5

STARTING THE UNIT

Starting the unit

Check the following items before starting sprayer:

1). Check the spark plug gap. Should be set at 0.024”-0.028”

(0.6mm-0.7mm).

2). Spark plug should be tight in hole.

3). Air filter should be clean.

4). Check if engine rotates freely by pulling the starter 2-3 times.

Add fuel to gas tank. Engine must be off while fueling.

Fuel is leaded or unleaded gasoline mixed with 2-cycle engine

oil. Unit comes with a gas mix container. Fill gasoline to the lower

line on the container. Add the 2-cycle oil to the top line. Your fuel

mixture is correct. The engine is designed to run on 25:1 or 30:1

fuel mixture.

Add chemical to chemical tank

For liquid chemical, the fluid on/off switch must be in the off

position. Screw the fill cap on tightly.

For dusting chemical, the dust valve and fuel lever should be in the

bottom position. Clean off the tank threads first, and then screw

the fill cap on tightly. Keep people and pets away from open end of

hose.

Cold engine starting procedure.

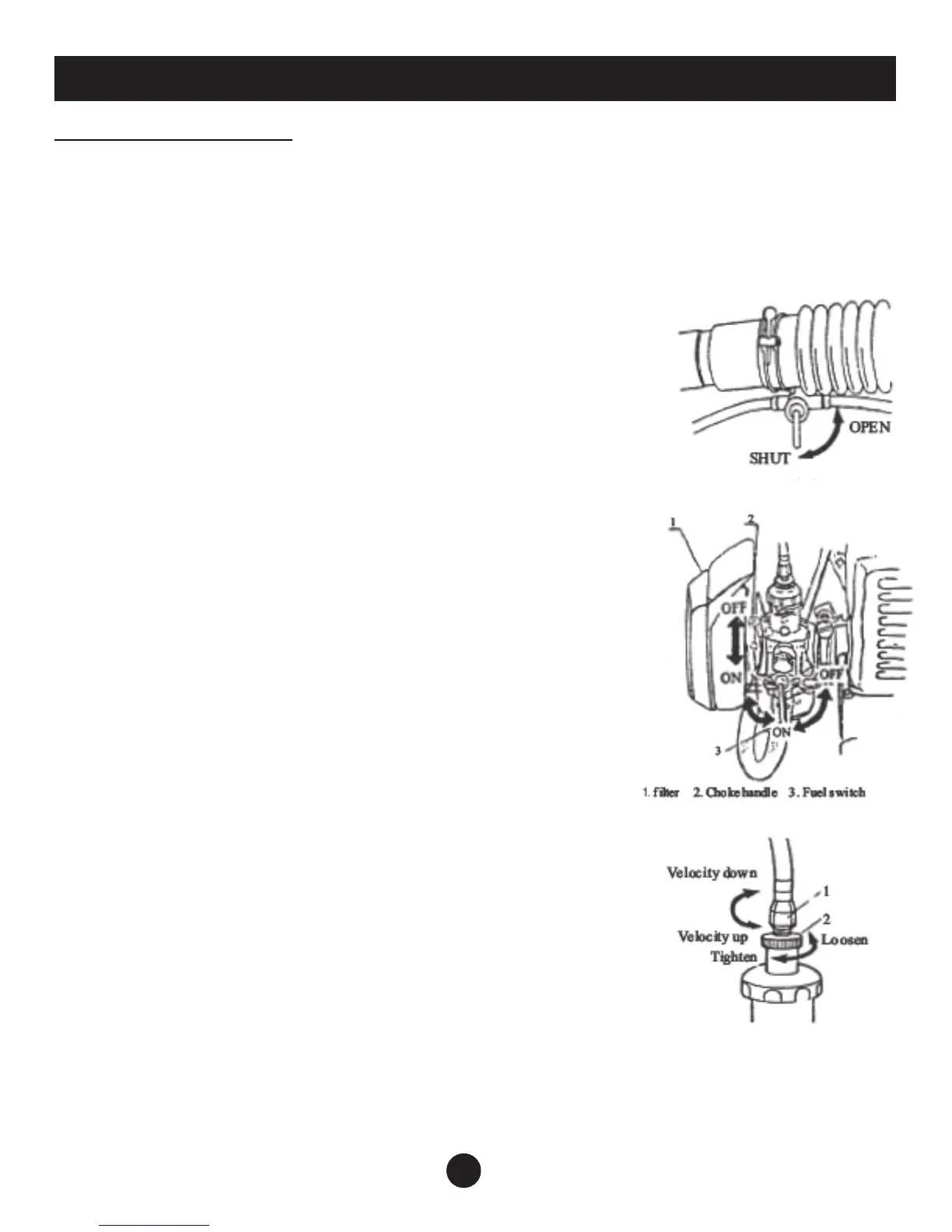

1). Turn on the fuel switch.

2). Set the red handled throttle in the start position.

3). Open choke on the engine.

4). Pull recoil starter a few times. Do not let go of pull handle,

guide it back to starter. Letting go of the pull handle can cause

damage to the engine when the starter is recoiling.

5). Set choke to half and pull starter handle until engine fires.

6). After engine starts, fully open choke.

7). Let engine run for 2-3 minutes before misting or dusting

operation.

Warm engine starting procedure.

1). Leave choke fully open.

2). If the engine draws in too much fuel, close fuel lever. Pull

starter handle 5-6 times to clear the fuel. Open fuel lever. Resume

starting engine from step 5 of the cold engine starting procedure.

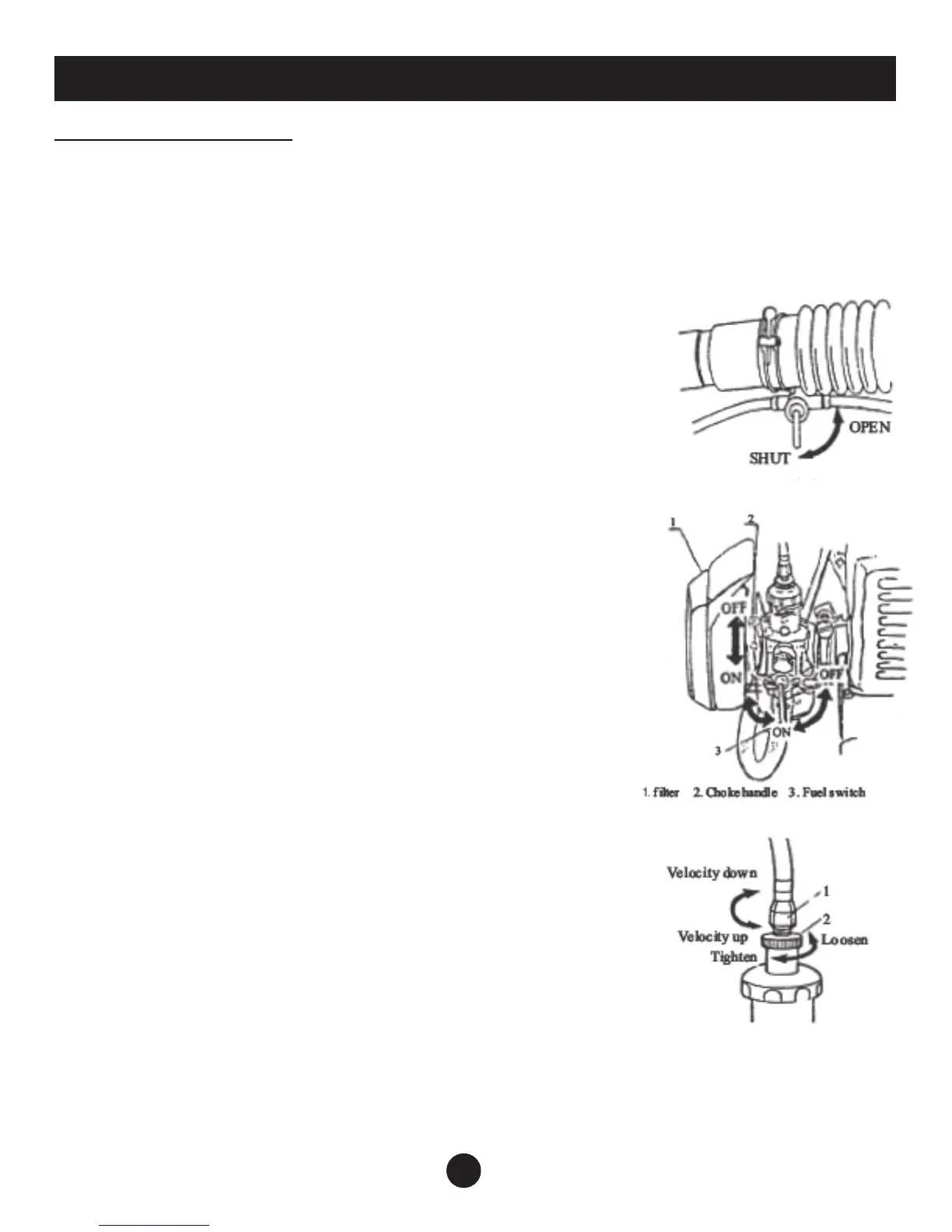

Speed adjustment.

If the engine bogs down too easily or does not stop with the

throttle at the lowest setting, the speed will need to be adjusted.

The speed control is located at the top of the carburetor.

1). Loosen the lock nut.

2). Turn the regulating screw counterclockwise to adjust velocity

up or clockwise to adjust velocity down.

3). Tighten the lock nut when satisfied with result.

Loading...

Loading...