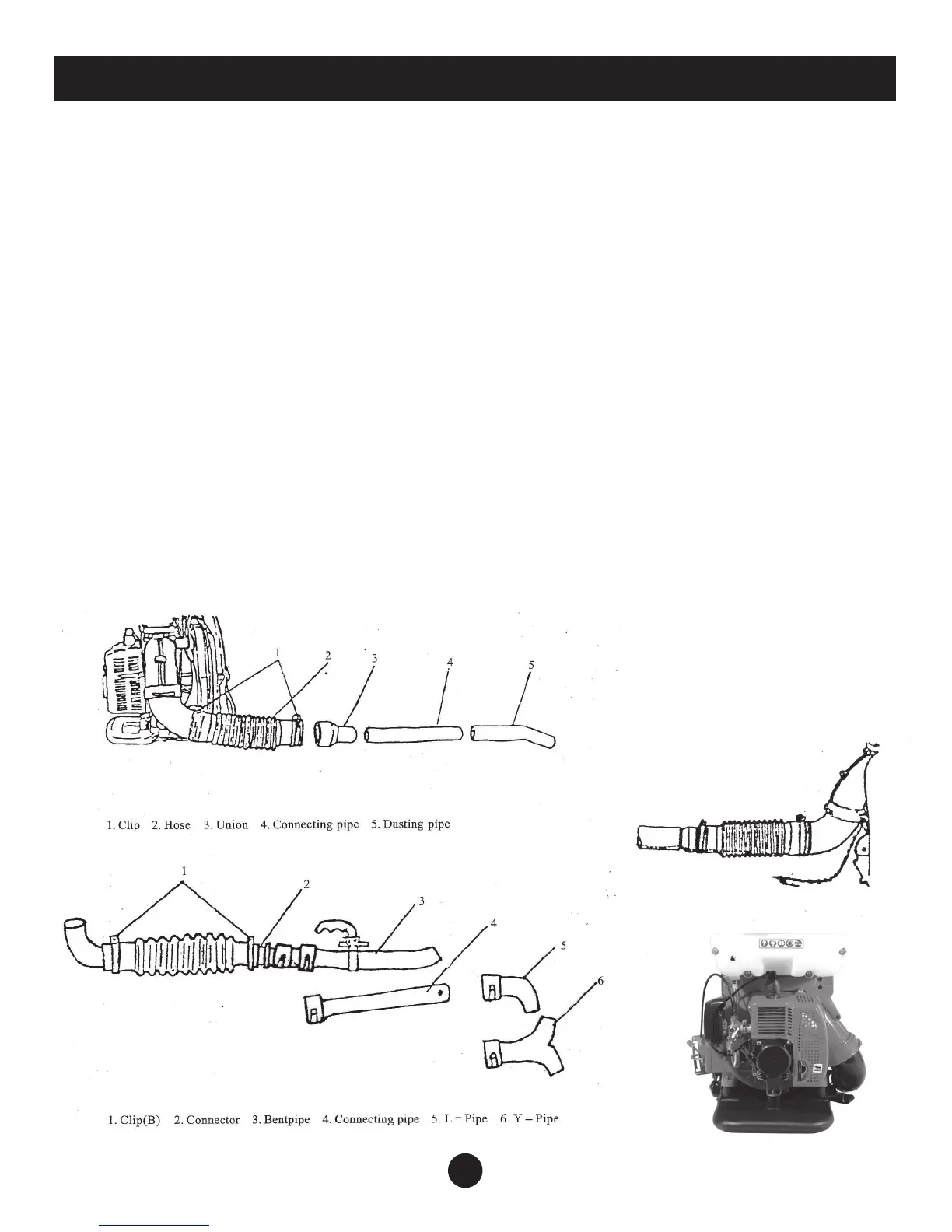

Anti-electrostatic installation.

Dusting or spreading granule chemical may cause a static electricity build-up. Some of

the factors that can cause static electricity are friction from the discharge tube, the kind of

chemical used, air temperature, humidity, etc.

Attach the insurance chain clip to the screw on the engine elbow. The chain should be allowed

to drag on the ground behind you. String the wire end along the discharge tube. Place the

wire at the 12 o’clock and 6 o’clock position on one end of the tube. Hold wire in place when

attaching the next tube.

Loading...

Loading...