TRANSMISSION—OVERDRIVE

35

Install the free wheeling cam snap ring on the main

shaft. This snap ring is serviced in three different sizes

.063", .068", and .073". Select the thickest ring which will

fit into the retaining groove (Fig. 11). Proper selection of

the snap ring will reduce end play to a minimum.

Reinstalling the Ring Gear and Main Shaft

Replace the ring gear on the overdrive main shaft and lock

it in place with a snap ring (Fig. 10).

This ring is serviced in three different sizes .055",

.057", and .059". Select the thickest ring which will fit into

the retaining groove. Proper selection of the snap ring will

reduce end play to a minimum.

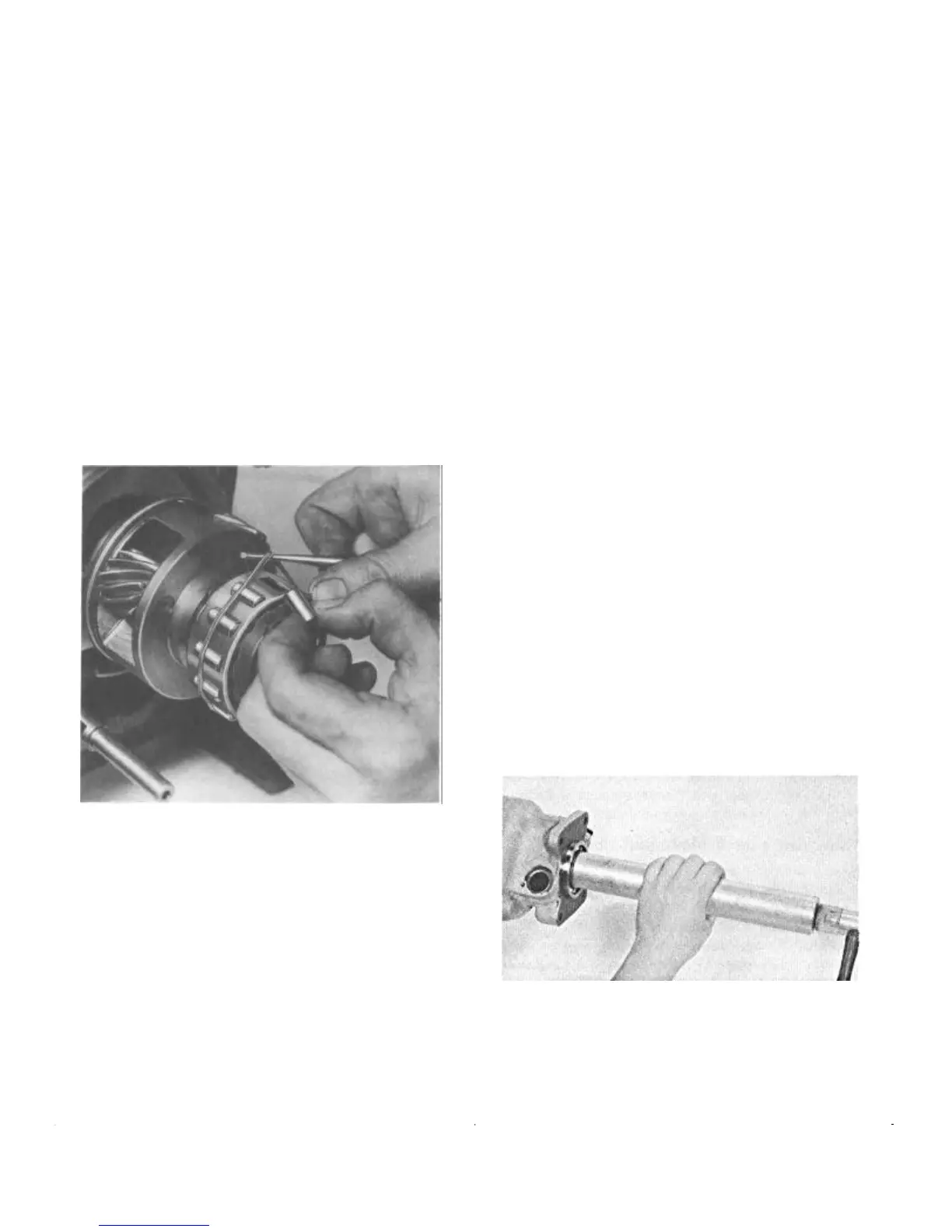

The Free Wheeling Rollers

Replace the free wheeling rollers in the free wheeling cam

retainer. A rubber band placed around the rollers will help

to keep the rollers from dropping out while the main shaft

and ring gear is being installed (Fig. 32).

FIGURE 32—A Rubber Band Serves to Hold

the Free Wheeling Rollers in Position

until the Ring Gear and Main

Shaft can be Installed

Now rotate the cage and roller assembly counterclock-

wise so that the rollers will be at the bottom of the cams.

This will permit the installation of the overdrive main shaft

and ring gear assembly.

Installing Speedometer and Governor Drive Gears

Insert the Woodruff Key into the main shaft. Then the

governor and speedometer drive gears. The governor drive

gear which is smaller in diameter is installed against the

shoulder on the main shaft.

NOTE: On a standard transmission, the speed-

ometer drive gear is retained in position by two

lock rings in addition to the Woodruff Key.

Reinstalling the Overdrive Case, Control

Lever, and Shift Shaft Assembly

Install the shift shaft oil seal and retractor spring in the

overdrive case.

Holding the bearing adapter to the transmission case

work the overdrive case onto the overdrive assembly.

Secure the assembly with the four attaching cap screws.

Push the shift shaft into the case so that the operating

cam will engage with the slot in the shift rod. Then install

the lock pin to hold the shaft in position.

NOTE: Inspect the operation of the shift lever

as follows: With the lever against the machined

stop on the boss of the case, a slight free move-

ment with no tension should be evident. Exces-

sive movement with no tension indicates that the

shift rod is binding in the case.

Installing Solenoid and Governor

Insert the solenoid plunger in the opening in the bearing

adapter and engage it with the notch in the locking pawl.

Turn the solenoid one-quarter turn counterclockwise to

lock the pawl and plunger together. Pull the solenoid to be

sure the plunger is locked with the pawl. Then tighten the

two cap screws.

Thread the governor unit into the overdrive case.

Tighten sufficiently to prevent oil leakage.

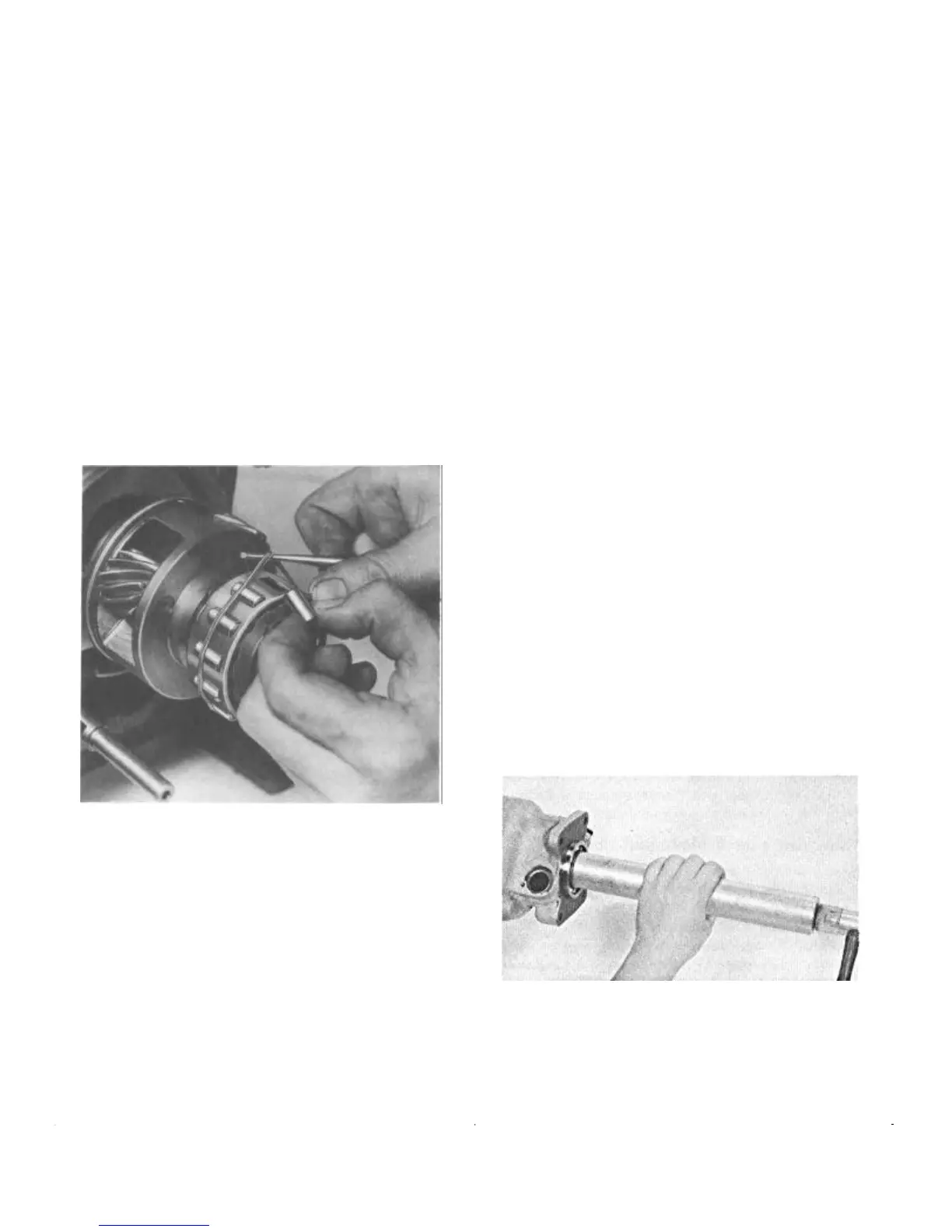

Reinstalling Rear Bearing, Oil Seal,

and Adapter

Install the rear bearing on the overdrive main shaft using

Tool J-2995 (Fig. 33).

FIGURE 33—Installing Rear Bearing

Install the rear spacer washer and snap ring (Fig 6).

NOTE: On the standard transmission, the rear

bearing is a press fit between the overdrive case

and torque tube and oil seal adapter.

Loading...

Loading...