Installation Manual 3000B Page 5 of 9 May 2012

SET PITCH AND TRACK

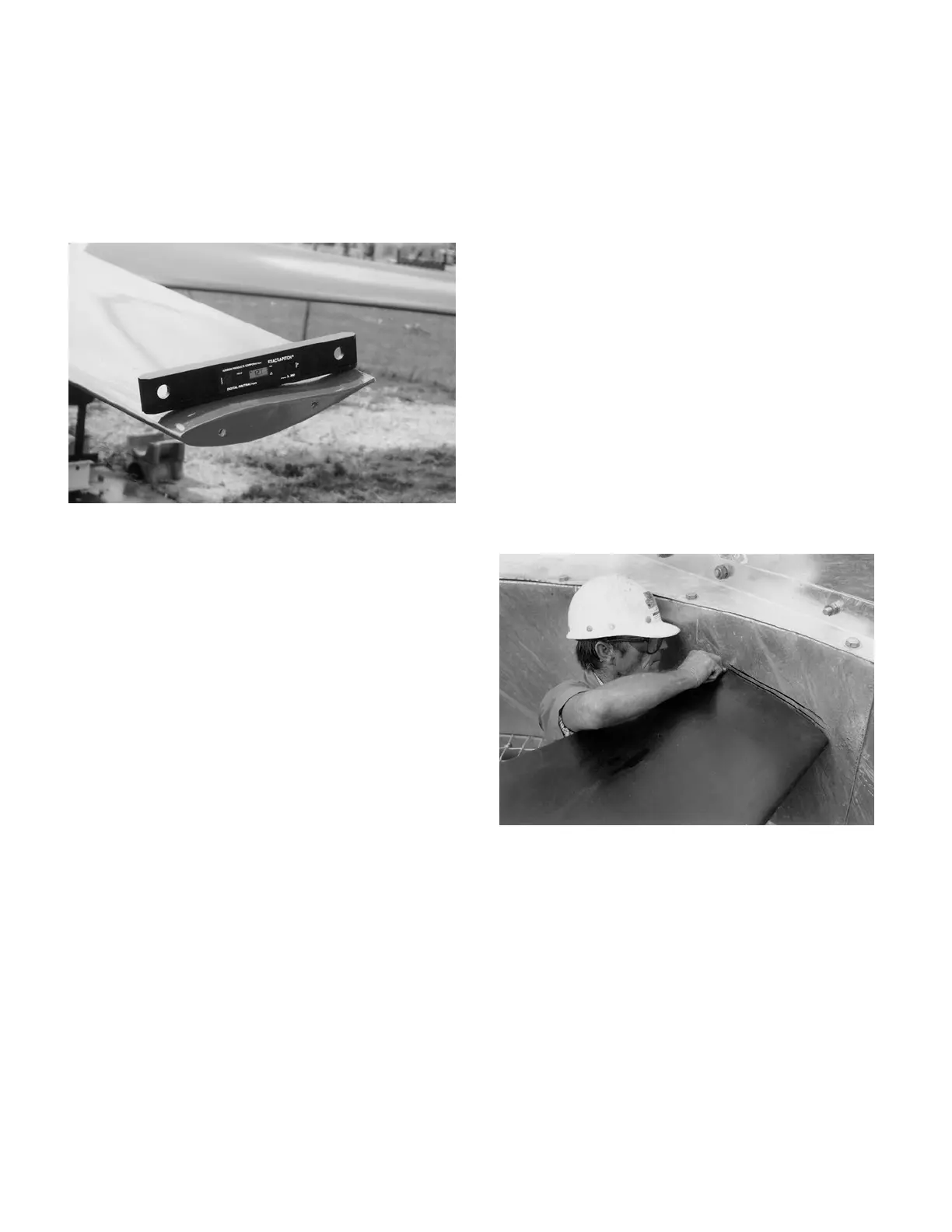

Use Hudson’s EXACT-A-PITCH

®

digital protractor (See Figure

6) or a bubble protractor to set blade pitch. Mount protractor on a

flat bar as a base and place it approximately 1” from tip of blade.

Note pitch on protractor. Rotate fan 360

º

, noting high and low

pitch readings. Locate place where pitch reading is at mid-point

between high and low readings, and set pitch at that point.

Rotate blade in socket until digital protractor shows specified

pitch angle to within +/-0.2

º

. Fan pitch angle is shown on fan

specification sheet for design duty. After desired pitch angle is

set, raise and lower end of fan blade and find mid-point of blade

travel. Hold blade at the mid-point and pull blade outward so it

sits against retainer rings.

Check to see that blade retainer rings are properly seated in both

hub and blades grooves. It may be necessary to back cap screws

off about one turn and re-tighten them in order to force ring to fit

properly in groove.

Start tightening the four blade socket cap screws by alternating

the sequence of tightening (like tightening lug nuts on a car

wheel). The torque applied to any one cap screw shall be no

more than 5 ft-lb, greater than the torque on any of the other (3)

cap screws during the tightening process. All cap screws are to

be tightened to 15-20 ft-lb. Make sure shoulder on blade neck fits

tightly into and against retainer ring. DO NOT OVERTIGHTEN

CAP SCREWS. After cap screws are tight, tighten jam nuts

against socket to 15-20 ft-lb.

Note B: If a severe duty retainer (SDR, Figure 5A) is used, it

may be necessary to loosen the SDR fasteners as necessary for

proper retainer ring seating at the outset. See cap screws labeled

as (3) in Figure 5B or 5C.

Figure 6

When bolts are tightened, hold a pencil against top end of blade

and mark the level onto a fixed object, such as a pole or the fan

ring.

Install remaining blades at same place as first blade, following

the instructions above. After tightening cap screws, mark top

end of each blade in same place first blade was marked. If

marks differ by more than 3/4”, adjust blade.

Note C: It is more important to positively seat the retainer ring

pair into the blade shank ring groove than to achieve perfectly

consistent tracking between all blades. If there is a conflict in

achieving both blade seating and blade tracking, ignore the

tracking specification.

CHECK TRACK

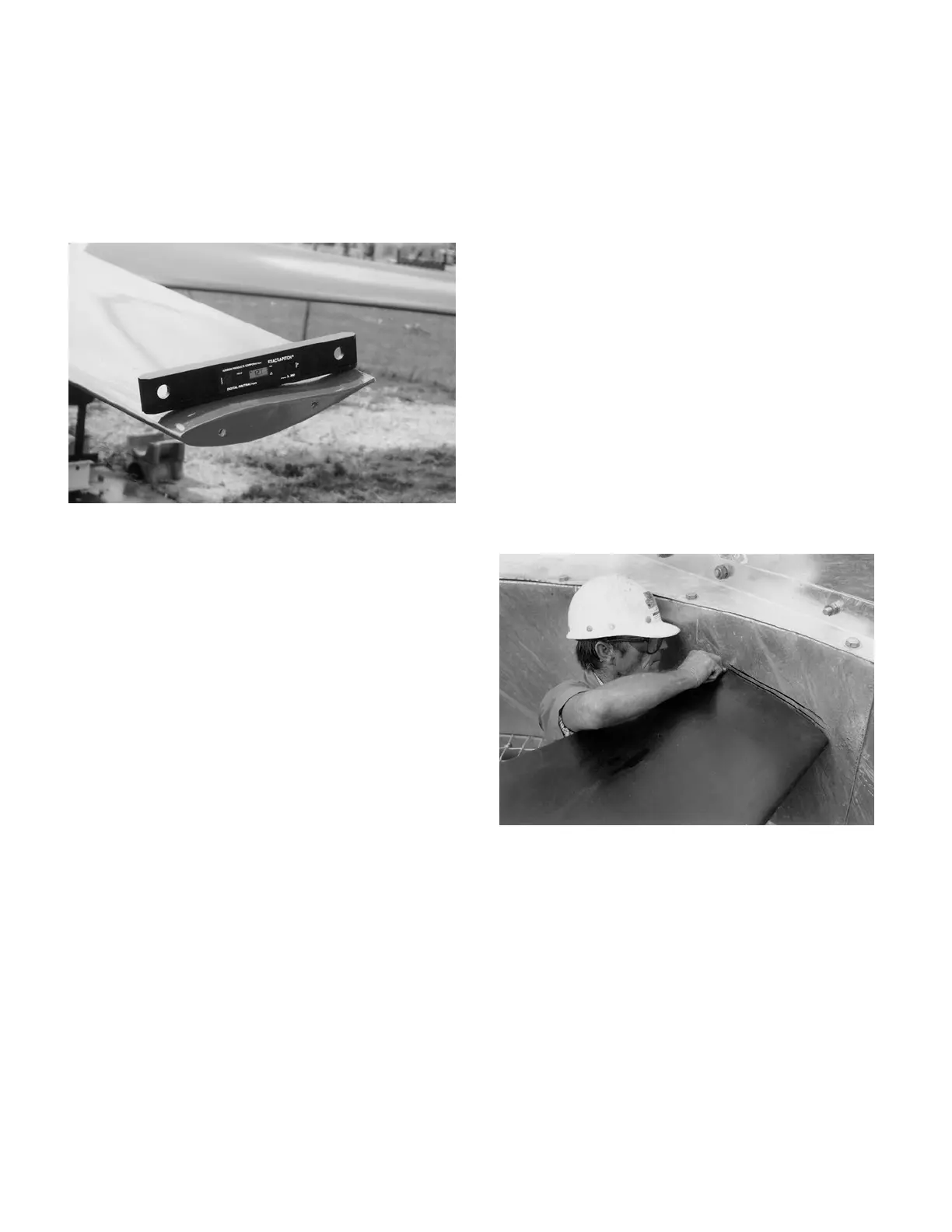

After fan is installed in fan stack cylinder ring, outline the top

side of each blade onto fan stack cylinder ring with a marker

(See Figure 7). The difference between levels of highest and

lowest outlines should not be more than 3/4”. To raise blade

track, loosen blade socket cap screws on top half of socket and

tighten cap screws on bottom half. To lower blade track, loosen

bottom screws and tighten top ones. Tighten 3/8” cap screws to

15-20 ft-lb torque. Re-tighten jam nuts after adjustment.

Note D: It is more important to positively seat the retainer

ring pair into the blade shank ring groove than to achieve

perfectly consistent tracking between all blades. If there is a

conflict in achieving both blade seating and blade tracking,

ignore the tracking specification.

Figure 7

Loading...

Loading...