Installation Manual 3000B Page 2 of 9 May 2012

Long T-Handle Allen Wrench Set (3/16” to 3/8”)

Medium Size Flat Head Screw Driver

Brass Ball Peen Hammer

Flat Bastard File

240 Grit Sand Paper

Anti-Seize Lubricant

WD-40

12” Crescent Wrench

Shop Towels

Exact-A-Pitch

®

Digital Protractor (P/N 62375)

25 ft. Measuring Tape

Pencil or Marker

Open/Box End Wrench Set (1/2” – 1-1/2”)

Socket Set for 1/2” Drive (1/2” – 1-1/2”)

Torque Wrench(s) Rated for 0-200 ft-lb

Retainer Ring Tool (Hudson Provided)

RECOMMENDED TOOLS

INSTALLATION PROCEDURES

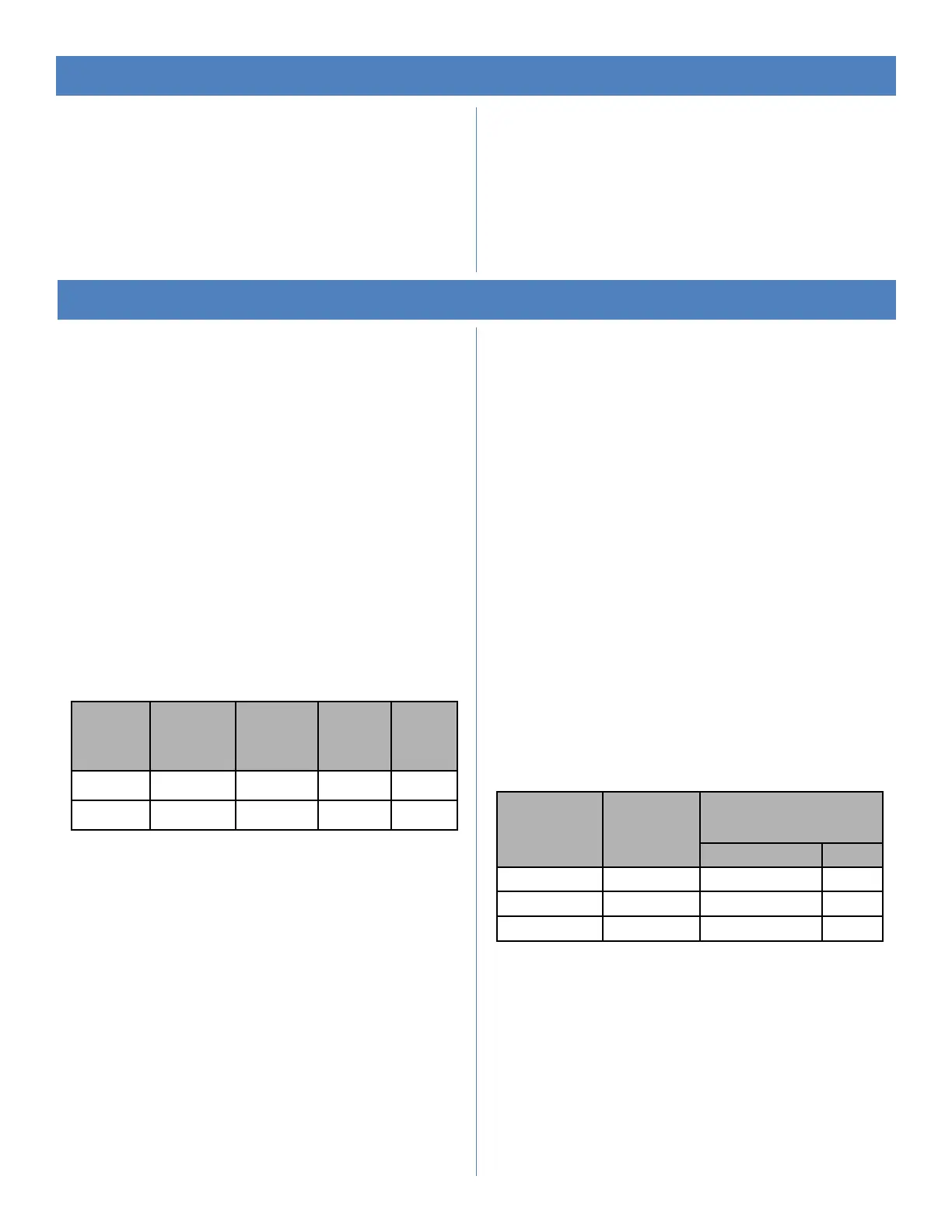

Bushing

Size

Allen

Wrench

Size

Cap

Screw

Size

Socket

Size

Torque

(ft-lb)

Dry

Q2 - 3/8” 9/16” 29

R2 3/16” 3/8” 9/16” 29

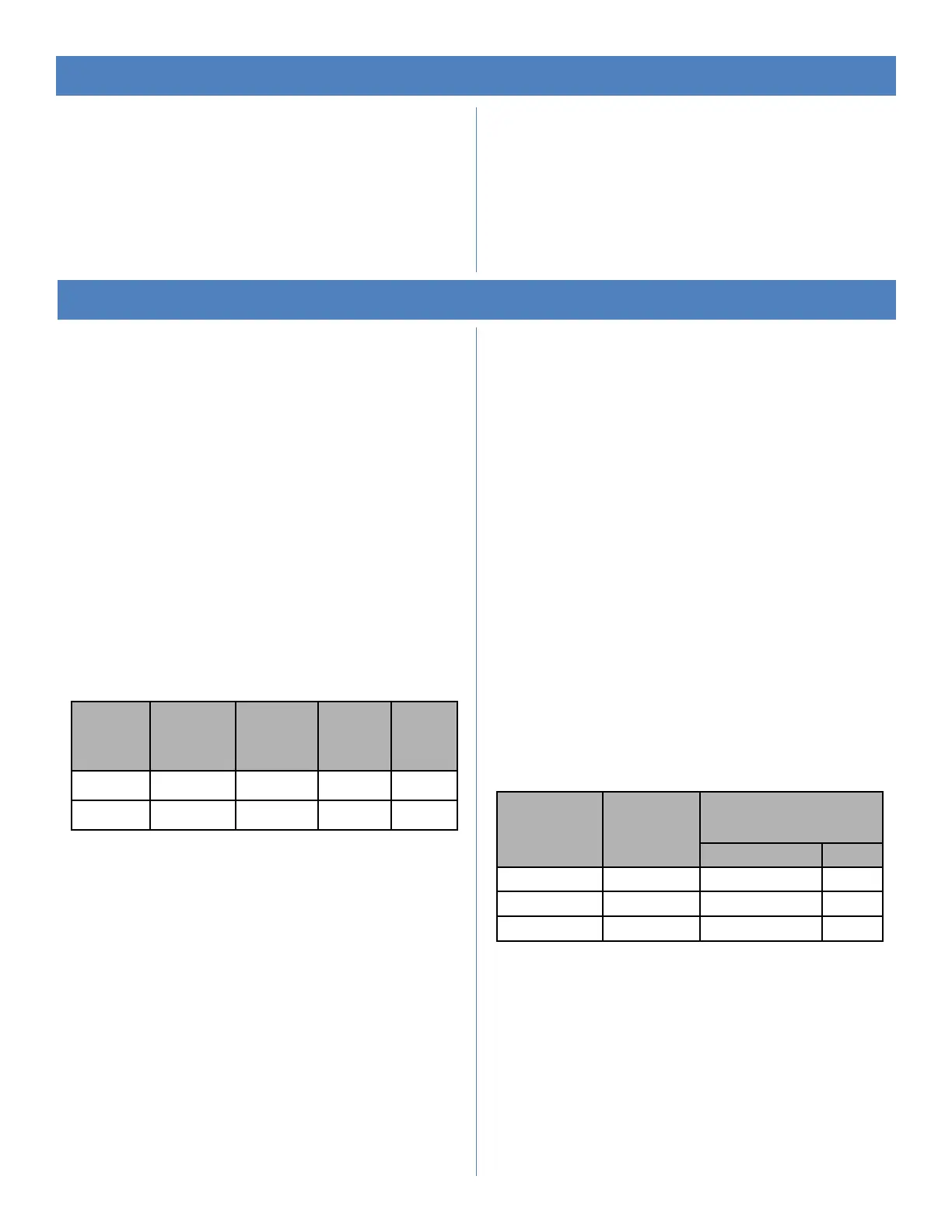

Cap Screw

Size

Socket

Size

Torque Value

(ft-lb)

Lubricated Dry

5/8” NC 15/16” 70 90

3/4” NC 1-1/8” 125 130

1” NC 1-1/2” 150 160

ASSEMBLY WITH BUSHING

Clean all mating surfaces between hub, bushing and shaft. All

grease and lubricant should be removed, leaving the mating

surfaces dry.

If there is no shoulder on shaft to prevent bushing from sliding

down shaft, slide spacer/sleeve (not provided) on shaft before

bushing or use a thrust retainer (optional equipment) on top of

hub. Slide bushing and key onto shaft until flush with end of

shaft. The shaft size determines the bushing type (Q2 or R2).

Lock bushing on shaft by tightening the set screw in flange

with an Allen Wrench. (Note: Q2 bushings have no set screws.)

Line up key and set hub on bushing. Engage the three (3) cap

screws in flange of bushing into hub spool, using a torque

wrench with a socket, and tighten evenly. Use the following

table to determine the proper tools and torque values.

ASSEMBLY WITH STRAIGHT SHAFT

(NO BUSHING)

Clean all mating surfaces between the hub and the shaft. If

there is no shoulder on shaft to prevent hub from sliding down

shaft, slide spacer/sleeve (not provided) on shaft before hub or

use a thrust retainer (optional equipment) on top of hub. Install

key in shaft. Line up key and keyway and set hub on shaft.

Tighten set screw(s) in hub.

ASSEMBLY WITH TAPERED SHAFT

(NO BUSHING REQUIRED)

Clean all mating surfaces between the hub and shaft. Coat all

mating surfaces with an anti-seize or lubricating compound.

Align keyways and install hub. Install retainer plate and cap

screw(s) with lock washer(s). Shaft size determines what size

cap screw is necessary. Using a torque wrench with a socket,

evenly tighten cap screw to recommended standard per table

below.

NOTE: Retaining arrangement varies with gear shaft design.

Loading...

Loading...