32 TRANSMISSION—OVERDRIVE

Where the ball bearing in the adapter requires replace-

ment, remove the large snap ring in the bearing adapter.

Tap out the main shaft and bearing from the adapter.

Remove the oil baffle from the adapter. Then remove the

main shaft snap ring and press the bearing from the main

shaft.

Removing the Clutch Shaft

Remove the clutch shaft from the rear of the transmission

case and remove the 14 needle bearings and oil baffle.

Removing Countershaft and Reverse Idler Gears

The countershaft and reverse idler gear shaft are a press

fit into the case. They are also locked into position at the

rear by Woodruff Keys.

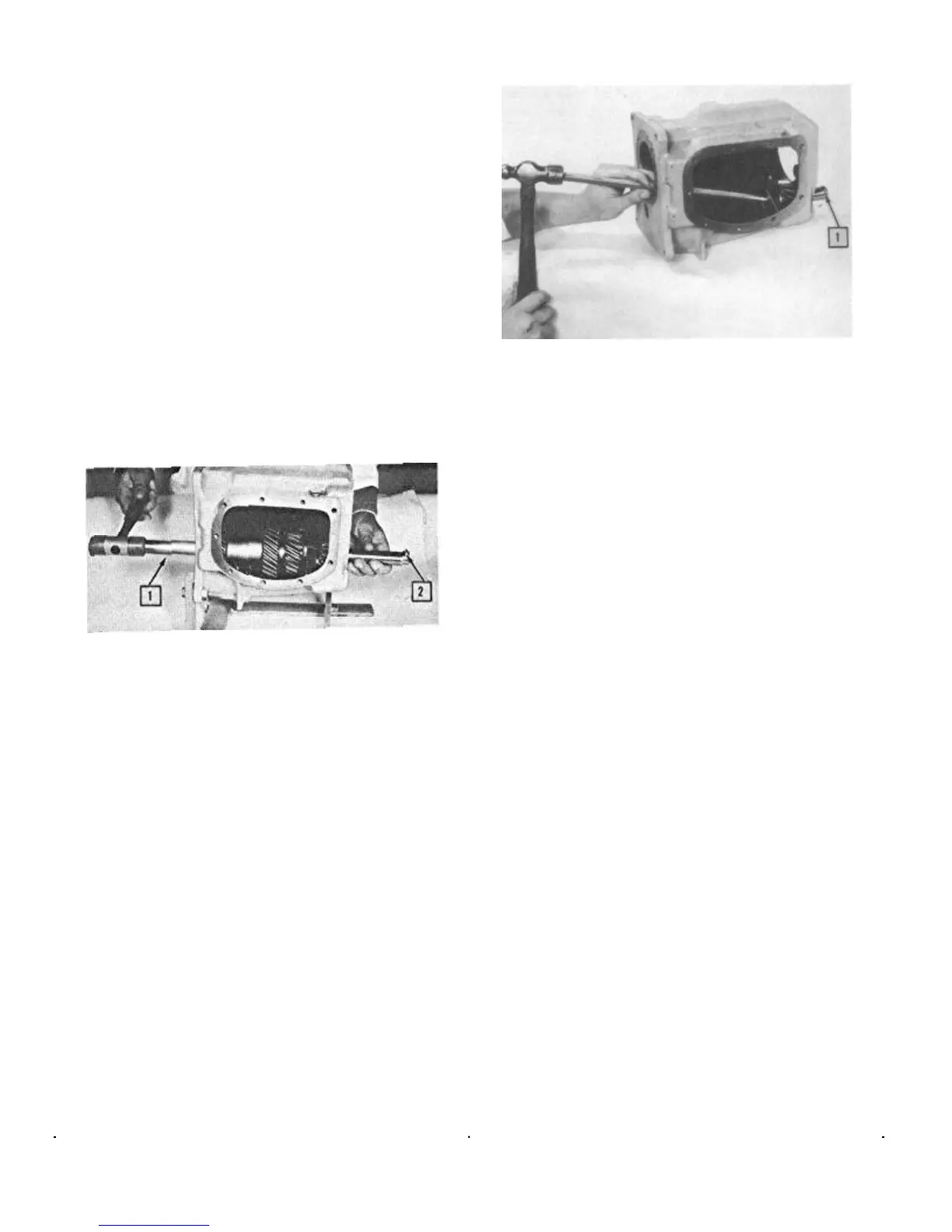

To maintain the position of the 80 needle bearings in

the countershaft gear, drive the countershaft out of the

rear of the case using a dummy shaft machined to .870" x

81/B" (Fig. 26).

1. Dummy Shaft 2. Woodruff Key

FIGURE 26—Removing Countershaft

With the countershaft removed, the countershaft gear

will drop to the bottom of the case. The countershaft gear

with needle bearings, spacer, washers, and thrust washers

may then be removed through the rear of the transmission

case as an assembly. If necessary, disassemble for inspec-

tion and parts replacement.

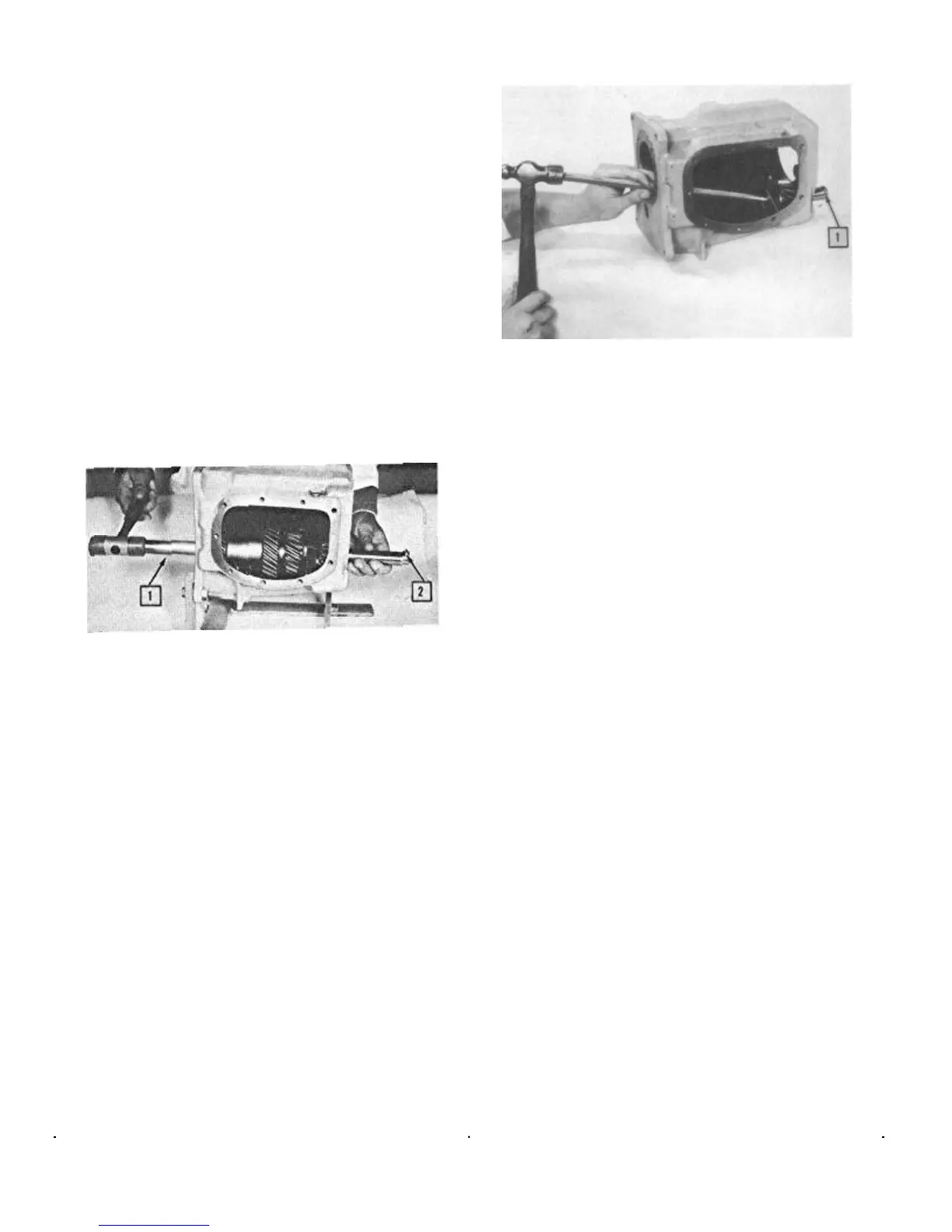

With the use of a brass drift, knock out the reverse

idler gear shaft through the rear of case (Fig. 27).

CLEANING AND INSPECTING PARTS

With the transmission completely disassembled, all parts

should be carefully cleaned so that they can be thoroughly

examined.

Gears

Wash all gears in a cleaning solution. Inspect for worn or

chipped teeth. Slide each gear onto a new shaft. If it

appears to be loose, it must be replaced.

NOTE: Whenever any transmission gear re-

quires replacement, the gear with which it

meshes should be replaced also.

1. Woodruff Key

FIGURE 27—Removing Reverse Idler Gear

Bearings

Bearings must be handled with great care. Wrap them in

a clean cloth or paper until they can be washed.

To wash a bearing, submerge it in a cleaning solution

that is absolutely free of dirt and rotate it to flush away all

oil and dirt. Dry the bearing with care.

Carefully examine each bearing for cracked races,

worn, or scored balls.

Main Shaft

Install the gears onto the main shaft to be sure they slide

on and off easily. The should fit smoothly without exces-

sive play between the splines. If the fit is tight, look for

burred edges on the splines.

Synchro-Clutch and Friction Rings

Carefully inspect the synchro-clutch and friction rings.

Slide the rings on the cones of the second speed gear and

the clutch shaft. Replace rings if there is excessive wear

on the taper.

Transmission Case

Examine the surfaces of the bearing recesses in the trans-

mission case for wear or scoring which indicates that the

bearing has been revolving in its housing. Examine the

case for cracks or other defects.

Be certain that all parts of the case are thoroughly clean

before and during assembly.

Clutch Housing.

Examine the housing for cracks or other defects.

Check the rear face of the clutch housing with a dial

indicator. The total run-out should not exceed .005".

The total run-out of the clutch housing bore should not

exceed .003".

Loading...

Loading...