TRANSMISSION—OVERDRIVE

33

REASSEMBLY

When reassembling the transmission, always use new

gaskets and oil seals.

Reinstalling the Countershaft Gear and

Shaft

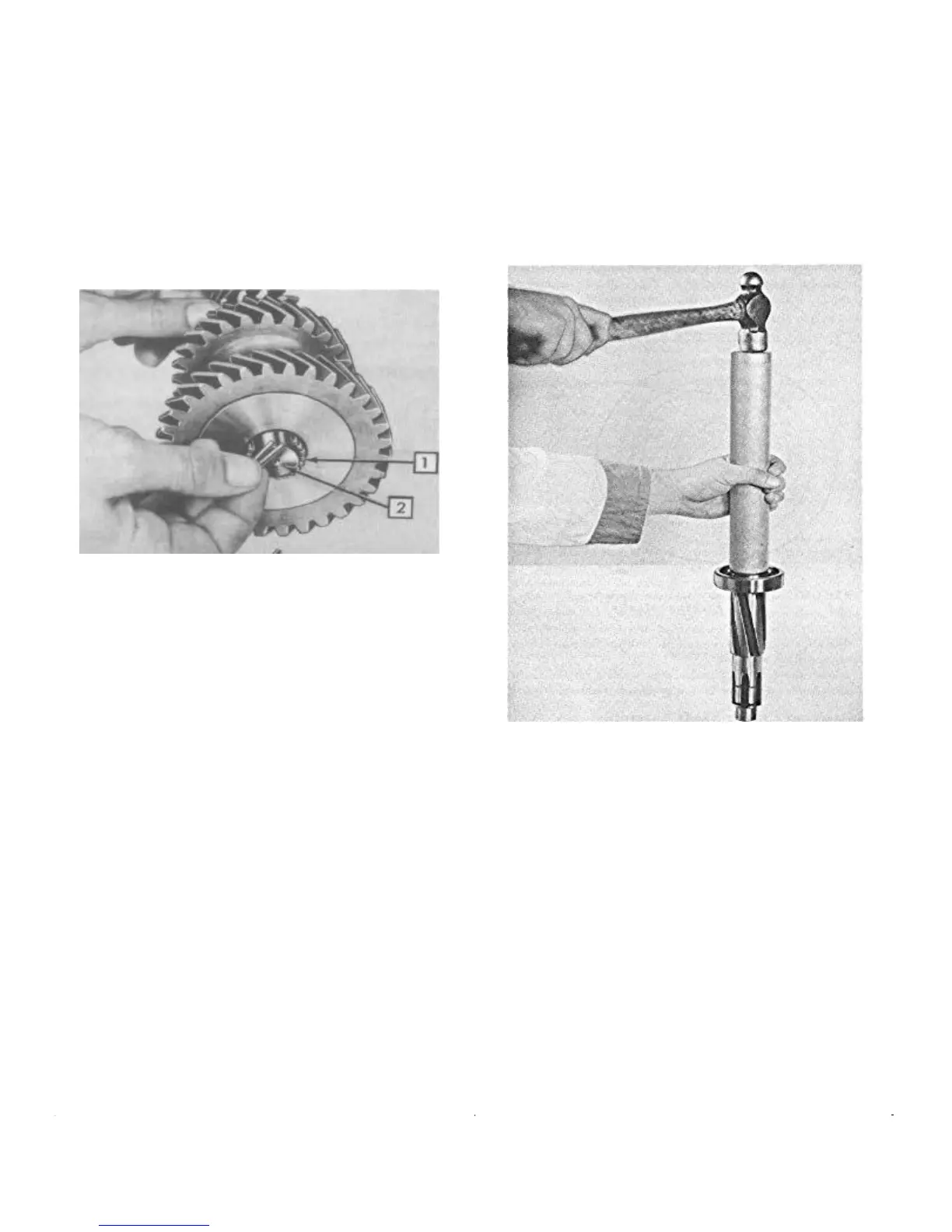

To hold the countershaft needle bearings, spacer, and

washers in place while installing the countershaft gear, use

a dummy shaft machined to .870" x 8-1/16" (Fig. 28).

1. Needle Bearings 2 . Dummy Shaft

FIGURE 28—Reassembly Countershaft

Gear Needle Bearings

After installing the bearings in the countershaft gear

and holding it in such a manner so as not to drop the

dummy shaft, install the thrust washers. The two small

projections on the face of the bronze rear thrust washer

must index with the grooves in the countershaft gear. The

front bronze thrust washer must index with the transmis-

sion case. Position the large thrust washer and install the

assembly in the bottom of the case.

Reinstalling the Reverse Idler Gear

Install the reverse idler gear with the chamfered side of the

teeth to the front of the ease.

Align the gear and install the reverse idler gear shaft

from the rear of the case. The shaft is a press fit into the

case, therefore, care must be taken to prevent damage to

the shaft. Install and align the Woodruff Key into the shaft

prior to driving the shaft flush to the rear face of the case.

Lift and properly align the countershaft gear. Prior to

installing the shaft, check the front and rear thrust washers

for proper alignment. The countershaft is a press fit into

the transmission case,

the transmission case, therefore, care must be taken to

prevent damage to the shaft. Install and align the Woodruff

Key prior to driving the shaft flush to the rear face of the

case.

Assembling Main Shaft Assembly

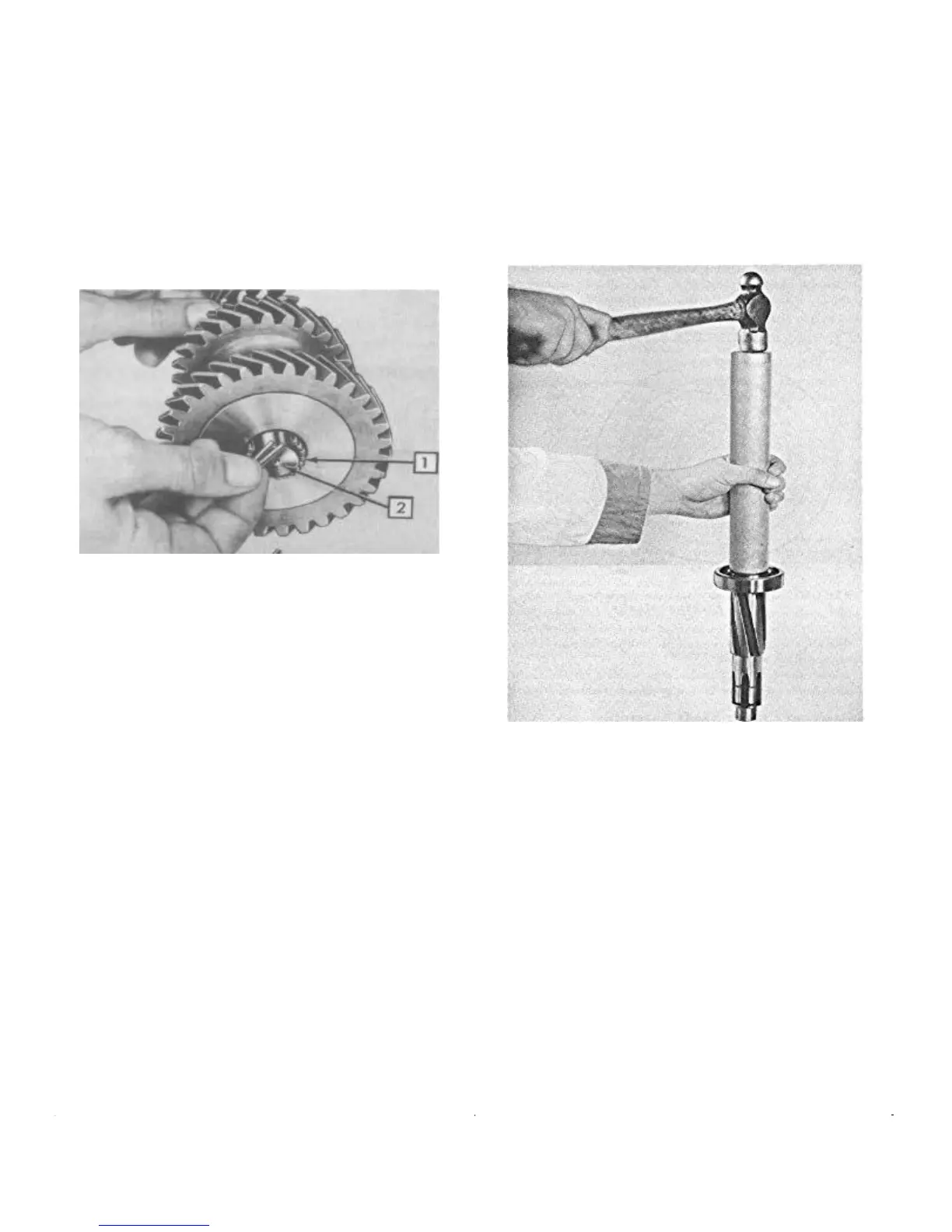

Install the transmission center bearing on the main shaft

using Tool J-2995 (Fig. 29).

FIGURE 29—Installing Center Bearing on

Transmission Main Shaft

Install the main shaft snap ring. This snap ring is ser-

viced in four different sizes .087", .090", .093", and .096".

Select the thickest ring which will fit into the retaining

groove. Proper snap ring selection will reduce end play to

a minimum.

Place the oil baffle into the overdrive adapter housing

with concave side facing forward.

Tap the main shaft and center bearing assembly into the

housing.

Install the large snap ring into the retaining groove of

the adapter housing. This snap ring is serviced in five

different sizes, .088", .091", .094", .097", and .100". Select

the thickest ring which will fit into the retaining groove.

Proper snap ring selection will reduce end play to a mini-

mum.

Loading...

Loading...