34 TRANSMISSION—OVERDRIVE

Install the first and reverse sliding gear on the main shaft

with the shifting collar to the front.

Install the second speed gear on the main shaft with the

tapered cone to the front.

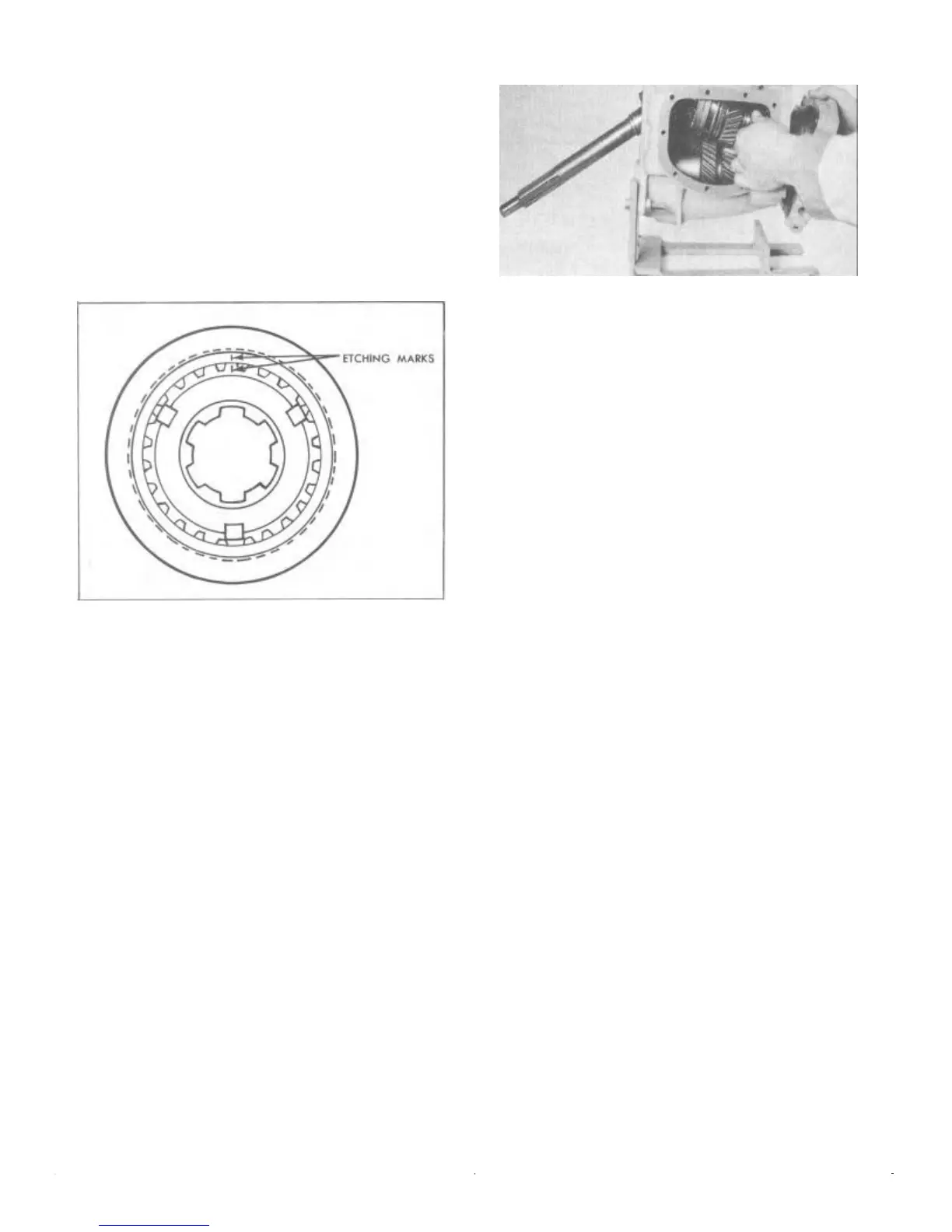

If the synchro-clutch was disassembled, check for

proper assembly. The hub section and the outer ring of the

synchro-clutch assembly are matched and lapped when

fabricated by the manufacturer and are marked according-

ly. The etching marks will correspond when properly

assembled (Fig. 30) . This will insure smooth sliding

action when shifting into second and third speeds.

FIGURE 30—Transmission Synchro-Clutch

Unit Etching Marks

Install the synchro-clutch including friction rings onto

the main shaft.

Install the lock ring and spacer washer on the main

shaft. Refer to Figure 25 for proper parts sequence.

Installing Clutch Shaft Assembly

Insert the fourteen clutch shaft needle bearings in the rear

of the clutch shaft. A coating of heavy lubricant will retain

them in proper position.

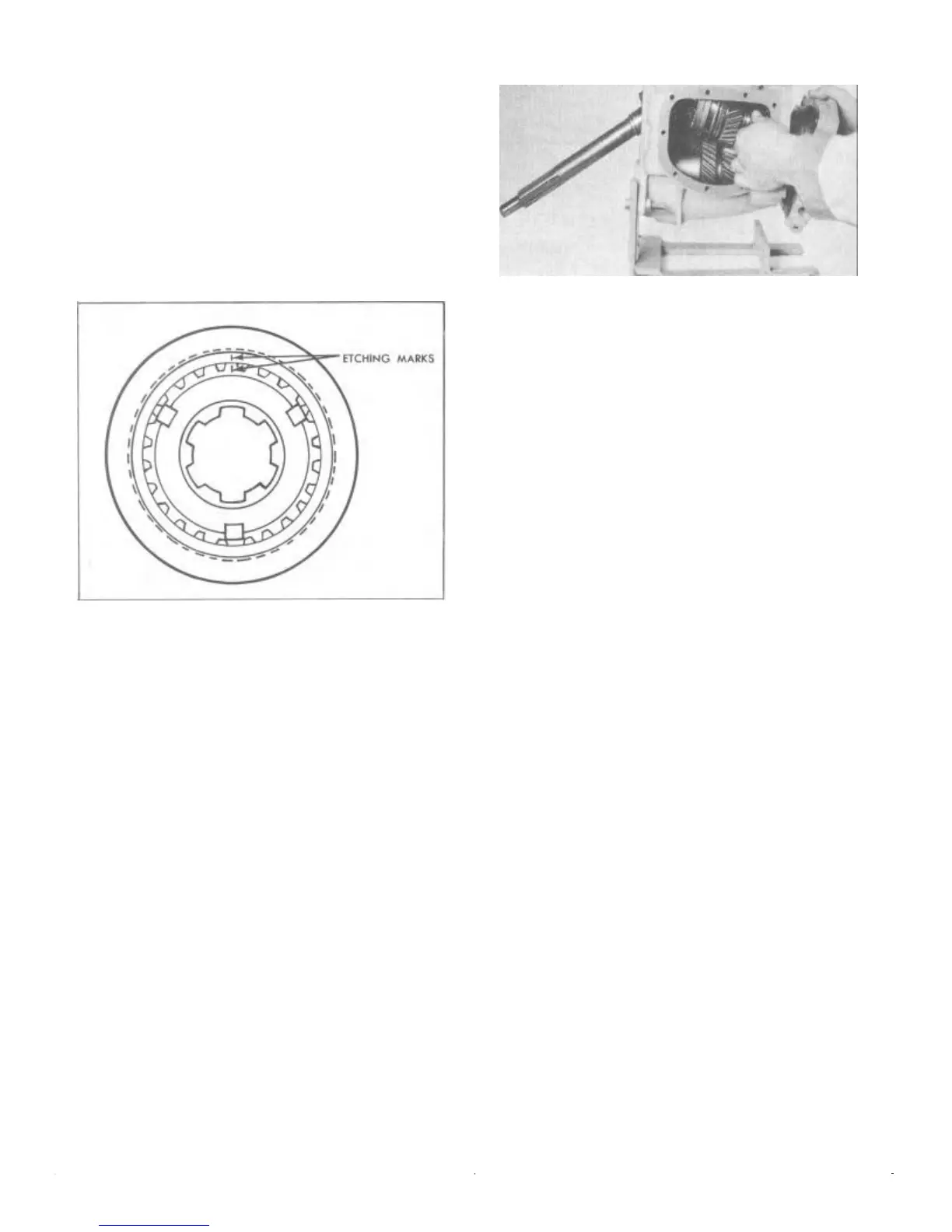

Insert the clutch shaft into the transmission case from

the rear. Position the shaft as shown in Figure 31.

Installing Main Shaft Assembly

Insert the main shaft assembly from the .rear of the trans-

mission case. It will be necessary to tilt the rear portion of

the assembly downward to provide the necessary clear-

ance to allow the synchro-clutch and second speed gear to

pass over the countershaft gear (Fig 31).

When the synchro-clutch just clears the countershaft

gear, place the clutch shaft in a horizontal position and

slide it onto the main shaft. Care must be taken to prevent

mislocation of the clutch shaft roller bearings. At that time,

place the clutch shaft and main shaft assembly in its proper

position in the transmission case.

FIGURE 31—Installing Main Shaft Assembly

Check the synchro-clutch friction rings for proper location

and freeness.

REASSEMBLING THE OVERDRIVE

When all parts have been carefully inspected the unit is

ready for reassembly. As each part is assembled, be sure it

is absolutely clean and lubricated with light engine oil.

Always use new gaskets, oil seals and snap rings in reas-

sembly.

Reinstalling the Hub and Balk Ring,

Locking Pawl, and Cover Plate

Install the hub and balk ring assembly with the chamfered

side of the ring against the sun gear hub.

Install the locking pawl, positioning the pawl and balk

ring in the "locked-out" position, with the pawl on the step

of the ring for correct installation of the solenoid.

Install the cover plate and trough in position and lock it

in place with the large snap ring.

This snap ring is serviced in three different sizes .0625",

.0665", and .0705". Select the thickest ring which will fit

into the retaining groove. Proper selection of the snap ring

will reduce end play to a minimum.

Reinstalling the Sun Gear and Shifter

Rod Assembly

Install the fork of the shifter rod in the sun gear shift collar.

Then hold them together as you slide the sun gear onto the

main (spline) shaft and the shifter rod into the opening in

the bearing adapter (Fig. 13).

Reinstalling the Pinion Cage and Cam

Install the pinion cage lock ring on the main shaft (Fig. 12).

Install the pinion cage assembly on the main shaft being

careful not to distort the oil slinger. The pinion cage

pinions mesh with the sun gear and the cage will butt up

against the lock ring previously installed.

Position the free wheeling cam on the main shaft so that

the counter bore of cam slides over the machined surface

of the pinion cage.

Loading...

Loading...